8

12.

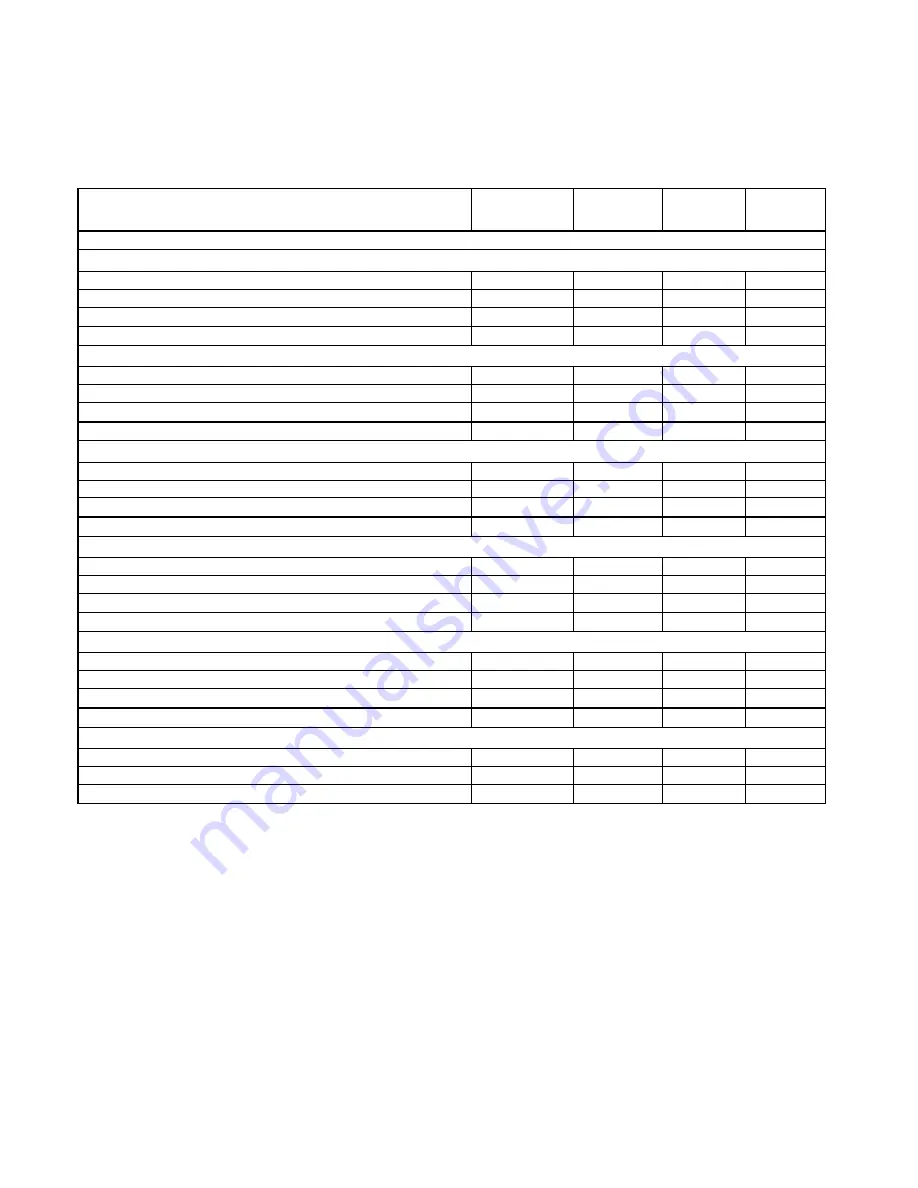

PERFORMANCE DATA

Exchanger performance the for flow of

500 l/hr

1,000 l/hr

3,000 l/hr

4,500 l/hr

800 NTR/NTRR – bottom exchanger surface 2.76 m

2

Heating time by exchanger for temperature drop 80/60°C (min)

136

94

66

61

Performance for temperature drop 80/60°C (kW)

20,2

29,9

41,8

45

Permanent performance (l/hr)

348

515

720

775

800 NTRR – top exchanger surface 1.2 m

2

Heating time by exchanger for temperature drop 80/60°C (min)

81

60

46

42

Performance for temperature drop 80/60°C (kW)

14,4

19,2

24,6

26

Permanent performance (l/hr)

248

330

423

447

1500 NTR/NTRR – bottom exchanger surface 3.5 m

2

Heating time by exchanger for temperature drop 80/60°C (min)

213

128

71

60

Performance for temperature drop 80/60°C (kW)

25,2

38,9

64,4

74,2

Permanent performance (l/hr)

435

670

1109

1276

1500 NTRR – top exchanger surface 1.75 m

2

Heating time by exchanger for temperature drop 80/60°C (min)

137

94

63

56

Performance for temperature drop 80/60°C (kW)

19,4

26,4

37,2

40,9

Permanent performance (l/hr)

334

454

640

704

2000 NTR/NTRR – bottom exchanger surface 4.00 m

2

Heating time by exchanger for temperature drop 80/60°C (min)

262

155

86

73

Performance for temperature drop 80/60°C (kW)

28,9

44,2

71,5

81,4

Permanent performance (l/hr)

498

761

1230

1400

2000 NTRR – top exchanger surface 2.00 m

2

Heating time by exchanger for temperature drop 80/60°C (min)

160

108

70

63

Performance for temperature drop 80/60°C (kW)

21,2

29,2

41,9

46,3

Permanent performance (l/hr)

364

503

721

797

NL Power Factor

Based on DIN, the expression of a normal flat is introduced for apartment houses in the FRG. Such a flat has four rooms; it is

occupied by 3.5 people; it has a bathtub, a hand basin, and a sink. Flats of other sizes, number of occupants and different equipment

are converted to normal flats using the relations given in the standard (NL). The situation in our apartment houses, massively built

until the recent past, is similar. Flats intended for 3 to 4 people are equipped identically with normal German flats. Smaller flats tend

to have smaller bathtub or a shower; larger, so-called two-generation flats tend to have an extra hand basin. Apartment buildings

with luxury flats and high standard equipment, with higher number of fittings, of fittings equipped with high standard drain

armatures, both hot water and heat energy needs must be adjusted.