12

8

PREPARING THE ROUTER

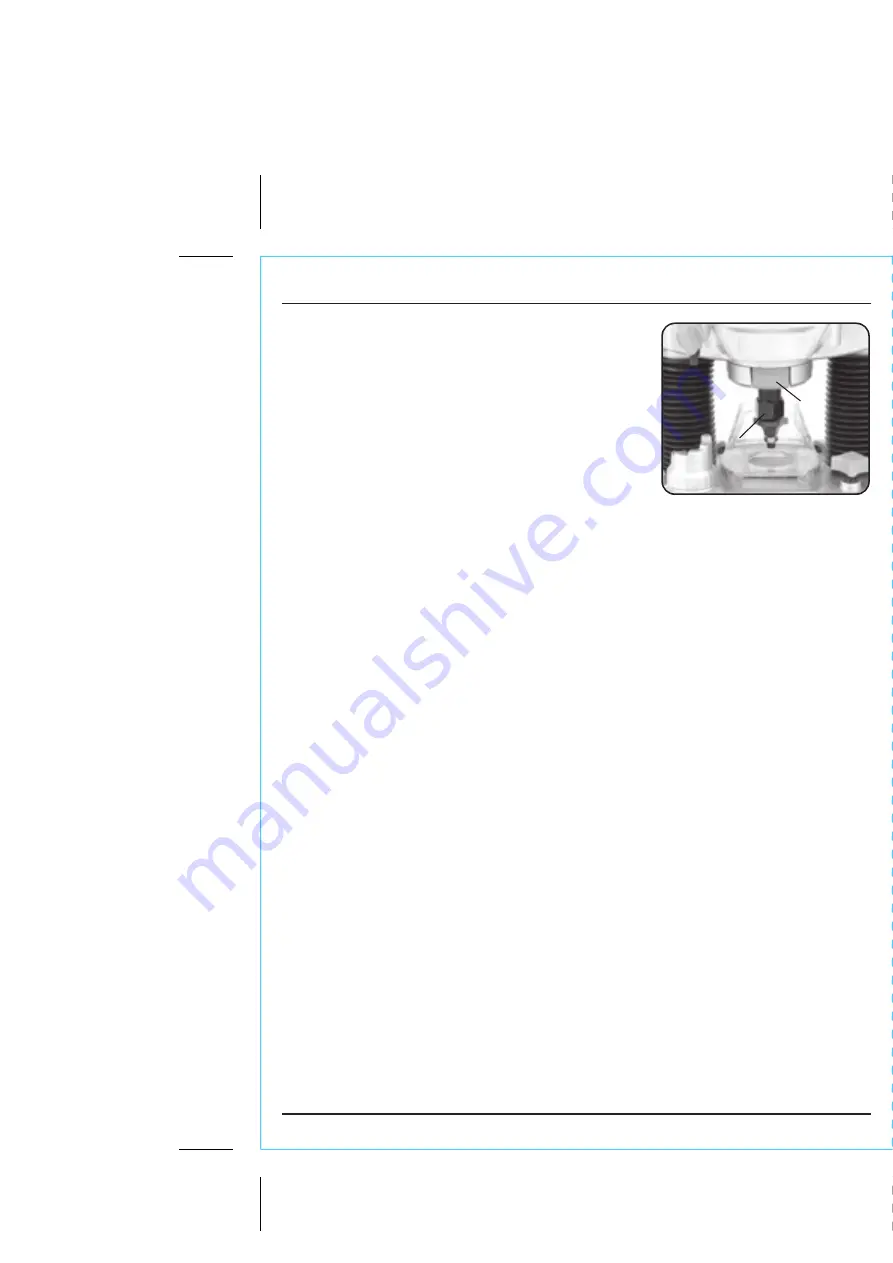

8.5 FITTING & REPLACING ROUTER BITS -

FIG. 4

This router is designed for use with ¼” and 8mm

shank router bits only.

WARNING: Use bits of the correct shank diameter

suitable for the speed of the tool.

Selection of the correct router bit, suitable for the

intended application is vital. Seek guidance if

uncertain of selection.

Press the spindle lock button

and unscrew the

collet nut

using the spanner supplied.

NOTE: Take care not to loose the spring behind the

collet.

Choose from the collets provided, the appropriate size

for the cutters shank (¼") 6.35mm or 8mm (

5

⁄

16

"). If the

size is not known insert the bit into the collet. The

collet which offers a machine fit to the shank is the

correct one to use. Do not force the bit into a collet.

Replace the spring and place the collet into the

spindle before loosely replacing the nut

.

Slide in the bit allowing approx. 5-10mm overhang

before tighten the collet nut (observe the router bit’s

manufacturers instructions for more specific

information).

NOTE: Ensure at least 75% of the shank is inside the

collet. Do not tighten the collet with no bit fitted as

this will cause damage.

Do not overtighten the collet nut.

WARNING: Take care when handling the cutter bits as

they are extremely sharp.

When cutting is complete remove the bit before

cleaning and storing it in a safe place.

FIG.4