Surepowr Series

Sure 150

Installation Manual

Table of Contents

Intended of Usage ................................................................... 2

Actuator Range of Application ........................................... 2

1. Actuator Marking .....................................................3

2. Special Conditions for Safe Use

(ATEX)/Conditions of Certification (IECEx) ............3

3. Ratings ......................................................................3

4. Safety ........................................................................4

Safety First! ........................................................................................... 4

Warnings and Notices ...................................................................... 4

Joint Handling .................................................................................... 4

Fasteners ............................................................................................... 5

Seals ........................................................................................................ 5

Cable Glands ....................................................................................... 5

Grounding and Bonding ................................................................ 5

Spring Housing................................................................................... 5

Enclosure Surface Temperature ................................................... 5

5. Installation................................................................6

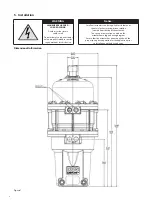

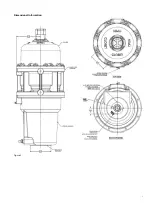

Dimensional Information ............................................................... 6

Dimensional Information ............................................................... 7

Cover Removal and Assembly ...................................................... 8

Mounting .............................................................................................. 8

Horizontal Mounting .............................................................. 8

Conduit Locations and Thread Sizes .......................................... 9

Cable Glands ....................................................................................... 9

Grounding and Bonding ................................................................ 9

Wiring ..................................................................................................... 9

Wiring Diagrams ....................................................................... 9

Mechanical Stop Settings ............................................................11

Limit Switch Settings .....................................................................11

Switch adjustments for clockwise spring fail

operation (viewed from the top of the actuator) ......11

Switch adjustments for counter-clockwise spring fail

operation (viewed from the top of the actuator) ......11

Limit Switch Settings (Optional Offering) .............................12

Installation.................................................................................12

6. Operation............................................................... 13

Thermal Overload ...........................................................................13

Duty Cycle ..........................................................................................13

Optional Manual Override ...........................................................13

7. Maintenance .......................................................... 13

Mounting Fasteners .......................................................................13

Enclosure Cover Screws ................................................................13

Seals and Cable Glands .................................................................14

8. Storage ................................................................... 14

RCS Actuators