16

|

Dresser Roots

Maintenance/Replacements

A good program of inspection and maintenance servicing, if

followed consistently, is the most reliable means of prevent-

ing costly repairs to a blower. A simple record of procedures

and dates will help maintain this work on a regular schedule.

Basic requirements are lubrication and cleaning, along with

periodic checking for increased vibration and hot spots on

the cylinder. Inlet and discharge pressures and temperatures

should be observed frequently, to minimize the chances for

trouble resulting from blower ratings being exceeded.

Above

all, the unit must be operated within its specifications.

In a blower properly installed and operated, there is no

moving contact between the two impellers, or between the

impellers and cylinder or headplates. Wear is then confined

to the timing gears, the bearings which support and locate

the shafts, and shaft seals. All are lubricated, and wear

should be normal if they are always supplied with clean, high

grade lubricating oil. Shaft seals, weather lip type or rotating

mechanical type, are subject to deterioration as well as wear.

They may require replacement at varying periods. O-rings

should be replaced at each disassembly.

If trouble should occur during operation, and its cause cannot

be readily determined, consult the TROUBLESHOOTING

CHECKLIST. Remedies suggested there can usually be

performed by qualified mechanics, using procedures detailed

in this manual. Major repairs not covered here are considered

beyond the scope of maintenance, and should be referred

to the nearest Sales Office. See listing on the last page.

Warranty failures

should not be repaired at all, unless

specific approval has been obtained through a Sales Office

before starting the work. Unauthorized disassembly within the

warranty period may void the warranty.

Where repairs involve parts replacement, it is recommended

that Factory Parts be used to insure fit and suitability. Delay

in making such repairs can be reduced by having spare parts

on hand.

When ordering parts, please furnish all information from the

blower nameplate.

Repairs or adjustments to blowers should be performed by

personnel with a good background of general mechanical

experience and the ability to follow the detailed instructions

in this manual. Some operations involve extra care and a

degree of precision work. This is especially true in timing

impellers, and in handling bearings. Experience indicates

that a high percentage of bearing failure is caused by dirt

contamination before or during assembly. Therefore, clean

the work area before starting disassembly, and protect new

or reusable parts during progress of the work.

The following detailed work procedures cover repairs and

adjustments that can normally be handled successfully at the

installation site. Numbers shown in brackets ( ) correspond

to Item Numbers used in the sectional assembly drawings

and in Table 9. Refer to the drawing applying to the type unit

being repaired while reading the instructions.

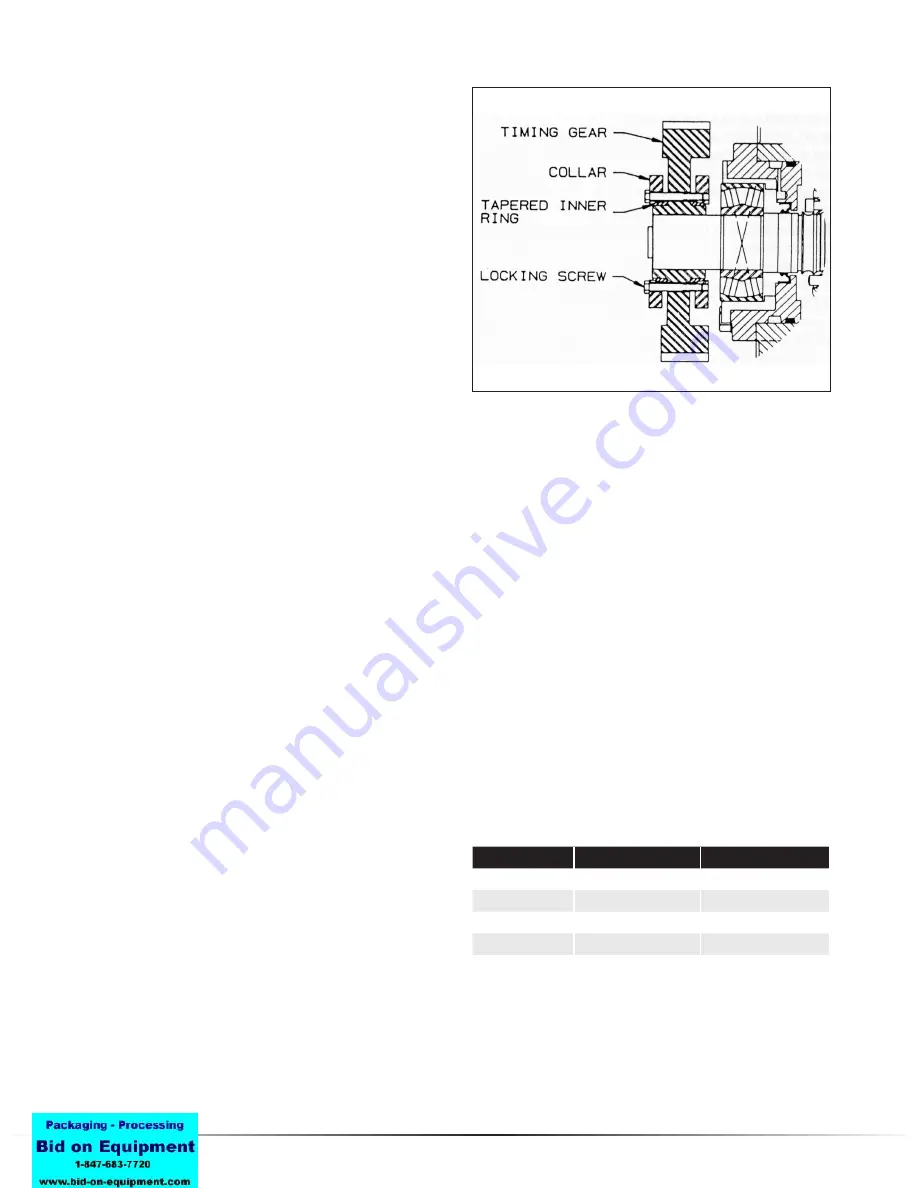

A - REMOVING GEARS WITH GEAR LOCKING

ASSEMBLIES

1. Drain oil at plug (67) near bottom of gearbox (3).

2. Loosen cap screws (30) attaching gearbox to headplate

3. Attach lifting device to support gearbox and remove

capscrews. Move gearbox out of way.

4. Match mark gears so that they can be returned to the

same shafts in same position.

5. Gradually release gear locking assembly capscrews

evenly all round. Initially each screw should be released

about a quarter of a turn only to prevent tilting and jam-

ming of collars. DO NOT REMOVE LOCKING SCREWS

COMPLETELY OR THE COLLAR MAY SPRING OFF

CAUSING INJURY. Just loosen the locking assembly,

both collars should be loose on the tapered inner rings.

To loosen the back collar, tapping on the locking screws

may be necessary. To loosen the front collar, use of

wedges between the collar and the gear web may be

required

6. Using two puller holes in the gear (see Table 6 for size)

pull the gears off the shafts,

B - INSTALLING GEARS WITH GEAR LOCKING

ASSEMBLIES

1. Apply NEVERSEEZ paste on the gear locking device

screw threads, under the screw heads, on the tapered

rings, on the collar tapers, and on the gear hub outside

diameters.

Figure 6 - Gear Locking Assembly

Table 6 - Puller Hole Sizes

Blower Size

Gear Puller Hole Size Carrier Puller Hole Size

1000

1/2/13

5/8/11

1200

3/4/10

5/8/11

1400, 1600

8-Jan

3/4/10

1800, 2000

1-1/4 - 7

8-Jan

Summary of Contents for Roots DVJ WHISPAIR

Page 22: ...DVJ WHISPAIR Dry Exhauster 23 Figure 15 Assembly of 10 thru 12 DVJ V V Belt Drive Splash Lube ...

Page 23: ...24 Dresser Roots Figure 16 Sectional Assembly of 10 thru 14 DVJ V Blowers ...

Page 24: ...DVJ WHISPAIR Dry Exhauster 25 Figure 17 Sectional Assembly of 16 20 DVJ Common Lube ...

Page 25: ...26 Dresser Roots Figure 18 Sectional Assembly of 1016 DVJ V Units ...