Overview -

Components

Contents

Overview -

Components .......................................................................................1

PLEASE READ -

Important Safety and Installation Information ....................2

PLEASE READ -

Cleaning and Maintenance .....................................................2

Section 1 -

Site Preparation ................................................................................3

Section 2 -

Curved or Square Headbox Mounting ..........................................3

Section 3 -

Attaching Mounting Brackets to Headbox ...................................4

Section 4 -

Direct Mounting to Ceiling or Wall .................................................4

Section 5 -

Installing Side Channels ..................................................................5

Section 6 -

Mounting Angled Headbox ..............................................................6

Section 7 -

Mounting Headbox in a Recessed Pocket ....................................6

Section 8 -

Mounting Side Channels Into a Recessed Pocket ......................7

Section 9 -

Channel Adaptors .............................................................................7

Section 10 -

Anti-Insect Brush Seals .................................................................7

Section 11 -

Limit Setting: RTS Obstacle Detection Motors ..........................8

Section 12 -

Limit Setting: Standard and Quiet Motors ..................................9

Section 13 -

Complete Electrical Connection ..................................................9

Section 14 -

Cable Exit ........................................................................................10

Section 15 -

Hem Bar Liner ................................................................................10

Section 16 -

Assembled Dimensions: Front View ..........................................11

Section 17 -

Assembled Dimensions: Side View ............................................11

Section 18 -

Component Dimensions ..............................................................12

POWER DRILL

PENCIL

2

1

TAPE MEASURE

HARDWARE

(by others)

LEVEL

PLIERS

CRIMPING TOOL

WIRE STRIPPERS

CAUTION

Read and understand

all warnings before

beginning installation.

LASER LEVEL

HEX WRENCH

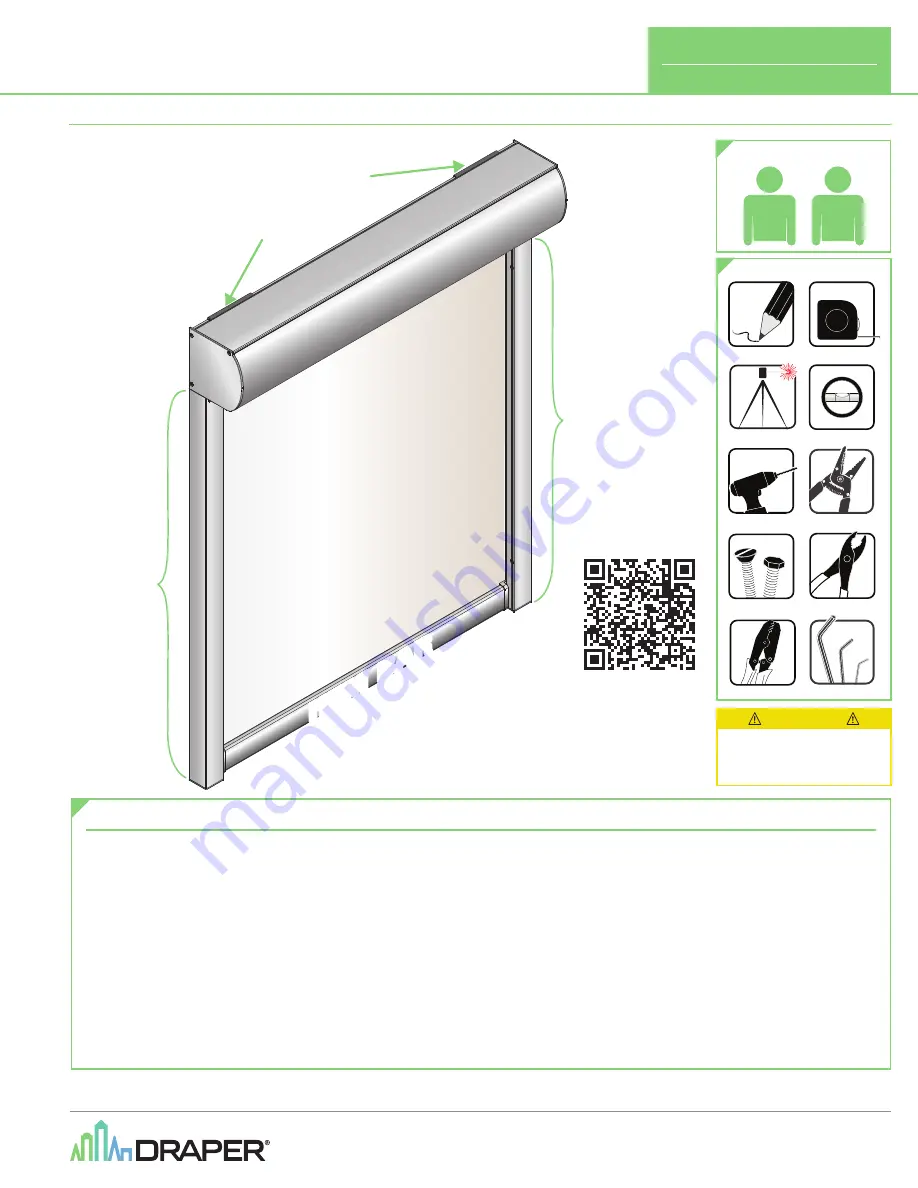

TOOLS REQUIRED

PERSONNEL REQUIRED

HEA

DBO

X

SHA

DE

FAB

RIC

MOUNTING

BRACKETS

(W

all M

oun

t sho

wn)

HE

M B

AR

END

CAP

SIDE

CHANNEL

SIDE

CHANNEL

Draper, Inc. | 411 S. Pearl St. Spiceland, IN 47385

draperinc.com | 765.987.7999 | 800.238.7999

© 2020 All Rights Reserved

|

FORM: FS_ZIP_Inst20

FlexShade

®

ZIP 92 & ZIP 127

Exterior shading system, ZIP detail creates weather/shading barrier

protects against wind, sun, snow, and insects to maintain a comfortable space

INSTRUCTIONS

INSTALLATION & OPERATION

If you have any difficulties installing or servicing your

FlexShade ZIP, call your dealer or Draper, Inc.

Scan code with your

smartphone to view a playlist

of FlexShade

®

ZIP installation

videos. These videos do not

replace the written instructions,

but offer valuable help.