9. SETTING THE WELDERS

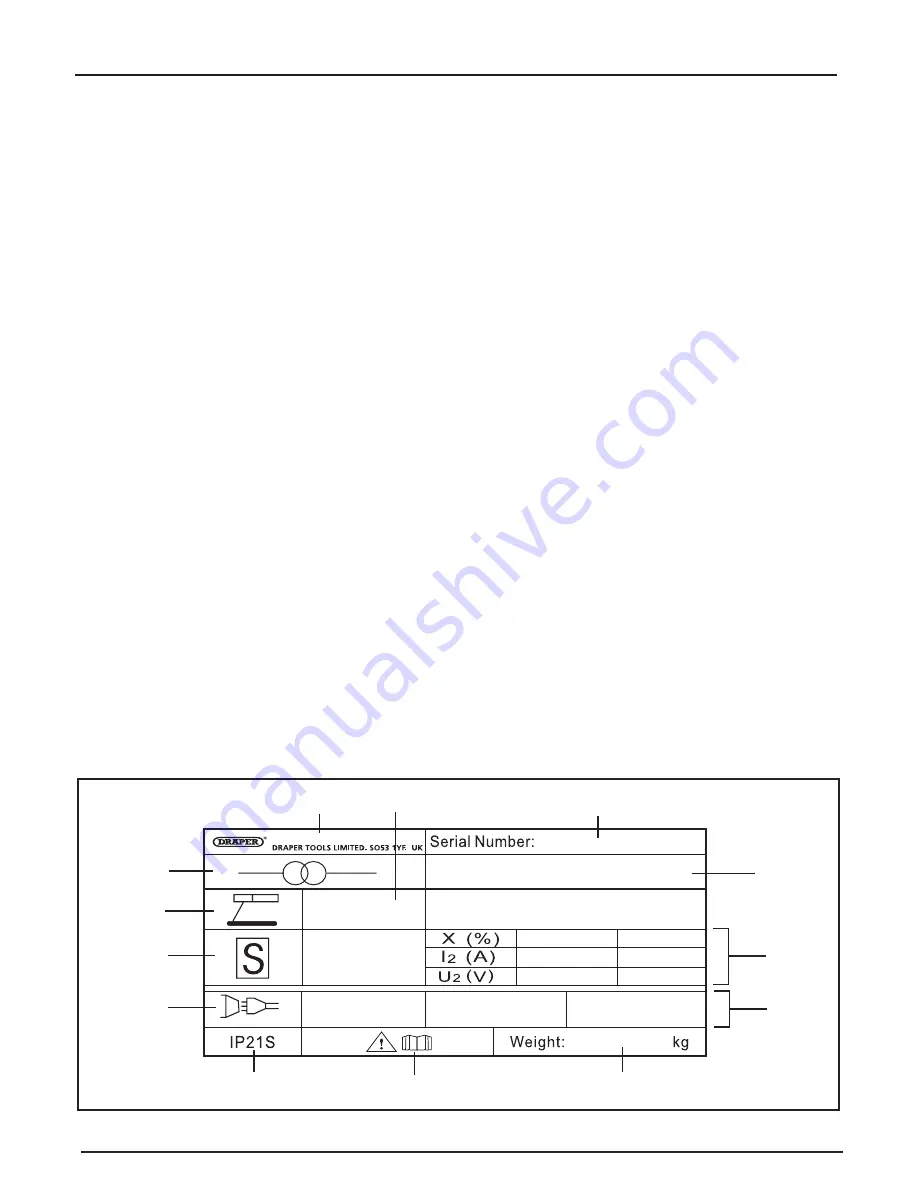

A data plate is affixed to the welding machine. Fig.1. shows examples of this plate.

$

Constructor name and machine part No.

%

Delivered alternate current frequency.

&

Serial number.

'

European reference standard for the construction and safety of welding

equipment.

(

WELDING CIRCUIT PERFORMANCE

U0V

Minimum and maximum open circuit voltage (open welding circuit).

Ø

Diameter of weldable electrodes.

I2A

Value of the current needed to weld using different electrode diameters.

A/V

Conventional welding current (maximum) and corresponding normalised

voltage.

)

POWER SUPPLY DATA

U1

Input voltage (permitted tolerance: +/- 10%)

I1 eff

Effective absorbed current.

I1 max

Maximum absorbed current.

*

Weight

+

Safety symbols.

,

Level of protection from solids and liquids.

-

Input power required:

1" alternate single phase voltage, frequency

.

Symbol indicating the possibility to use the welding machine in environments

potentially subject to electric discharges.

/

Indicates the machine is an ARC/MMA process machine.

0

Indicates this machine produces an AC welding current.

$

'

(

)

0

/

.

%

-

+

*

,

&

10

60

EN 60974-1

U

0

=46V

I

1max

= 36A

I

1eff

= 15.3A

~50Hz

~50Hz

60A/20.4V-160A/24.4V

1~

1~

160

65

24.4

20.6

Stock No.71090 Part No.AW164AT

U

1

=230V

FIG.1

13