EZ-Fold Basketball Backstops by Draper—Wall-Mounted

Page 5 of 18

www.draperinc.com

(765) 987-7999

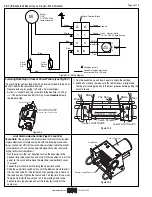

T

w

ist lock receptacle (3 prong)

4" s

qu

are

b

ox, and co

v

er plate

(all

b

y others)

10"

3½"

8

¼"

110-120

v

AC radio controlled

recei

v

er (1 pro

v

ided for

each

w

inch re

qu

ired)

Backstop or gym

di

v

ider selector s

w

itch

“Up-Do

w

n”

bu

ttons

Receptacle (4-prong) to

accept po

w

er/control ca

b

le

from 1 H.P. electric

w

inch

-Pl

u

g pro

v

ided

b

y man

u

fact

u

rer

66" long cord 14A

W

G3/CSJ

Hand held porta

b

le transmitter:

503020 – Operates

u

p to 9

w

inches

503021 – Operates

u

p to 27

w

inches

W

eight 7 oz.

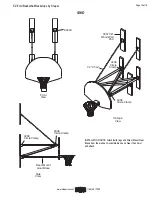

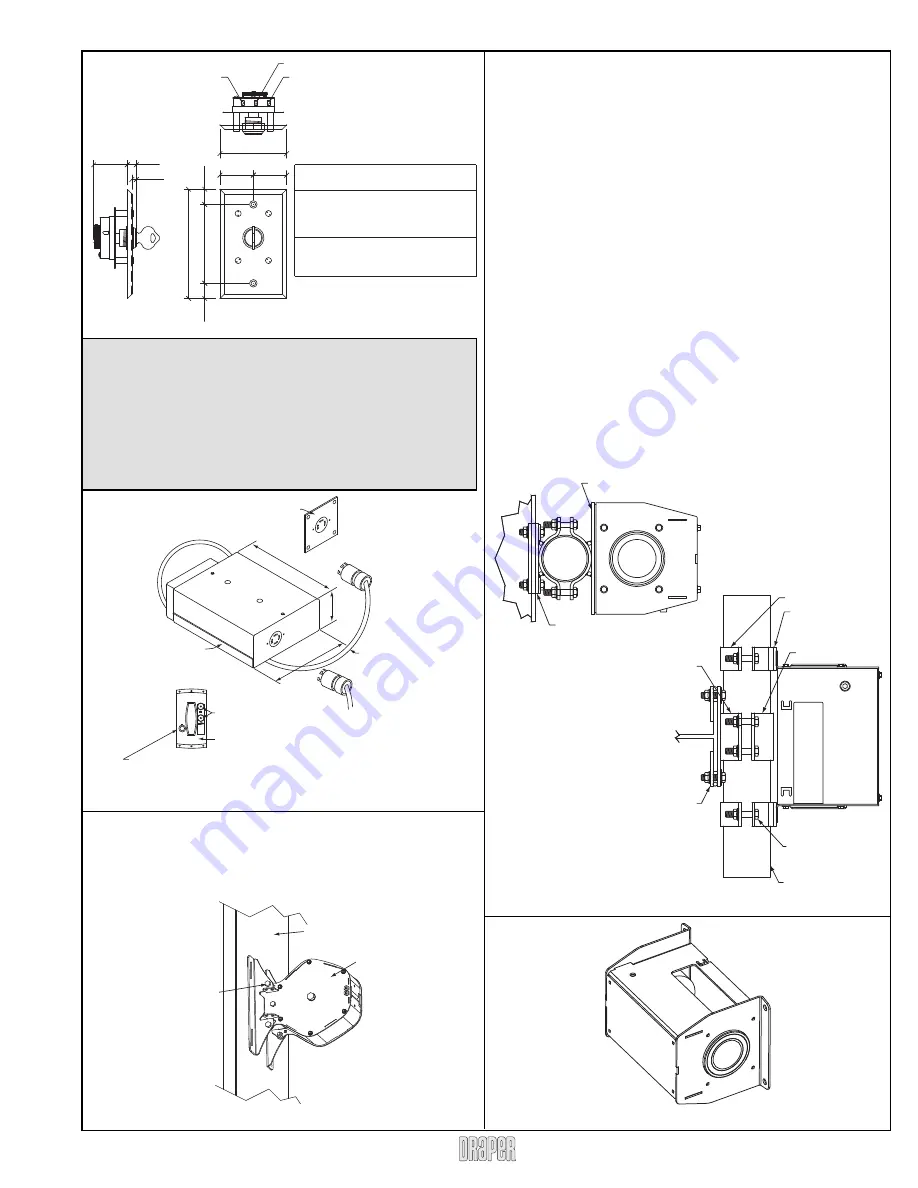

Figure W-7

Figure W-8—503023 EZ Power Electronic Remote Control

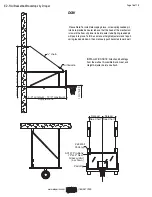

Caution

➀

All wiring from junction box to Key Switch must be completed by

electrical contractor (see fi gures W-3 and W-7).

➁

DO NOT wire winch into junction box until making sure power to

the

junc

tion box is disconnected (circuit breaker is off).

➂

If key switch operates winch in reverse (“Down” is “Up”), turn off

power to junction box and switch wires.

➃

Install key switch so operator has unobstructed view of backstops.

Circ

u

it

b

reaker rated amp. 20 amp.

F

u

sed circ

u

it rated amp. 20 amp.

Minim

u

m

W

ire Size

90

'

maxim

u

m r

u

n. . . . . . . . . 12 ga.

90

'

to 140

'

r

u

n. . . . . . . . . . . .10 ga.

O

v

er 140

'

. . . . . . . . . . . . . . . .

8

ga.

Sizes of

w

all masonry

b

oxes re

qu

ired

for single and ganged key s

w

itches--

All

b

oxes 2" (

w

) x 3¾" (h) x 2½" (d).

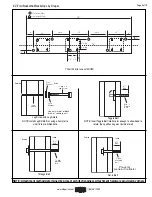

1

3

/

8

"

3

/

8

"

3

/

16

"

1

3

/

8

"

1

3

/

8

"

4

1

/

2

"

3

1

/

4

"

5

/

8

"

5

/

8

"

2

3

/

4

"

12 (Do

w

n)

11 (Black/Hot)

1

8

(Up)

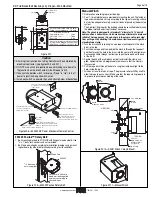

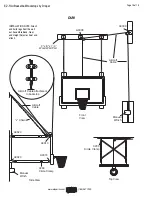

Manual Winch

➀

Find location according to project drawings.

➁

Four

9

/

16

" diameter holes are provided for mounting the unit. The fastener

type and size required will vary according to the type of mounting surface

but must be adequate to safely sustain all loads imposed by the backstop

system.

The Architect/ Engineer for the building should be consulted to determine

the proper method and size of fastener necessary.

Note: The winch is designed for standard ¼" diameter 7 x 19 aircraft

cable and has a hollow drum, which makes rope attachment simple and

reliable. The rope passes through a hole in the drum and is prevented

from pulling out by doubling the end back on itself and securing with a

standard rope clamp.

➂

Turn the winch handle to bring the wire rope mounting hole in the winch

drum to the top.

➃

Pass the wire rope end from outside the winch in through the rope port

and then through the hole in the drum, into the center of the hollow drum.

Pass enough cable through to allow you to pull the free end out the end

of the drum.

➄

Double the end of the cable back on itself and install the clamp sup-

plied, tightening the nuts progressively to make sure that the clamp is

fully

secured.

➅

Pull the rope back through the hole to snug the clamp back tight to the

hole, inside the drum.

➆

Wind on at least two turns of rope. (The pressure roller will lift by itself to

allow the rope to pass under.) Make sure that the rope starts properly in

its groove, to ensure even winding of the cable.

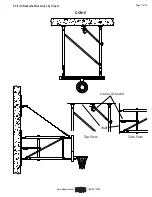

Figure W-10—A0481 Winch Column Mount

503029 Posilok™ Safety Belt:

➀

Bolt mounting brackets to POSILOK with fl anges turned outward. Use

3

/

8

" x 1" bolts, lock washers and nuts provided.

➁

Bolt to wood wall pads according to installation drawings using mount-

ing hardware (by others) determined according to site conditions.

Figure W-9—503029 Posilok Safety Belt

Figure W-11—Manual Winch

W

ood Pad

503029

Hard

w

are to attach to

w

ood

w

all pad s

u

pplied

b

y others according to

site conditions

3

/

8

"

b

olts and

n

u

ts (s

u

pplied)

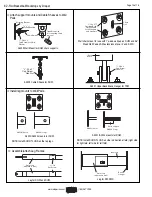

4" x 2" Half Clamp

A0481

Bracket

4" x 4" Half Clamp

A0340

Spacer

Flat

1/2"-13 x 2"

Grade 5 Cap Screw

& Flange Lock Nit

Typ. (8) places

TOP VIEW

4" O.D. Tubing

A0481

Bracket

A0340

Clamped to column

SIDE VIEW