5

6.

CONNECTING A HEATER TO A HOT WATER DISTRIBUTION

Implement the connection in accordance with scheme on page 6.

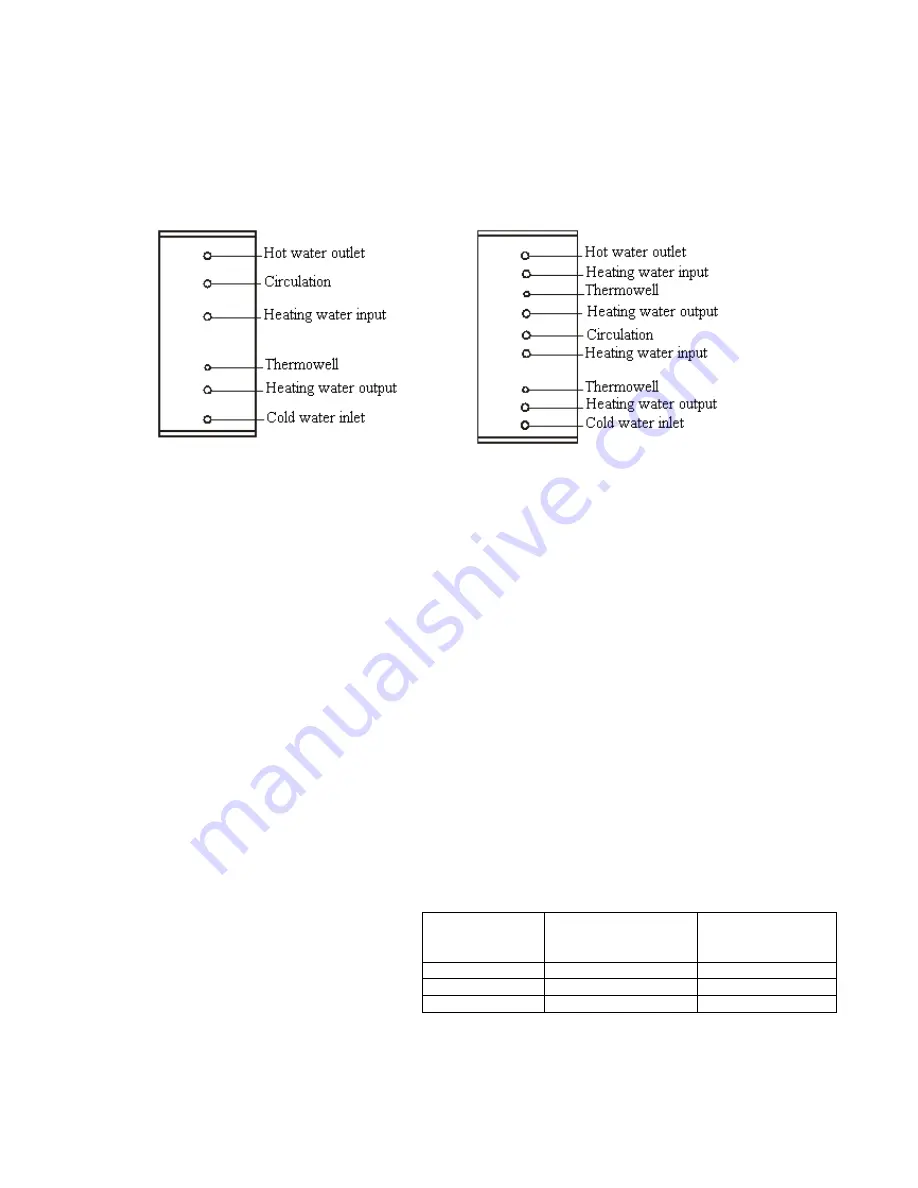

Scheme of Heater's Water Inputs and Outputs

OKC 800 NTR/1 MPa

OKC 800 NTRR/1 MPa

OKC 1500 NTR/1 MPa

OKC 1500 NTRR/1 MPa

OKC 2000 NTR/1 MPa

OKC 2000 NTRR/1 MPa

The heater’s cold water inlet must be fitted with a T-fitting with a discharge valve for any discharge of water from the

heater (see Section No.11).

On the hot water inlet, each individually closable heater must have a test cock, backflow valve, safety valve, and a

manometer.

7.

SECURITY EQUIPMENT

Each hot service water pressure heater must have a safety valve with a backflow flap. Nominal clearance of safety

valves is defined in the ČSN 06 0830 standard. The 300 l heaters are not equipped with a safety valve. The safety valve

must be easily accessible, as close to the heater as possible. The inlet pipes must have at least the same clearance as the

safety valve. The safety valve is placed high enough to secure dripping water drain by gravity. We recommend

mounting the safety valve onto the branch led above the heater. This allows easier exchange without having to drain the

water from the heater. Safety valves with fixed pressure settings from the manufacturer are used for the assembly.

Starting pressure of a safety valve must be identical to the maximum allowed heater pressure, and at least 20 % higher

than the maximum pressure in the water main. If the water main pressure exceeds such value, a reduction valve must be

added to the system.

No stop valves can be put between the heater and the safety valve. During the assembly, follow the

guide provided by the safety equipment manufacturer. Before putting the safety valve into operation it always needs to

be checked by manual removal of the membrane from the valve seat and turning the make-and-break device button

always in the direction of the arrow. After being turned, the button must click back into a notch. Proper function of the

make-and-break device results in water draining through the safety valve outlet pipe. In common operation, such a

check needs to be implemented at least once a month, and after each heater shutdown for more than 5 days. Water can

drip from the safety valve through the drain pipe; the pipe must be freely open to the atmosphere, placed vertically and

shall be in an environment free of temperatures below freezing.

When draining the heater, use a recommended drain

valve. First, close water input into the heater.

Find necessary pressure values in the following table.

For proper safety valve operation, a backflow valve

must be mounted on the inlet pipes, preventing

spontaneous heater draining and hot water

penetrating back into the water main.

When assembling the security equipment, follow ČSN 06 0830.

Safety valve

starting pressure

(MPa)

Admissible operating

water heater

pressure (MPa)

Max. pressure in

the cold water pipe

(MPa)

0.6

0.6

up to 0.48

0.7

0.7

up to 0.56

1

1

up to 0.8