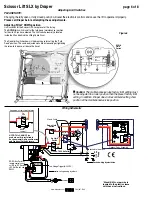

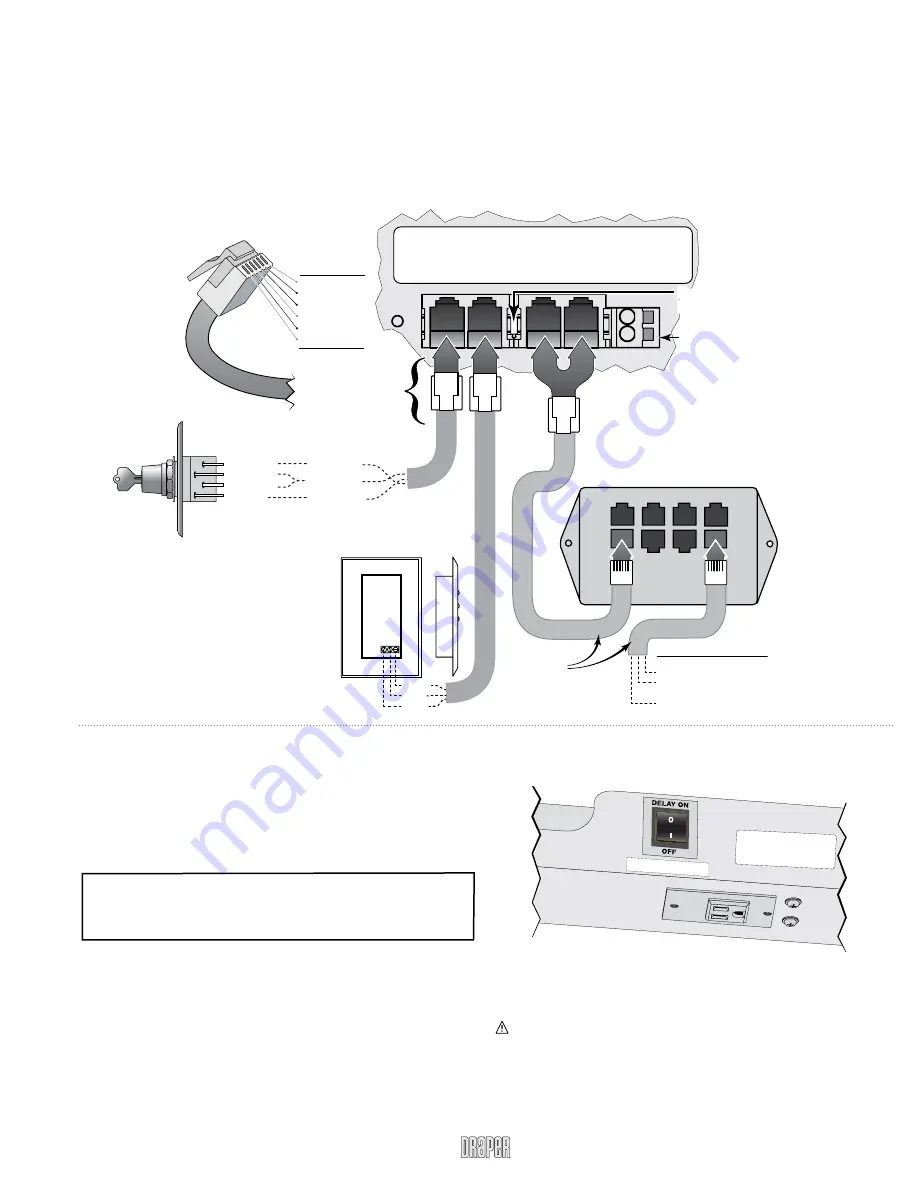

KEY

W

ALL

RP/RQ

RP/RQ

LV

T

Red - Down

Black - Com

Black - Com

Blue - Up

Pin 3 - Green

Pin 2 - Yellow

Pin 5 - Black

DCU

Green

Black

Yellow

PIN

1 -

NOT USED

2 - YELLOW

3 - GREEN

4 -

NOT USED

5 - BLACK

6 -

NOT USED

Please Note:

Data cable connections must

be made using

electrically

straight 6 Pin 4 conductor

modular cable

(RJ14/6P4C)

.

Please Note:

Data Cables

for Serial Control

Provided by Others

SP-KSM

Key Switch-

Service Position

Optional R2D7,

RS232 Controller

RP/RQ Bus Ports

for remote controls

such as

IR Eye, RF Receiver,

LED Wall Switch

and

RS232.

LVC-S

Show Position

Low Voltage Trigger

(6-24 VDC)

(Polarity Independent)

Function

Indicator

To RS232 Serial Port:

Blue = Not Used

Yellow = Rx

(Data from control system)

Green = Tx

(Data to control system)

Red = Not Used

Black = Gnd

(Signal Ground)

White = Not Used

DETAIL OF DATA CABLE

SPLITTER BOARD

Scissor Lift SLX by Draper

page 5 of 8

www.draperinc.com

(765) 987-7999

Connecting Controls to Data Cable Splitter Board

Controls plug into the

Data Cable Splitter Board

(See diagram below)

which is located on the Top Frame on the front side of the lift, using

RJ14/6P4C connectors

.

For IR or RF Remote Control

, use data cable with RJ14/6P4C connectors on both ends.

For serial control of "Show" position,

use data cable with RJ14/6P4C connectors on both ends and an R2D7 Serial Control Interface.

Plug into the "RP/RQ" input.

Figure 7

Clearing and Resetting Show Position

CLEARING THE SHOW POSITION AT CURRENT SHOW POSITION:

1

Move lift to the show position.

2

While lift is at the show position press and hold the Key Up toggle

switch and release once the Lift begins moving upward.

3

The show position is now cleared and ready for a new show position

to be set.

PROCEDURE FOR SETTING SHOW POSITION:

1

Now that the show position has been cleared, use wall switch up and down

buttons to get lift into desired show position.

2

While lift is at desired show position, press and hold the Key Down toggle

switch until lift begins to move upward. Lift will begin a calibration cycle

where it will move upward for two seconds, stop then move down for one

second and then the Lift will return to the desired show position.

PLEASE NOTE: At this point the Key Switch will not operate until

the new “Show Position” has been set. Also the 3-Button Wall Switch

changes into a maintain, push and hold type button, for continuous

movement. This allows for easy setting of new “Show Position”)

Optional Delay Feature

1

When the Optional Delay Feature is installed the Delay Switch must be in

the "Delay On" position for normal operation.

2

If the Optional Delay Feature is installed and the "Show Position" requires

adjusting, then the "Delay Switch" must be switched to

Off

while adjusting

the show position.

CAUTION:

Be sure all switches are in

Off

position before adjusting limit

switch. Always be prepared to shut lift off manually when new adjustment is

being tested. Please refer to wiring diagram.

PLEASE NOTE: If the Scissor Lift loses power, the

DOWn

function will not work until you operate the lift in the

UP

direction using the wall switch. This allows the lift's control

encoder to recognize it's "home" location.

NOTICE -

Delay Feature Will

Not Operate Properly Without

The Optional Current Sensor

Connected To The Lift.

KEEP DELAY IN OFF POSITION

WHEN

CURRENT SENSOR IS NO

T USED

Please Note:

Any control, including automated

dry contact systems, being

connected to the wall switch input

MUST send a momentary signal.