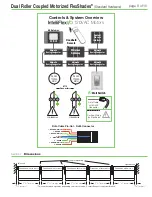

Section 3 -

Fascia Attachment

Section 2.5 - Final

(Idler-end)

Fabric/Roller Assembly

(Fig. 6)

1.

If desired, the proper location of the next bracket assembly can be verified.

Otherwise, proceed to Step 2.

2.

Install idler-end bracket/endcap assembly.

3.

Retract coupler shaft of previously installed roller to the intermediate position

(see "Operating the Retractable Shaft" and Fig. 2)

. The end of the coupler shaft should be flush

with the outside edge of the bearing.

4.

Lift both ends of the idler-end fabric/roller assembly into place and align between the

brackets/endcaps.

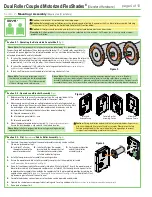

Section 2.4 - Intermediate Fabric/Roller Assembly

(Fig. 5)

Please Note:

Skip this section if your unit only has two panels

1.

If desired, the proper location of the next bracket can be verified. Otherwise, proceed to step 2.

2.

Install the next coupler bracket to mounting surface.

3.

The end of the previously-installed coupler shaft should be flush with the outside edge of the

bearing. If it is extended beyond the bearing, you can retract the coupler shaft of the previously

installed roller to the intermediate position

(see "Operating the Retractable Shaft" and Fig. 2)

.

4.

Lift both ends of the intermediate fabric/roller assembly into place and align between the rear/

upper brackets.

5.

Installer #1 fully extends coupler shaft of previously installed roller by rotating the metal ring clockwise about 180° when viewing the face of the coupler

assembly

(see "Operating the Retractable Shaft" and Fig. 2)

, until the shaft extends fully into the receiver of the fabric/roller assembly being installed.

6.

Installer #2 extends the coupler shaft of the fabric/roller assembly being installed to the intermediate position by rotating the ring clockwise about 120°

(see

"Operating the Retractable Shaft" and Fig. 2)

so the end of the shaft is flush with the outside edge of the bearing.

7.

Operate the shade to ensure proper fabric tracking.

8.

Lower the unit

(all shades will operate simultaneously)

to lower limit.

9.

If needed, the fabric panel heights can be adjusted so that the bottom edges of the fabric panels are aligned. On large units, this procedure should be done

on only one panel at a time to minimize the amount of fabric weight that must be supported during the adjustment procedure.

(See "Fabric/Roller Assembly Alignment” on page 6)

for instructions.

10.

Repeat steps above under "Second Fabric/Roller Assembly" for additional intermediate panels.

5.

Installer #1 places the idler-end sliding shaft onto the idler-end bracket

(Fig. 6)

. Lock shaft in place by placing retaining clip on shaft.

6.

Installer #2 fully extends coupler shaft of previously installed roller by rotating the metal ring clockwise about ½ of a turn when viewing the face of the

coupler assembly

(see "Operating the Retractable Shaft" and Fig. 2)

, until the shaft extends fully into the receiver of the idler-end fabric/roller assembly.

Caution:

Ensure shaft is locked in place with retaining clip on shaft.

7.

Operate the unit to ensure proper fabric tracking.

8.

Lower the unit

(all shades will operate simultaneously)

to lower limit.

9.

If needed, the fabric panel heights can be adjusted so that the bottom edges of the fabric panels are aligned.

On large units, this procedure should be

done on only one panel at a time to minimize the amount of fabric weight that must be supported during the adjustment procedure.

(See

"Fabric/Roller Assembly Alignment” on page 6 for instructions.)

10.

Repeat steps followed for rear/upper fabric/roller assemblies under First

(Operator-end)

Fabric/Roller Assembly, Second Fabric/Roller Assembly and Final

(Idler-end)

Fabric/Roller Assembly sections above for lower/front fabric/ roller assemblies.

1.

Place groove along top of fascia over endcaps, and snap into place

(Fig. 7)

. Fascia is not fully seated until it clicks into place on both ends. Once

in place, check for secure fit. If not secure, secure with appropriate fastener

(not included)

.

Figure 5

EXT

END

RETRAC

T

EXT

END

RETRAC

T

EXTEND

RET

RAC

T

EXTEND

RET

RAC

T

EXT

END

RETRAC

T

EXT

END

RETRAC

T

EXTEND

RET

RAC

T

EXTEND

RET

RAC

T

Figure 7

Figure 6

STEP 2

Clicks into place

STEP 1

page 5 of 10

Dual Roller Coupled Motorized FlexShades

®

(Standard Hardware)