2 |Dresser Natural Gas Solutions

WARNING

PPE

Approved Personnel Protective

Equipment for the site must

be worn.

CAUTION

BURN HAZARD

Possible hot surface. Keep hands

clear of surface. Allow surface

to cool before performing any

maintenance.

WARNING

MOVING PARTS

Internal moving parts. Pinch point

hazard. Keep hands clear during

operation.

CAUTION

SERVICE PERSONEL

Service operators must be licensed/trained and authorized before

being allowed to perform maintenance on the actuator.

CAUTION

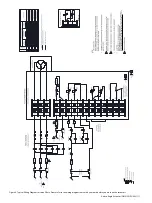

VOLTAGE SUPPLY

Verify that the supply voltage to the actuator matches the voltage

on the nameplate (33) on the gear compartment cover (21).

1.0 Storage Requirements

1. Actuators should always be stored in a clean dry

environment, in a location where mechanical damage

to the actuator can’t accidentally occur.

2. All covers must remain in place and securely fastened.

3. All pipe plugs must remain in place and be kept tight.

4. Actuators equipped with controllers can be damaged by

excessive moisture. Units so equipped should be stored in

a controlled environment prior to installation. If the units

are equipped with compartment heaters, the heaters must

be continuously energized while in storage.

2.0 Lifting Instructions

1. Do not lift Eagle actuator by limit switch compartment.

2. Follow applicable safety guidelines when lifting or moving

actuator.

3.0 Installation Requirements

While it is possible to mount the actuator in any position, it is not

recommended that the control compartment cover be positioned

face down. In order to maximize seal integrity, the unit should be

mounted with the extension rod pointed up (vertical installations)

or with motor on top (horizontal installations).

NOTICE

1. The body tube adapter (57) is used for face flange or

trunnion-type mounting.

2. The actuator can be clevis-mounted utilizing the clevis (29) in

the extension rod (6) and the rear clevis bracket, located on

the gear compartment cover (21).

Refer to Figure 1 on page 7.

Bien qu'il soit possible d'installer l'actionneur, on ne recommande

pas que le couvercle du compartiment de commande soit

positionné face vers le bas. Afin de maximiser l'étanchéité du joint,

l'unité doit être installée avec sa tige d'extension orientée vers

le haut (installations verticales) ou avec le moteur sur le dessus

(installations horizontales).

AVIS

AVERTISSEMENT

EPI

Il convient de porter un

équipement de protection

individuelle sur le site.

ATTENTION

RISQUE DE BRÛLURE

La surface risque de devenir

chaude. Éloignez vos mains de la

surface. Laissez refroidir la surface

avant les travaux de maintenance.

AVERTISSEMENT

PIÈCES MOBILES

Pièces mobiles internes.

Risque de point de pincement.

Tenez vos mains éloignées

pendant le fonctionnement.

ATTENTION

PERSONNEL DE MAINTENANCE

Les opérateurs de maintenance doivent être licenciés/formés et

agréés avant de pouvoir effectuer des travaux de maintenance sur

l’actionneur.

ATTENTION

SOURCE DE TENSION

Vérifiez que la source de tension de l’actionneur correspond à la

tension indiquée sur la plaque signalétique (33) du couvercle du

compartiment pour l’engrenage (21).