SECTION 5

MAINTENANCE

Page 6

OM515C520C99/1E

DRESSTA

SCHEDULED MAINTENANCE GUIDE

Every 2000 Hours of Operation or every year (per Engine Operation Manual)

1. Perform the service as specified in "Every 1000 hours of operation"

2. Change the brake fluid. Refer to 5.7.3.

3. Clean the cooling system and change coolant. Refer to 5.8.5, 5.8.6., 5.8.7.

4. Check the condition of the muffler. Refer to Engine Operation Manual.

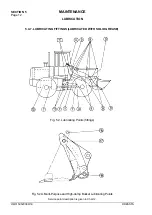

5.2.1. GROUND LEVEL INSPECTION

1. Loader Equipment: condition, efficiency.

2. Radiator: condition, evidence of leakage and condition of the grill (rod or sand - if equipped).

3. Hydraulic components: condition, leakage, operation.

4. Drive train: condition, leakage, noise, clearance.

5. Wheels: condition of tires, tire mounting on wheel rims.

6. Engine compartment: fuel, air intake, exhaust, lubrication and cooling system for leaks.

7. Control panels: check the condition and operation of instruments, gauges and warning lights.

8. ROPS: the condition of ROPS cab, operator’s seat with seat belt, access openings.

No defects of ROPS structure are permissible that may adversely affect its protection in case of

machine rollover.

9. Visually check the screw joints, particularly:

•

Drive axle to frame mounting,

•

Driveshaft connecting,

•

Center articulation pivot mounting,

•

Wheel mounting,

•

Cab to frame mounting.

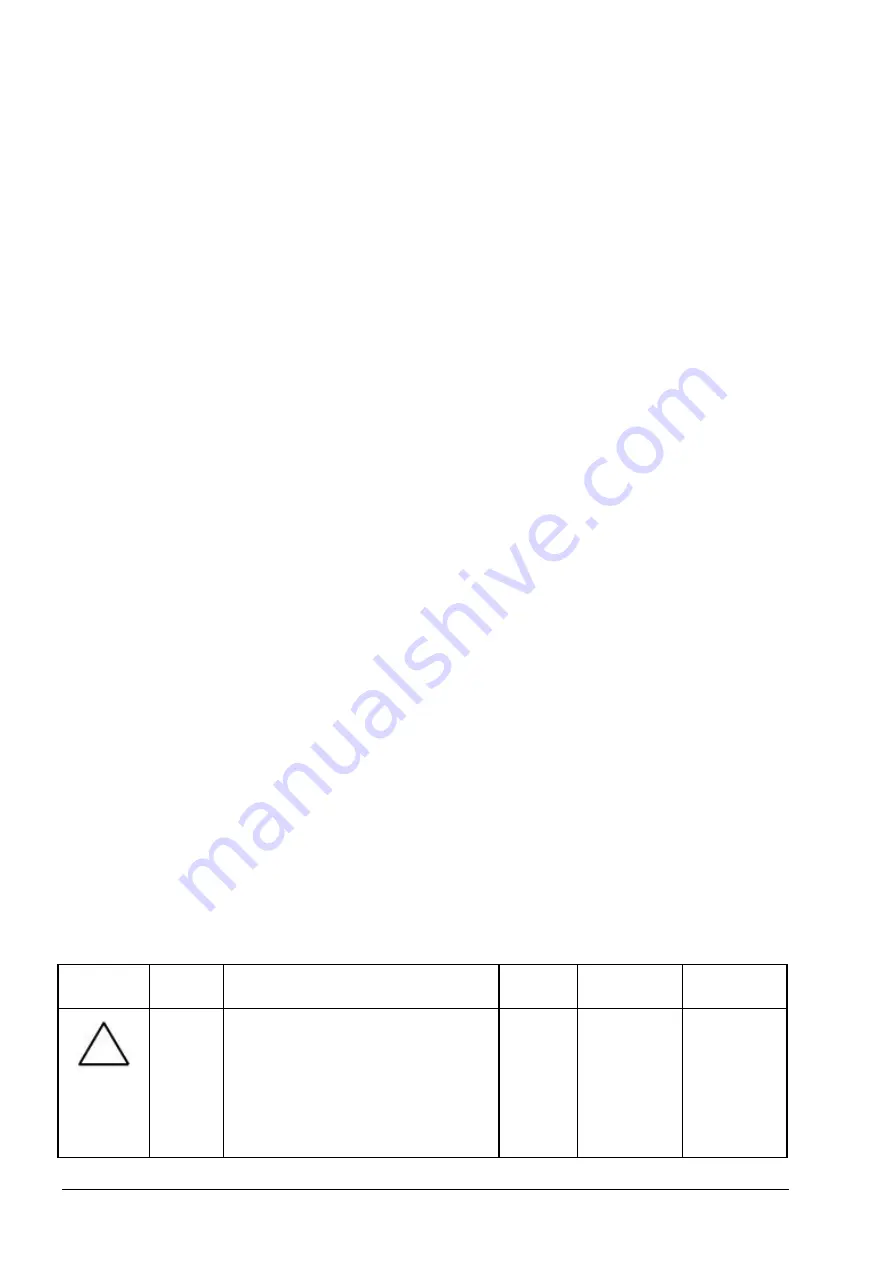

5.3. MAINTENACE AND SERVICE CHART

IMPORTANT:

The

points of service are individually explained in more details in the following text.

Always use clean lubricators and containers. Wipe the dirt from the fittings before fresh grease is

added. Use the hourmeter to determine service intervals. Do not use the warning lights to

determine the

service intervals.

IMPORTANT:

The

intervals of time between services are based on the average operating

conditions. In severe conditions of operation reduce the interval of time between the services.

Chart 1.

Service

Interval

Ref.No

Point of Service

Service

Points

Lubricant

Service

Every

10 Hours

1

2

3

4

5

6

3

Ground Level Inspection

Brake Fluid Level

Radiator Coolant Level

Engine Crankcase Oil Level

Hydraulic Reservoir Oil Level

Transmission Oil Level

Fuel Tank

Water Separator

1

1

1

1

1

1

1

-

-

-

EO1

HDTF/EO2

HDTF

-

-

Perform

Check

Check

Check

Check

Check

Drain Water

and Sediment

Summary of Contents for 515C

Page 3: ...OM515C520C99 1E DRESSTA ...

Page 5: ......

Page 7: ......

Page 10: ...SECTION 1 INTRODUCTION ...

Page 12: ......

Page 17: ...SECTION 2 SAFETY PRECAUTIONS ...

Page 19: ......

Page 37: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Page 39: ......

Page 49: ...SECTION 4 OPERATING ...

Page 51: ......

Page 107: ...SECTION 5 MAINTENANCE ...

Page 165: ...SECTION 6 SPECIFICATIONS ...

Page 167: ......

Page 181: ...SECTION 6 SPECIFICATIONS Page 16 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...

Page 182: ...SPECIFICATIONS SECTION 6 Page 17 DRESSTA OM515C520C99 1E WIRING DIAGRAMS ...

Page 187: ...SECTION 6 SPECIFICATIONS Page 22 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...