SECTION 4

OPERATING

Page 42

OM515C520C99/1E

DRESSTA

LOADER TECHNIQUES

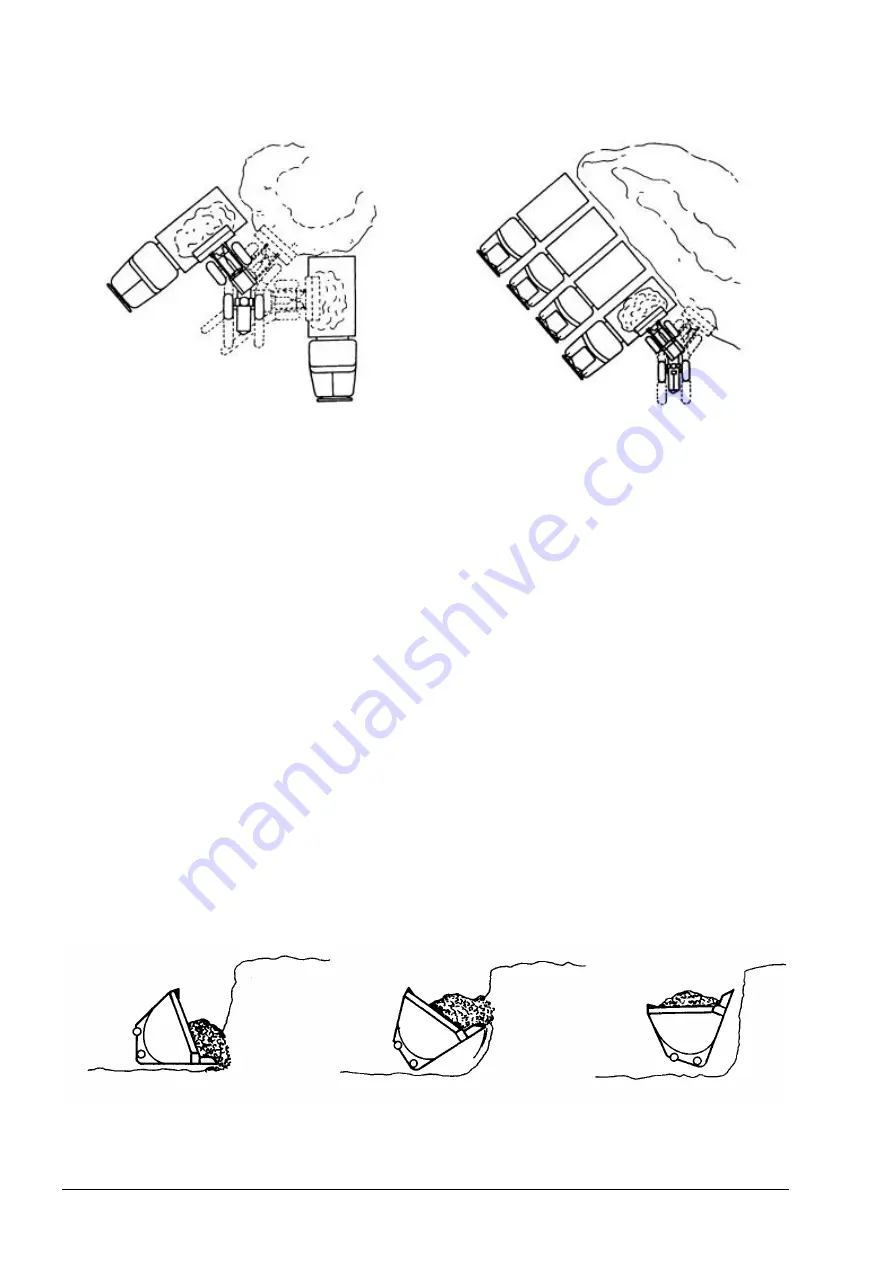

Fig. 4.38."V" Loading Method

Fig. 4.39. Step Loading Method

Approach the bank or stockpile with the engine at full governed speed. Keep the bucket flat, working

into the material at or near ground level. As the bucket penetrates the material, raise the bucket

slightly. When the material boils to the top of the spillboard, roll the bucket all the way back, raise

the bucket to provide ground clearance and, at the same time, disengage the forward travel of the

loader as shown in Fig. 4.38. Back away in an arc from the bank or stockpile as show in Fig. 4.38

and 4.39 just far enough to allow turning of the loader for the approach to the truck. Digging in hard

material can be aided by "wiggling" the bucket edge immediately after penetration. Operate the

bucket control lever alternately between the roll back and dump positions. This action will loosen the

material and improve bucket loading. Coordinated operation of the two hydraulic control levers as

the bucket enters the material will yield satisfactory bucket loads. The boom assy need not be fully

raised to dump the bucket. Adjust the dump height to the height of the side of the loaded vehicle.

NOTE:

The boom assembly need not be fully raised to load the bucket. Maximum bucket loading

can be obtained before the bucket reaches the operator’s eye level.

Approach the bank or stockpile with the engine at full governed speed. Keep the bucket flat, working

into the material at or near ground level. As the bucket penetrates the material, raise the bucket

slightly. When the material boils to the top of the spillboard, roll the bucket all the way back (Fig.

4.40 and 4.41).

Raise the bucket to provide ground clearance and, at the same time, disengage the forward travel

of the loader. Back away in an arc from the bank or stockpile as shown in Fig. 4.38 and 4.39 just far

enough to allow turning of the loader for the approach to the truck.

Fig. 4.40. Bank Loading (Working into Material)

Summary of Contents for 515C

Page 3: ...OM515C520C99 1E DRESSTA ...

Page 5: ......

Page 7: ......

Page 10: ...SECTION 1 INTRODUCTION ...

Page 12: ......

Page 17: ...SECTION 2 SAFETY PRECAUTIONS ...

Page 19: ......

Page 37: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Page 39: ......

Page 49: ...SECTION 4 OPERATING ...

Page 51: ......

Page 107: ...SECTION 5 MAINTENANCE ...

Page 165: ...SECTION 6 SPECIFICATIONS ...

Page 167: ......

Page 181: ...SECTION 6 SPECIFICATIONS Page 16 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...

Page 182: ...SPECIFICATIONS SECTION 6 Page 17 DRESSTA OM515C520C99 1E WIRING DIAGRAMS ...

Page 187: ...SECTION 6 SPECIFICATIONS Page 22 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...