Flowgrid Slam Shut | 13

Maintenance of the Shut-off Valve

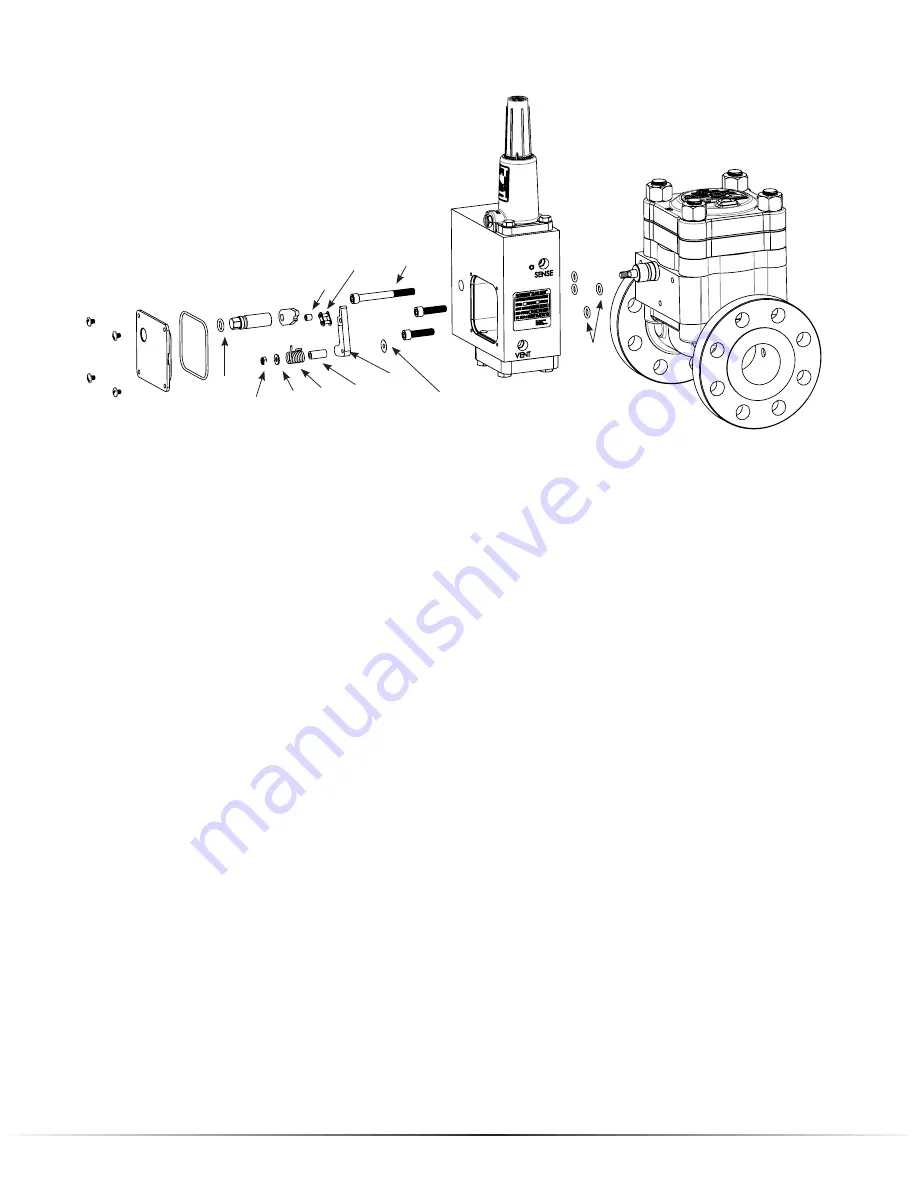

Controller Removal from the Shut-off Valve

1. Remove the sense line from the controller.

2. Remove the cover off of the latch cavity. Remove the

cover o-ring and discard.

3. If the shut off valve (flapper valve) is open using a screw

driver, lift up the short leg of the pawl lever causing the

valve to close.

4. Remove the locknut, washer, spring, spacer and pawl

lever.

5. Remove the front reset nut holding the flapper lever on

the flapper shaft. NOTE: The threads on the nut are left

hand. Discard the o-ring on the front reset nut.

6. With a ¼ inch hex wrench remove the three cap screws

holding the controller and latch module to the shut off

valve body.

7. The flapper lever is press fit on the shaft making removal

difficult. The lever is easily pulled off by using the control-

ler housing to drive it off the shaft. Grab the controller on

each side and rapidly pull the housing so it drives the lever

off. If necessary repeat the action.

8. Remove and discard the o-rings from the mating face of

the slam shut body, bushing and the controller and latch

module.

Locknut

Flapper

Lever

Screw

Controller

Assembly

O-Ring

Master

Link

Roller

Lever

Screw

Valve

Assembly

O-Ring

Washer

Spacer

Screw

Cover

O-Ring

Washer

Front Reset

Nut

O-Ring

Lever

Spring

2” Large Port

Flowgrid Slam Shut

Shown

Figure 9 - Controller Installation and Removal