Section 2 -

Idler-End and Operator End Assemblies

Please Note:

The operator will already be installed in the operator-end roller; the sliding pin idler will also be installed in the idler-end roller. It is only necessary to

install the coupler assemblies.

Caution:

Section 1.1 - 2"

(51 mm)

Idler-End Assembly

Please Note:

Notches in the tube need to be lined up with the "keys" on the

couplers.

1.

Insert coupler assembly into roller. Ensure the notch in the tube is lined up with

the "key" on the coupler, and press until the assembly is fully seated in the roller.

Section 1.2 - 2"

(51 mm)

Operator-End Assembly

Please Note:

Operator-end coupler assemblies will not slide straight in to the roller

tube.

1.

Insert assembly into the roller, with the "key" slightly off center from the notch.

2.

Once assembly is far enough in that the ribs are past end of the notch, rotate the

coupler until the notch is lined up with the "key" on the coupler.

Please Note:

If the assembly will not fully seat in the roller, retract the shaft

(if

applicable)

and tap the assembly with a rubber mallet. Be careful not to damage the

coupler.

Section 1.3 - 3"

(76 mm)

Idler-End Assembly

Please Note:

The retractable shaft needs to be pointing toward

the opposite end of the motor and oriented that direction for the whole

unit.

1.

Insert coupler assembly adapter into roller. Making sure the notch in

the adapter is lined up with the notch in the coupler, press until the

adapter is fully seated in the roller.

2.

Insert coupler assembly into adapter. Making sure the notch in the

inside of the adapter is lined up with the "key" on the coupler, press

until the assembly is fully seated.

Section 1.3 - 3"

(76 mm)

Operator-End Assembly

1.

Follow the same steps used for the idler-end.

Please Note:

If the assembly will not fully seat in the roller, retract the

shaft

(if applicable)

and tap the assembly with a rubber mallet. Be careful

not to damage the coupler.

•

Ensure the locking ring on the idler-end coupler assembly

is fully tightened before installing roller into brackets.

There should be no play in the locking ring. If the locking

ring is loose, then the idler is in "height adjustment" mode.

•

Wear a heavy glove on the hand

used to grip the locking ring.

•

Tighten the locking ring until it is fully locked and it

cannot rotate any further. Ensure it is tight and will

not work loose. If locking ring cannot be tightened by

hand, use a flat screwdriver or other tool to assist.

OR

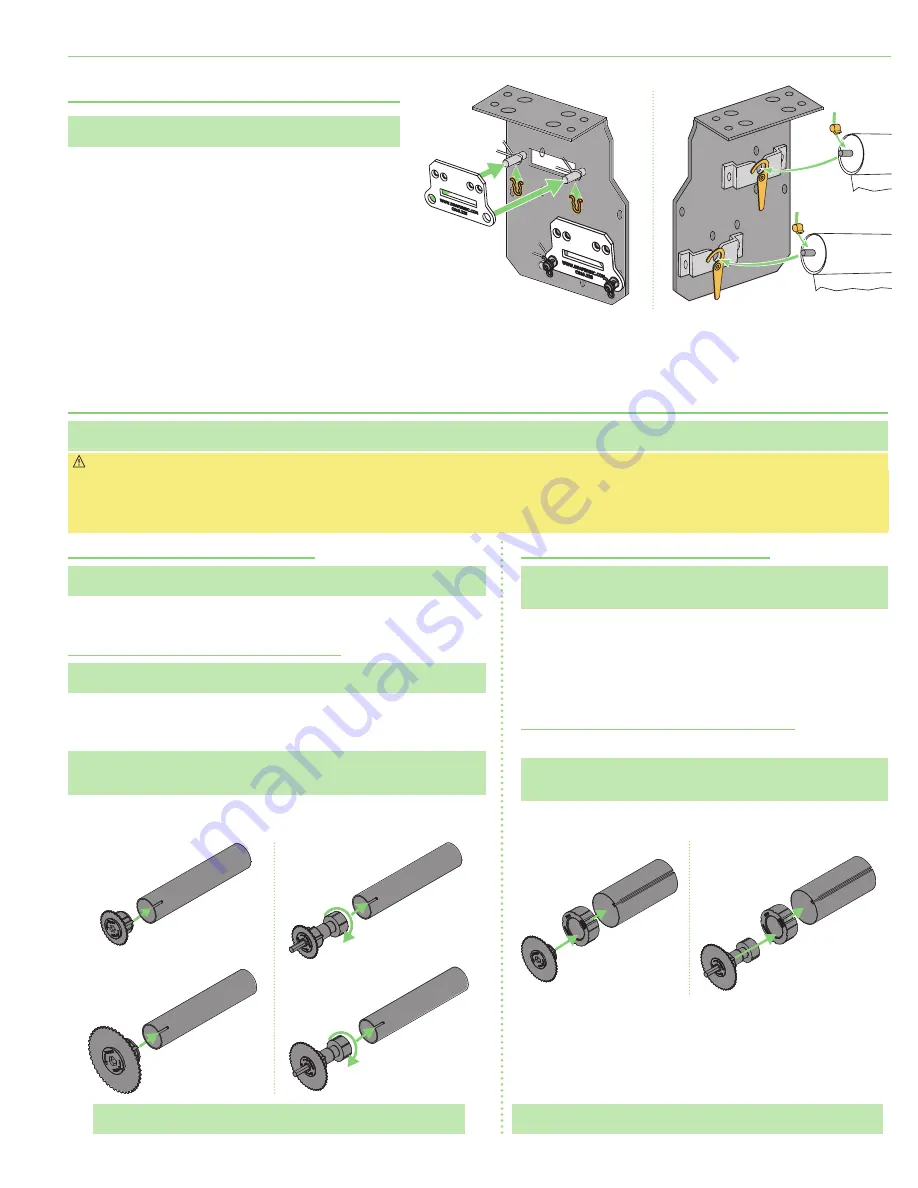

C177.059SA

C177.062SA

OR

C177.058SA

C177.061SA

Idler End Coupler

Operator End Coupler

C103.069

C177.061SA

AND

C103.069

C177.062SA

AND

Idler End Coupler

Operator End Coupler

Figure 2-A

Figure 2-B

Please Note:

The retractable shaft must point toward the opposite end of

the motor and oriented in that direction for the entire unit.

Please Note:

The retractable shaft must point toward the opposite end of

the motor and oriented in that direction for the entire unit.

Section 1 -

Mounting Brackets

Please Note:

Installer is responsible for selecting mounting

hardware appropriate for site conditions.

1.

Mark wall, jamb, or ceiling for placement of mounting brackets.

2.

Drill small starter hole

(if necessary)

in mounting surface.

3.

Mount brackets using appropriate fasteners for surface.

4.

Place operator

(motor)

end of

rear

shade into its bracket.

5.

Secure motor plate with the provided clips.

6.

Slide notched pin into idler bracket. Secure with retainer clip

and lock into place with rotating idler lock.

7.

Repeat with

front

shade.

Retainer

Clip

Retainer

Clip

OPERATOR

END

IDLER

END

Figure 1

page 3 of 12

Dual Roller Coupled Motorized FlexShades

®

(Large Hardware)