EZ-Fold Basketball Backstops by Draper—Wall-Mounted

Page 4 of 18

www.draperinc.com

(765) 987-7999

Remo

v

e End Cap

Scre

w

5

/

16

-1

8

coarse thread

socket head cap scre

w

into

thread in end of motor shaft

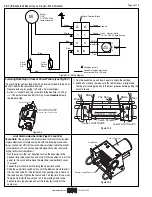

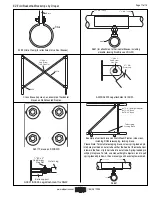

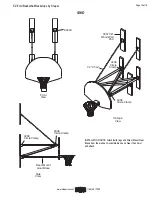

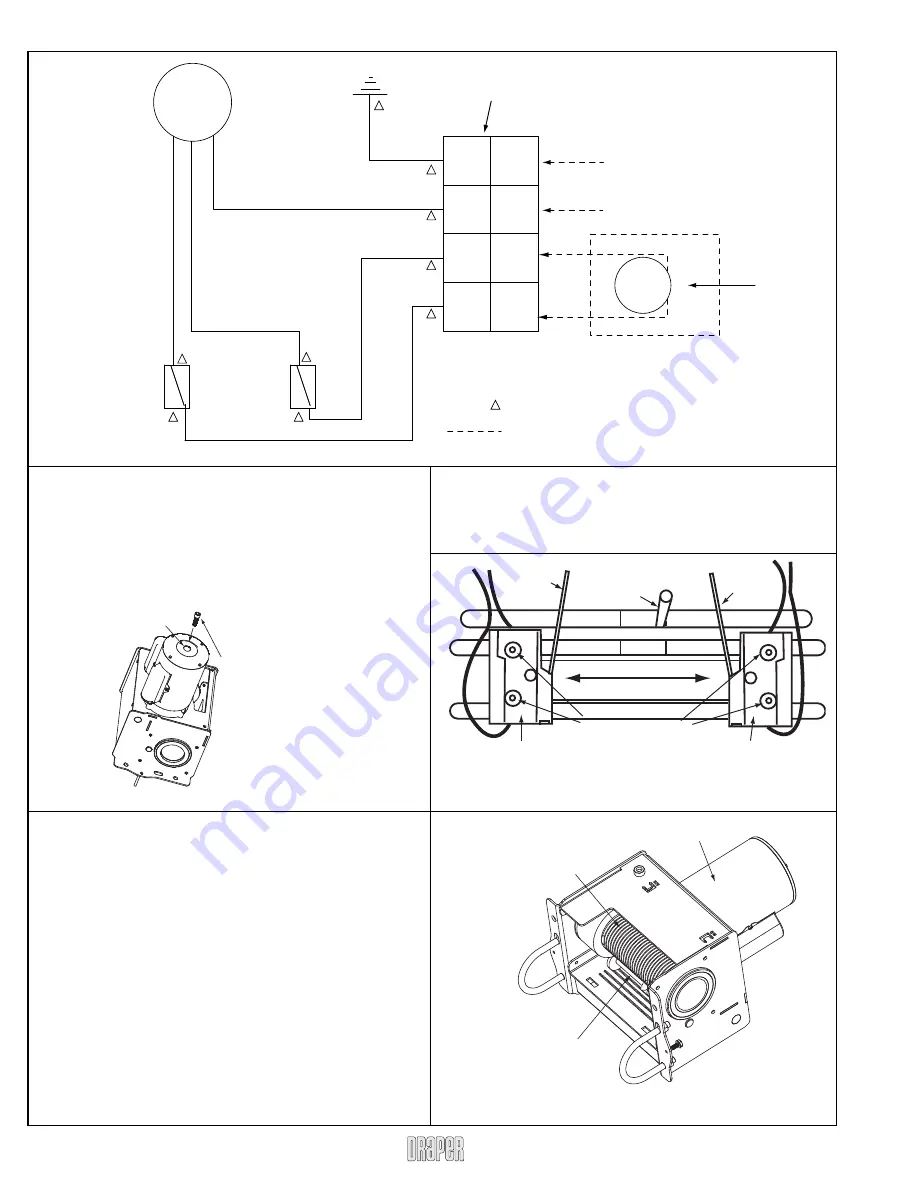

Lowering Backstop in Case of Power Failure (see Fig. W-4)

The winch motor comes standard with an internal thread in the end of

the shaft, behind the removable end cap.

➀

Remove end cap by prying it off with a fl at screwdriver).

➁

Screw

5

/

16

" socket head cap screw into threaded hole in shaft, or

5

/

16

"-18 coarse thread hex bolt. Turning screw

clockwise

slowly

lowers

backstop.

Figure W-4

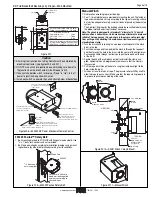

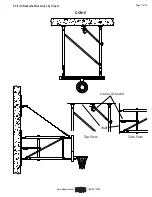

Figure W-5

HIGHER LOWER

Upper Limit Switch

Trip Rod

Thumb Screws

Blade

Lower Limit Switch

Blade

Red

Blue

Ca

b

le Dr

u

m

Spring-Loaded Tensioner

1 HP 110

v

Motor

Figure W-6

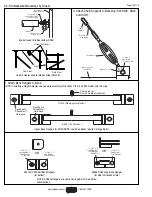

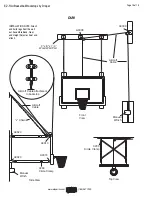

Limit Switch Adjustment (See Figs. W-5 and W-6)

Please Note:

One upper and one lower travel limit switch is provided.

Proper adjustment is simple and quick with the following procedure.

Always shut power off from the winch when working inside the electri-

cal compartment. The cover has been designed for quick removal to

simplify limit switch adjustment.

➀

Run the winch in the "up" direction to raise the backstop to the

desired (fully raised) position and stop it in this position. Turn off the

power to the winch and remove the electrical compartment cover.

(2

screws)

➁

Loosen the two thumb nuts holding the upper limit switch.

➂

Slide the upper limit switch across until the blade contacts the limit

trip rod, then slide it a little further until an audible click is heard as

the switch opens. Tighten the thumb nuts. The top limit it is now set.

➃

Temporarily install the cover and run the backstop down to the

desired lower stop position and set the lower limit switch in the

same

way.

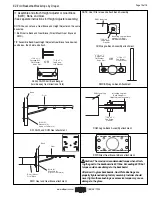

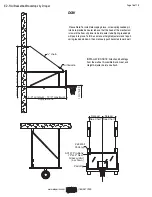

Figure W-3—Wiring Diagram

Dashed wiring by electrician

Limit

Switch

Up

Limit

Switch

Down

Red

Blue

M

Motor

1 HP

110-120V/1/60

Instant reverse

Line 1, Neutral, white

110-120 Volt, 20 Amp Service

G

G

8

8

4

4

1

1

Ground

use minimum No. 12/3 wire

DOWN

UP

Black

(Hot)

Green

White

Red

KEY

SWITCH

12

18

11

Wiring by factory

Blue

Blue/Black

Green

White

Red

Winch Terminal Block

➄

Run the backstop up and down again to check the settings.

➅

Make a fi nal check to make sure that all fasteners are tight and

the rope is tracking properly in the drum grooves before putting the

winch into use.