Instruction ES2007 4/98

Models 4700P and 4700E

18

Calibration

Warning: Before commencing any calibration or

maintenance procedure on these positioners, en-

sure that the valves under control are isolated

from the controlled process and that the area is

verified as nonhazardous.

General

The Model 4700P and 4700E positioner, when factory

mounted, has been calibrated for the proper valve, valve

action, and positioner action. If, for any reason, the cam

holder (36) setting has been disturbed (i.e., a change of

positioner action, field mounting, maintenance, etc.), it is

necessary to follow all steps of the calibration instructions,

according to desired actuator action and positioner action.

Calibration may entail just a simple adjustment or a com-

plete field mount. Define the scope of work and follow the

applicable sections.

Caution: Do not attempt to remove cam if cam is

not at low signal line of lobe (low end of range).

Refer to calibration instruction for proper valve

action and positioner action before removing or

replacing cam and tightening set screws (35) to

proper torque.

Zero Adjustment (Figure 19 & 20)

The zero adjustment is made with the zero nut (4B). When

the positioner is installed and the pneumatic circuits are

connected apply low instrument signal (i.e., 3 psi for 4700P,

4 mA for 4700E), release locknut (4C) and turn zero nut (4B)

to adjust valve plug to proper position (open or closed). Then

tighten zero lock nut (4C).

Note: Do not attempt to adjust zero nut with signal

above low end of signal range. If valve is seated at low

Mounting Cam Coupling

(Figure 19 & 20)

The cam coupling (34), used on rotary actuators, is posi-

tioned on the shaft with the key engaged in the shaft slot

and the set screws (35) to the top and side. The coupling

hold-down screw (32) with the lockwasher (33) is torqued

to 125 inch-lbs.

Mounting Cam

The cam holder (36) and cam (26) are positioned on the

cam coupling (34) so that the desired cam lobe’s low signal

line is properly adjusted on the cam follower (4A). Proper

adjustment is achieved when:

1. The desired cam lobe’s low signal line is in alignment with

the “raised reference line” on the positioner (Figure 19).

2. The cam is centered between the two arms of the cam

lever S/A (3) (Figure 19).

Changing Lever S/A Orientation

(see pages 27 - 29)

If lever S/A (3) must be changed, remove screw (28)

and washer (27), and cam (26) from cam shaft. Remove

retaining ring (17) and flat washer (16). Remove lever S/A

(3) from pivot post. Lift and rotate lever S/A (3) on spring

end 180

°

to desired position. (Do not rotate spring end;

socket head screw on spring must face outward.) Replace

flat washer (16) and retaining ring (17) on pivot post.

Lever S/A Orientation (see pages 27 - 29)

The relative position of the lever S/A (3) for a selected cam

lobe must be correct. The lever S/A can be mounted with its

pivot post to the left or right of the cam center.

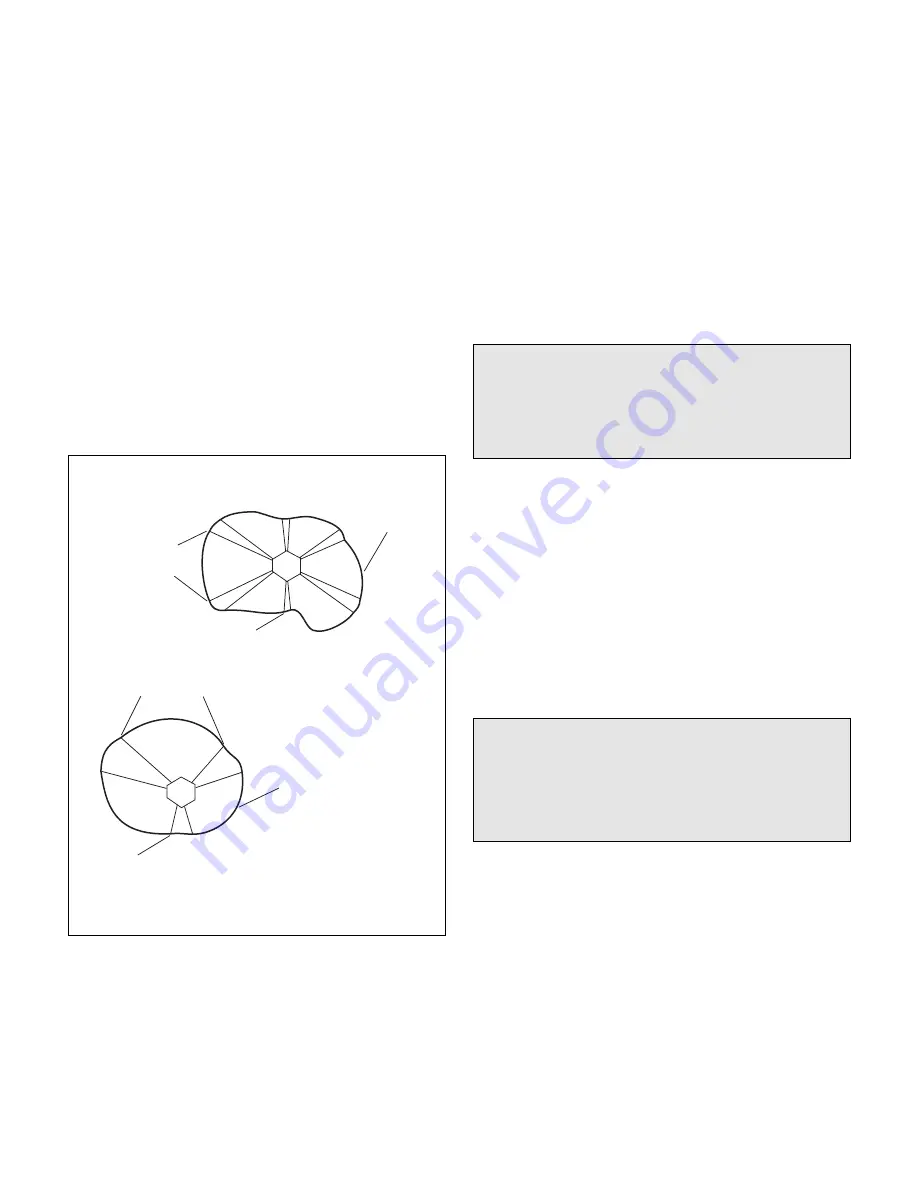

Lobe Identification

Figure 17

1

2

3

4

5

6

Lobe

(Lobe 3)

Low Signal Line

(Lobe 1)

Low Signal Line

(Lobe 1)

Lobe

(Lobe 3)

Lobe Lines

(Lobe 6)

Lobe Lines

(Lobe 2)

90

°

1

2

3

Note: The low signal line is the shortest

lobe line defining a particular lobe.

Summary of Contents for Masoneilan 4700E

Page 15: ...15 Instruction ES2007 4 98 Models 4700P and 4700E Figure 14 FM Installation ...

Page 16: ...Instruction ES2007 4 98 Models 4700P and 4700E 16 Figure 15 CSA Installation ...

Page 17: ...17 Instruction ES2007 4 98 Models 4700P and 4700E Figure 16 CENELEC Installation ...

Page 32: ...Instruction ES2007 4 98 Models 4700P and 4700E 32 Figure 20 4700E Rotary Reciprocating ...