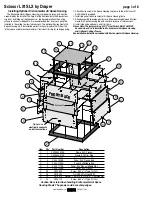

Installing Optional Ceiling Closure

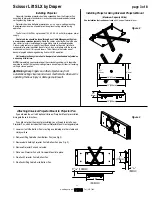

If your Scissor Lift SLX is equipped with optional ceiling closure, it can be used as is, or in conjunction with a square of existing ceiling tile (see Fig. 5)

.

1

If installing with ceiling tile, you may need to cut tile so that its overall dimensions

are the same as (or slightly less than) the closure panel. Place tile into trim frame.

Lay closure panel on top (back side) of ceiling tile, and tighten screws to hold in place.

Lipless Closure Option

is available by removing the Trim Ring from the

Closure Panel. A substrate material (ceiling tile, gypsum board, etc.) can be

attached directly to the Closure Panel using adhesive, double-sided tape or

screws.

NOTE: Make sure the added weight of the substrate does not

exceed the stated weight capacity of the lift.

Substrate should be installed

so that it is centered within the finished opening in the ceiling, with a gap of no

less that

3

/

16

" around all edges. Lipless Closure dimensions shown with

*

in

drawing below.

2

Attach provided angle brackets to side of Bottom Panel of Scissor Lift SLX.

3

Attach threaded rods to angle bracket.

4

Run unit “up” until bottom pan stops at highest position. Mark position on

rods even with ceiling level and cut to length (remove from pan if convenient).

5

Run unit “down” until bottom pan stops at “show” position.

6

Attach closure to lower end of rods by slipping into four corner slots and

secure with nuts above and below slots.

Caution: Make sure nuts are completely tightened.

7

Run unit “up” again to highest position. Measure distance by which panel fails to

reach required “closed” height for surrounding ceiling.

8

Run unit “down” then re-adjust mounting of threadedrods in traveling grid to raise

panel required distance.

9

Test unit operation to confirm that panel will stop in closed position just before

touching ceiling.

PLEASE NOTE:

Immediately upon completion of the surrounding ceiling, unit should be

operated to confirm that optional ceiling closure panel by Draper or by

others stops

1

/

8

" short of touching ceiling in closed position. If closure panel

touches, the motor may continue operating after the lift is closed.

If it continues to cycle once the lift is closed, a motor failure may occur.

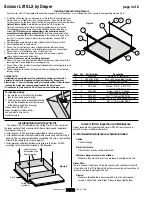

Installing Optional Ceiling Trim Kit

The Scissor Lift SLX is available with a Ceiling Trim Kit, which consists of

the lower section of the Environmental Air Space Housing and the optional

closure panel

(see Fig. 6).

1

Install Scissor Lift SLX as previously described in these instructions.

2

Install bottom section of Environmental Air Space Housing and Trim Ring in

opening. This can be accomplished by suspending with wire, or by mounting

directly to the ceiling joists (if space permits).

3

Install projector and attach optional ceiling closure to Scissor Lift SLX,

according to the instructions included in this document.

Ceiling tile

(by others)

Lower section of

Environmental Air

Space Housing

Trim Ring

Item Qty

Part number

Description

1

1

C028.546

Frame, SLX Closure Trim

2

1

C044.181.07SA

Panel, SLX Assembled Closure

3

2

C002.845.07SA

Bracket, SLX Closure

4

4 C077.035.49 Rod

3

/

8

"-16 x 17

7

/

8

" L Threaded , Zinc

5

8

C013.050

Washer .375 I.D. x .875" O.D.

x .064" TK GRD 2 Zinc Flat

6

8

C020.082

Screw, 10-16 X ½" 6 Lobe

Truss Head AB E-White

7

16 C018.027

Nut,

3

/

8

"-16 Hex GRD 2 NSF

8

4 C020.322 Screw,

5

/

16

"-18 x ¾" Long Grade 5 HH Zinc

9

4 C018.045

Nut,

5

/

16

"-18 Zinc Hex KEPS

1

2

3

8

9

7

4

7

5

6

Figure 5

Figure 6

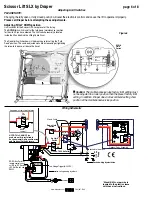

For Additional Safety:

1

Be sure the nuts that attach the threaded

rods to the closure panel are tight.

2

Wrap a plastic wire tie around the mounting

tab and the threaded rod at all four corners

of the closure panel (see drawing).

Please Note: Do NOT use a

paper-covered or similar wire tie—

use only plastic wire ties for

maximum safety.

Scissor Lift SLX by Draper

page 4 of 8

www.draperinc.com

(765) 987-7999

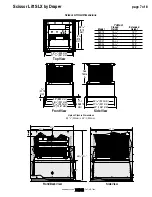

Scissor Lift SLX Inspection and Maintenance

Draper recommends inspecting the Scissor Lift SLX at least annually or

every 300 cycles—whichever comes first.

A recommended maintenance schedule includes:

-

Cables:

Check for fraying.

-

Drive Chain Gears:

Check for rust, breaks, secure attachment.

-

Fasteners along scissor arm assemblies:

Make sure they are not loose. If any are loose, hand tighten the nuts.

Please Note:

There is no need to tighten nut in the top scissor which slides back and forth

in the side slot in the lift. Tightening this fasteners assembly will cause the unit

to lock up and lead to damage to the unit.

-Closure:

Make sure threaded rod remains seated firmly in the closure panel

corners, and that nuts remain tight. If they are loose, tighten them.