SECTION 5

MAINTENANCE

Page 12

OM560C99/1E

DRESSTA

LUBRICATION

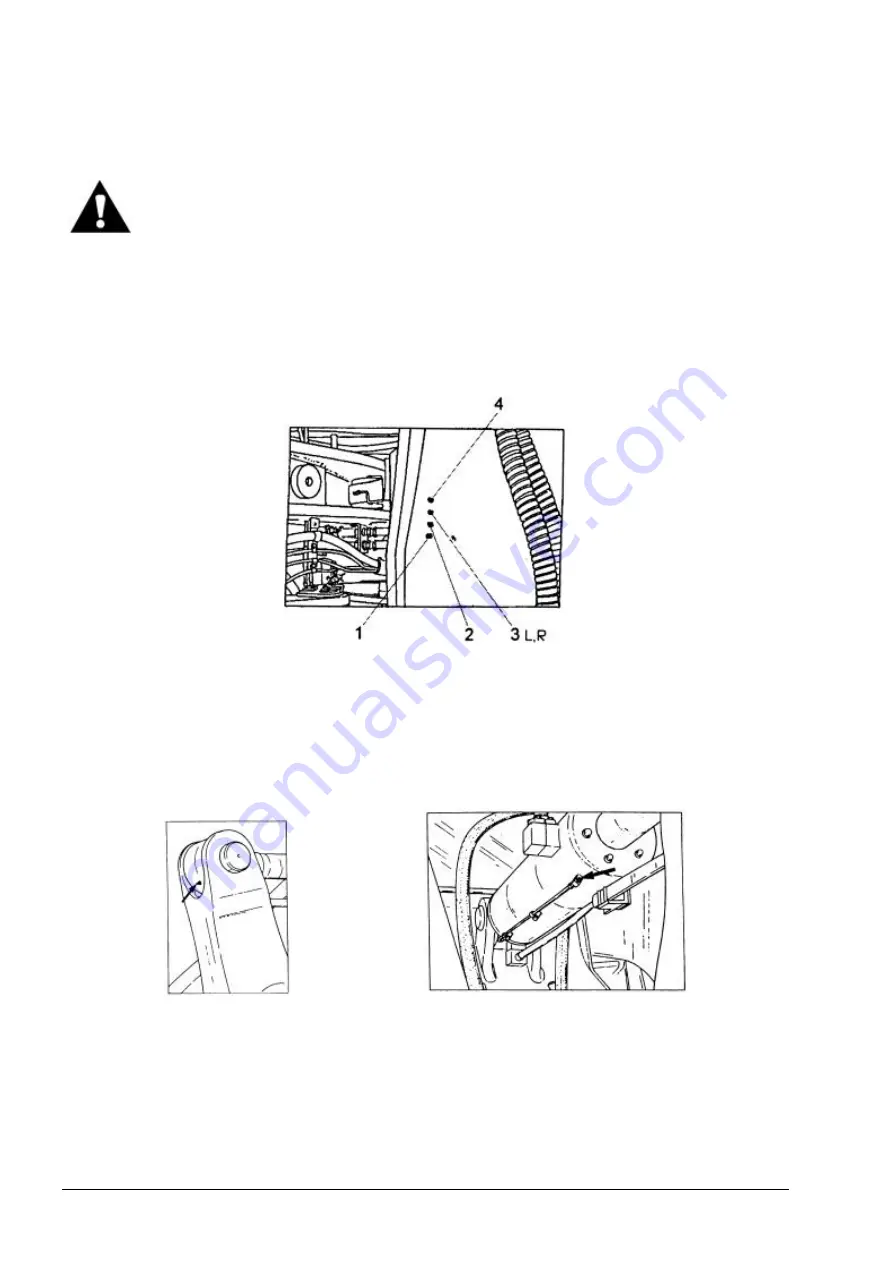

5.4.7. LUBRICATING FITTINGS

WARNING! Never run the engine when cleaning or lubricating the machine

because serious injury could result from contacting moving parts. Before

servicing the machine, be sure the engine is off, the bucket is lowered, the

transmission range gear lever locked in neutral position, the parking brake

applied and the electrical master switch is off and the key is removed.

The lubricating fittings (see Fig. 5.1.) are to be greased at the intervals indicated in the service

chart. Always use a clean lubricator. Wipe all accumulated dirt from fittings before applying fresh

grease. Apply grease at each fitting until fresh grease appears. If grease fails to go through the

fitting, determine the cause and correct it.

Fig. 5.2. Lubricating Fittings

1 - Transfer Drive

2 - Lower Articulation Pivot

3 - Steering Cylinders

4 - Upper Articulation Pivot

L, R- fittings are located on the left (L) hand side and right (R) hand side of the machine frame.

Lubricating fittings of other service points are shown in Fig. 5.3. to 5.8. Easier access to service

points may be gained by proper positioning of loader linkage.

Fig. 5.3. Bucket Cylinder Pivot Fittings

Summary of Contents for 560C

Page 1: ...OM560C99 1E OPERATOR S MANUAL 560C SERIAL NUMBERS 15001 AND UP ...

Page 3: ......

Page 5: ......

Page 7: ......

Page 10: ...SECTION 1 INTRODUCTION ...

Page 12: ......

Page 16: ...SECTION 2 SAFETY PRECAUTIONS ...

Page 18: ......

Page 32: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Page 34: ......

Page 42: ...SECTION 4 OPERATING ...

Page 43: ......

Page 45: ......

Page 49: ...SECTION 4 OPERATING Page 6 OM560C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Page 88: ...SECTION 5 MAINTENANCE ...

Page 141: ...SECTION 6 SPECIFICATIONS ...

Page 143: ......