20

|

Dresser Roots

On a belt-drive unit with extended shaft, use spacer

sleeve (62) to push inboard bearing (60) into its final

position. There is no shaft shoulder behind this bearing,

but there is a stop for the sleeve. Make sure that the

inner race flange of bearing (60) is facing outboard.

2. Install bearing lockwasher (25) and locknuts (24) on each

shaft, and tighten nuts with a spanner wrench. Lock the

nuts by bending a tab on each washer into a slot in the

nut.

3. Install new or original gears and set impellers as

described in Operation B.

4. Place bearing clamp plate (8) over main bearing (31)

and tighten all screws. In the case of the extended type

drive shaft, end cover (58) serves as the clamp plate but

cannot be installed until later.

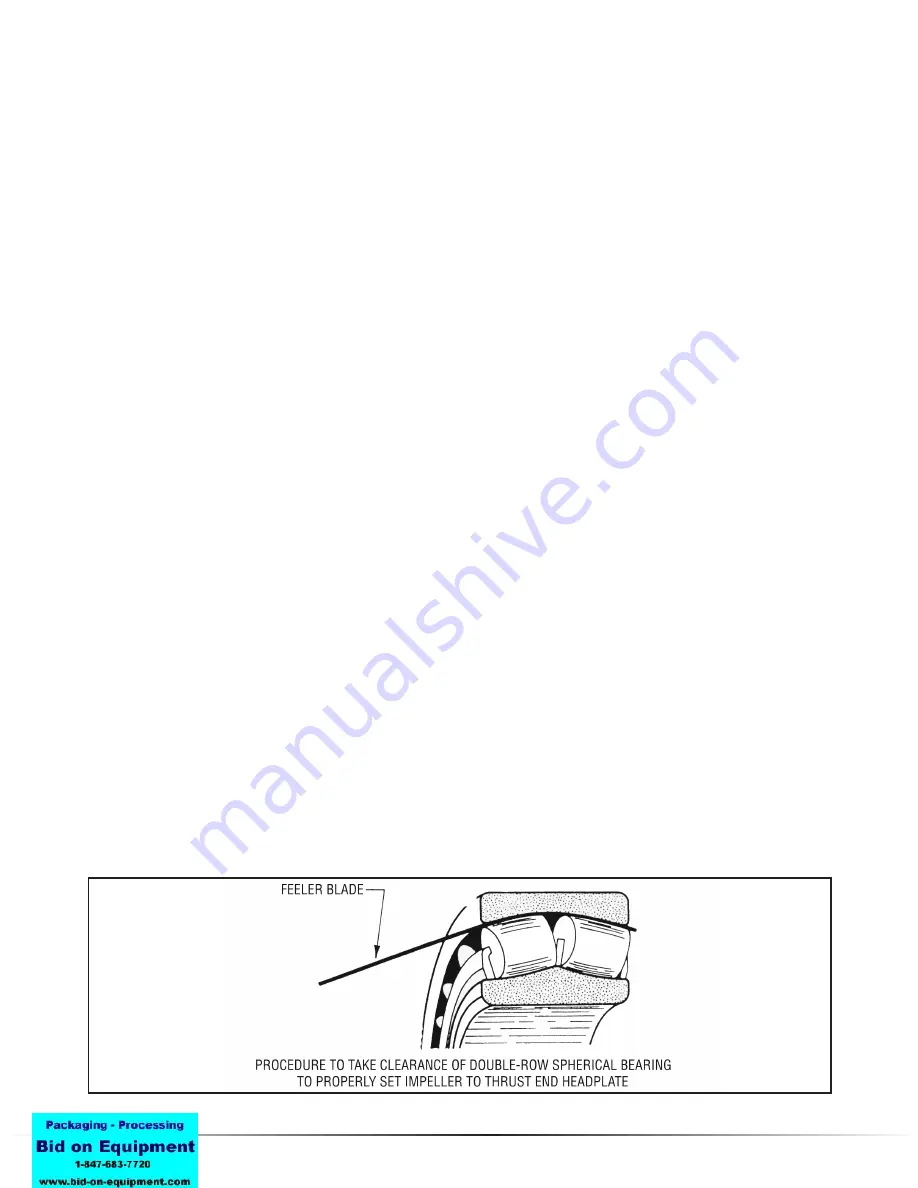

5. Using 1/2” (13mm) feeler gauges, determine for each

of the drive end bearings (31) the maximum clearance

between the outer race and one of the rollers near the

top. Obtain pieces of brass shim stock, of thicknesses

corresponding to these clearances, about 3/4” (19mm)

wide and long enough to reach completely through the

bearings. Push one piece through each bearing, in the

spaces between rollers, then rotate that shaft so that one

roller of each row is up on the shim stock. This removes

all clearances, and forces the bearing rollers and races to

center as in normal running. Refer to Figure 14.

6. Set the impellers lengthwise in the case by using long

pieces of shim stock, or feelers, as wedges between the

two ends of each impeller and the headplates. Using the

total end clearance obtained in Step 8 of Operation D,

the two ends of each impeller and the headplates. Using

the total end clearance obtained in Step 8 of Operation

D, place wedges equal to two-thirds of the total at the

gear end and one-third at the drive or thrust end. It will

be necessary to bump the shafts to obtain the required

impeller positions. Set the drive end clearance first, after

installing and tightening drive shaft end cover (58) if used.

7. With feeler gauges, carefully measure the spaces

between the drive end bearing carrier flanges and the

headplate face. Insert shims (17) of correct thickness to

fill these spaces. The original shims should be correct if

bearings and carriers have been returned to the original

location.

8. Remove wedges from ends of impellers inside the casing.

9. Tighten all bearing carrier flange screws.

10. Recheck impeller end clearances for proper values

per tables, then remove brass shim stock from both

bearings (31).

11. Check front and back clearances of impeller lobes as

outlined in Operation C, and reset timing if not correct.

12. Reassemble the unit, starting by installing the main end

cover (5) and then proceeding in reverse order through

Operation A from Step 5. Be careful with lip seal (23) or

new O-ring (59) in end cover (5).

13. Check the work area to make sure no parts have been

left out in assembly.

14. Turn the drive shaft over several times by hand as final

check for impeller contact or case rubs.

15. Reinstall coupling or belt sheave, check their alignment

with driver and reconnect all external piping.

16. Start and operate unit for a reasonable period in the

manner outlined for initial starting. See OPERATION.

IMPELLER CLEARANCES

Instructions on impeller clearances under Operation C and

Operation D do not include data on the amount of clearance

to be expected. For blowers in good condition this informa-

tion is not essential in field service work. However, situations

may arise where it is desirable to compare existing clearances

with the correct values. Listed in Table 8 or 9 are the ranges

of values used in original factory assembly. Clearances may

change in service, but they should never be less than the

minimum values listed. Only well

qualified personnel

should

attempt to measure clearances for comparison with this data.

Figure 14

Summary of Contents for Roots DVJ WHISPAIR

Page 22: ...DVJ WHISPAIR Dry Exhauster 23 Figure 15 Assembly of 10 thru 12 DVJ V V Belt Drive Splash Lube ...

Page 23: ...24 Dresser Roots Figure 16 Sectional Assembly of 10 thru 14 DVJ V Blowers ...

Page 24: ...DVJ WHISPAIR Dry Exhauster 25 Figure 17 Sectional Assembly of 16 20 DVJ Common Lube ...

Page 25: ...26 Dresser Roots Figure 18 Sectional Assembly of 1016 DVJ V Units ...