– 14 –

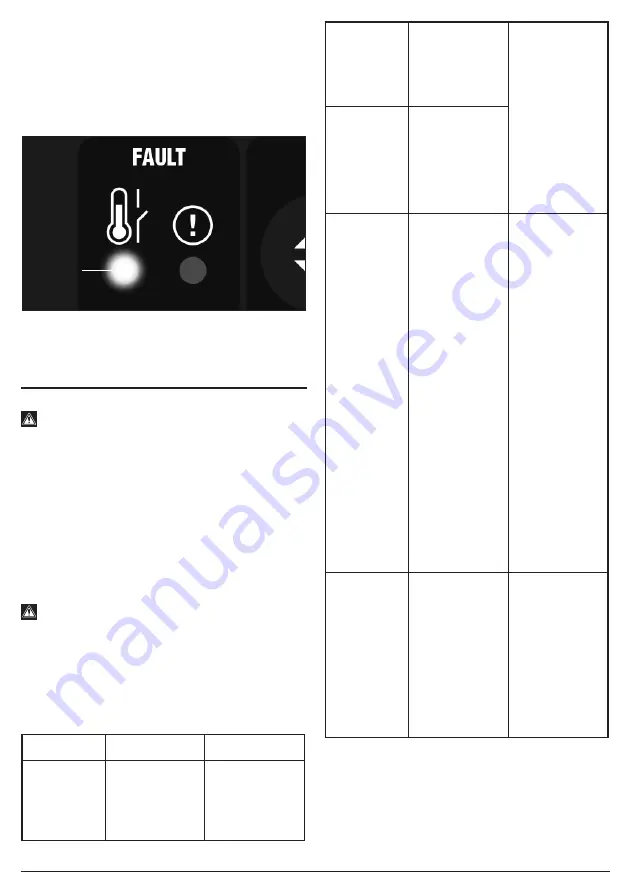

8.7 THERMAL CUT-OUT – FIG.13

If welding for extended periods, the thermal cut-out will

activate and the LED indicator

(M)

will illuminate,

prohibiting use of the machine until sufficiently cool.

Caution! After completion of any welding task, leave the

unit connected to the power supply for a sufficient period

to allow the cooling fan to continue working.

13

FIG.

9. MAINTENANCE AND

TROUBLESHOOTING

9.1 MAINTENANCE

Warning!

If the welding machine has just been turned off, you

must not conduct any internal checks or

maintenance for at least 5 minutes after the power

distribution box switch or power switch is

disconnected so that the capacitor inside the

welding machine is completely discharged.

− It is crucial to carry out regular checks on this product

to ensure optimum performance and safe operation.

− The inspection table below offers guidance for the

checking of components for general wear and tear or

damage. Wherever necessary, clean or replace such

items.

Warning! Any live electrical parts touched may

cause fatal electric shock or serious burns.

For your own safety, turn the switch off and remove the

plug from the power supply socket when carrying out

any form of maintenance or cleaning. If in doubt, consult

Draper Tools, or an authorised service agent.

Welding power supply:

Component

Check points

Advisories

Front panel

− Check if any

components

are

damaged or

loose.

Tighten or

replace where

necessary

Front panel

− Check if the

lower quick

socket is

loose.

The lower quick

socket is a

regular item. If a

defect occurs, it

will be

necessary to

check the

inside, re-fasten

or replace

components

where

necessary.

Rear panel

− Check if the

air intake of

the cooling

fan has

foreign

objects

sticking to it.

Routine

− Power on,

and then

check if the

appearance

has fading or

too hot

traces.

− Check if the

cooling fan

has stable

operation

sound.

− Check if the

cooling fan

takes in air

from the air

intake, if

odour,

abnormal

vibration or

noise

(especially

during

welding)

occurs.

In-case of

defects, it is

necessary to

check the inside

of the device.

Top plate,

bottom

plate and

side panel

− When the

machine

cover is

installed

onto the

housing,

check if it is

loose.

− Check if

bolts are

loose.

In case of

defects, it is

necessary to

replace or

fasten

components,

etc., as

required.

(M)

Summary of Contents for Expert 70052

Page 18: ......