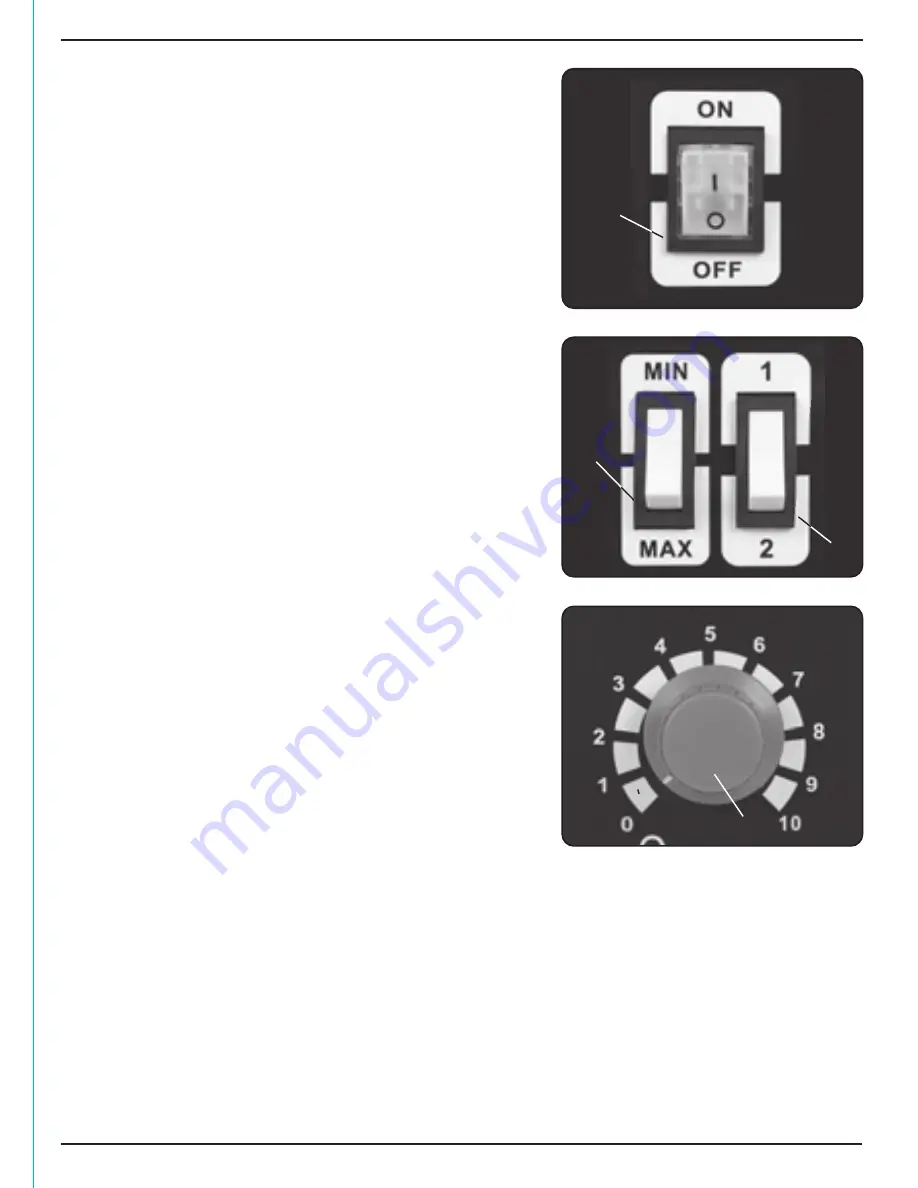

FIG.8

FIG.9

FIG.10

16

9. BASIC WELDING OPERATIONS

9.1 ON/OFF SWITCH – FIG.8

The on/off switch

is a rocker switch. Press the top

half in to switch the welder 'on' and the bottom half

in to switch the welder 'off'.

9.2 WELDING CURRENT REGULATION

SWITCHES – FIG.9

The current regulation switches

and

regulate

the welders power in four steps. Min +1, Min +2 and

Max +1, Max + 2. Regulate the welding current in

conjunction with the wire speed

to achieve the

optimum arc for the workpiece thickness and type.

9.3 WIRE SPEED ADJUSTMENT – FIG.10

Wire speed is dependent on material thickness and

welding current. Being able to judge the correct wire

speed based on the sound and quality of the weld will

only come from practice.

• Too fast will result in holes blowing in the weld

or the wire hitting the metal will force the torch

backward.

• Too slow will result in the wire burning back to

the torch into a ball and clogging the tip.

Note:

When using the welder on a low amp

setting/low wire speed, it is necessary that the wire

drive tension is increased on the adjustment to avoid

the spool stalling.

Summary of Contents for MIG100GG

Page 22: ...22 NOTES ...

Page 23: ...23 NOTES ...