MAINTENANCE

SECTION 5

Page 25

DRESSTA

OM560C99/1E

COOLING SYSTEM

WARNING! Do not mix types of antifreeze solutions. Mixed solutions make it

impossible to determine the protection against freezing. Antifreeze containing

sealer or anti-leak additives should not be used in this system. Sealer or anti-

leak additives will plug the coolant filter and cause plugging problems in the

cooling system.

Table included in Engine Manual shows percentage of antifreeze concentration required for various

temperatures.

5.8.3. INHIBITORS / CONDITIONERS

1. All cooling system inhibitors, including those in antifreeze solutions, become depleted through

normal operation. If the inhibitors in antifreeze are allowed to become depleted, the antifreeze

becomes corrosive and attacks and coats the metallic surfaces of the cooling system, which

reduces heat transfer. Cooling system conditioners which contain these inhibitors must be

added to maintain corrosion protection.

2. SOLUBLE OIL IS NOT RECOMMMENDED for use in the engine as its use will reduce heat

transfer.

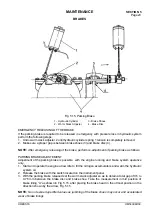

Fig. 5.16. Coolant Filter

REPLENISHING COOLANT CONDITIONER

Replenishing coolant conditioner is performed by periodical replacement of the filters (Fig. 5.16)

containing DCA4 inhibitor protecting the cooling system against corrosion and cavitation erosion of

the cylinder sleeves and coolant pump blades.

COOLANT TESTING FOR CONDITIONER CONCENTRATION

Coolant testing for DCA4 concentration should be performed periodically before the coolant filter

replacement to determine the proper capacity of a filter to be applied. CC2626 test kit of the filter

manufacturer is designed for this purpose. The test procedure is included in the Engine Manual.

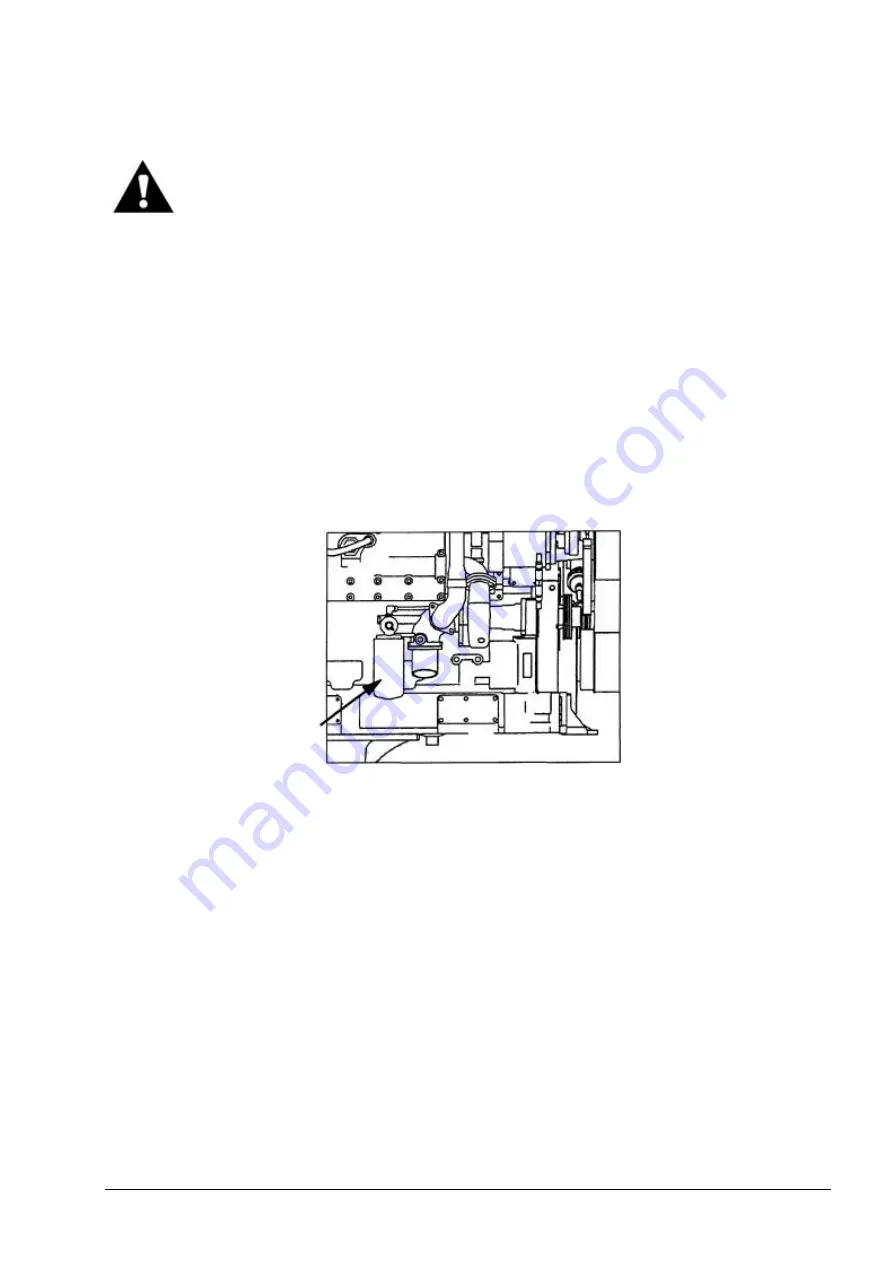

Prior to installation of a new coolant filter close the shut-off valve (Fig. 5.21) - OFF position. Upon

installation of a new coolant filter open the shut-off valve - ON position.

NOTE:

Mixing of DCA4 and other supplemental coolant additives is not recommended because

there is currently no test kit available to measure concentration levels with mixed chemical

solutions.

Summary of Contents for 560C

Page 1: ...OM560C99 1E OPERATOR S MANUAL 560C SERIAL NUMBERS 15001 AND UP ...

Page 3: ......

Page 5: ......

Page 7: ......

Page 10: ...SECTION 1 INTRODUCTION ...

Page 12: ......

Page 16: ...SECTION 2 SAFETY PRECAUTIONS ...

Page 18: ......

Page 32: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Page 34: ......

Page 42: ...SECTION 4 OPERATING ...

Page 43: ......

Page 45: ......

Page 49: ...SECTION 4 OPERATING Page 6 OM560C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Page 88: ...SECTION 5 MAINTENANCE ...

Page 141: ...SECTION 6 SPECIFICATIONS ...

Page 143: ......