SECTION 5

MAINTENANCE

Page 38

OM560C99/1E

DRESSTA

ENGINE

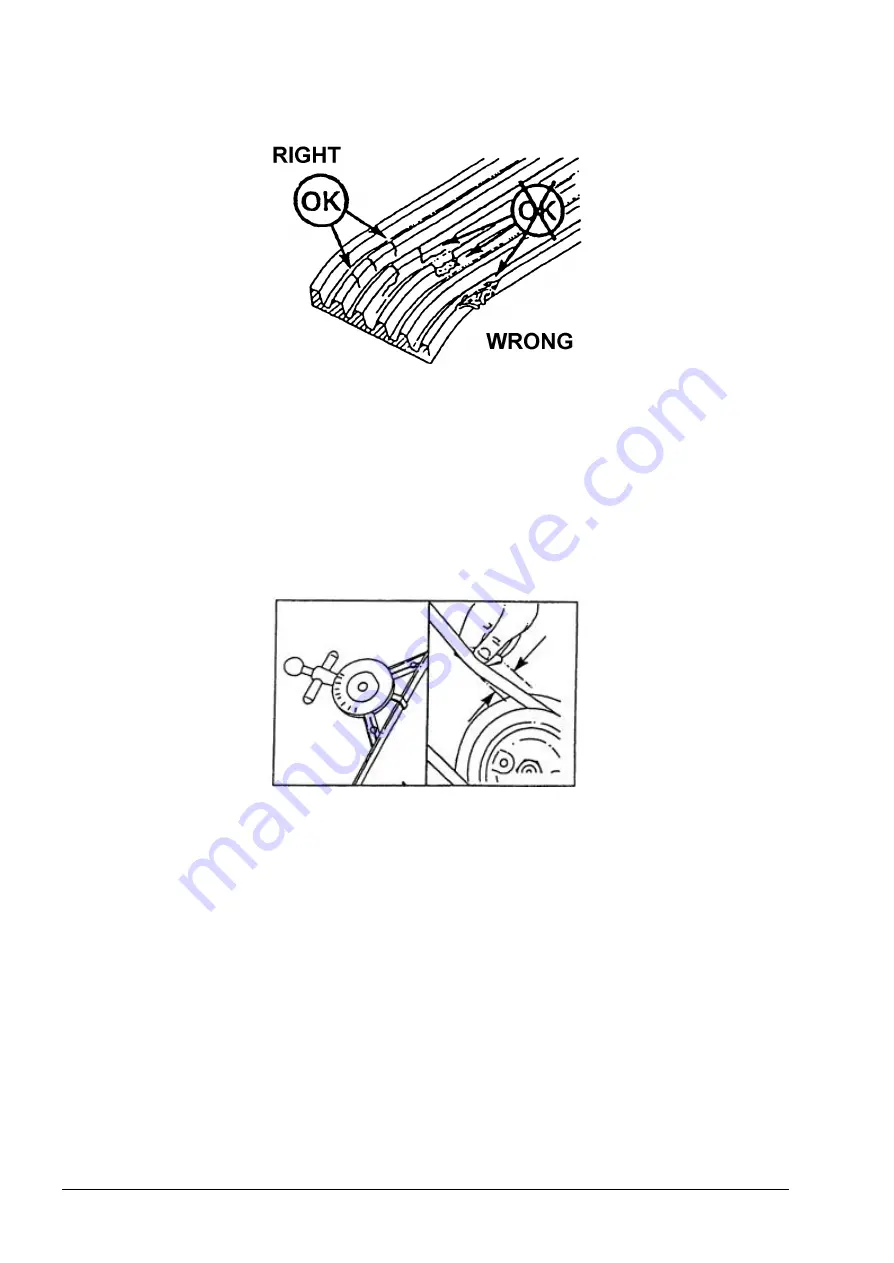

Fig. 5.36. Belt Inspection

Belt damage may occur due to:

−

improper tension,

−

improper installation,

−

severe operating conditions,

−

contamination with oil or grease.

CHECKING THE TENSION

Check the bet tension midway at the longest span between the pulleys using a tension gauge.

Fig. 5.37. Checking Belt Tension

Refer to Engine Operation Manual for the type of a tension gauge as well as the tension values for

various belt widths.

For QSK 19-C (5-groove belt) these values are as follows: a new belt tension 670 N, retension 270

to 530 N.

For KT 19-C (15-groove belt) those values are as follows: a new belt tension 1670 N, retension 670

to 1340 N.

A belt is considered used when operated at least 10 minutes.

Alternately belt tension may be checked by pressing the belt midway between pulleys as shown in

Fig. 5.37. Deflection under a force of 110 N should nor exceed belt thickness at a 30 cm distance

between the pulleys. Adjust the belt if deflection exceeds the above value. New belts loose their

tension during operation.

Summary of Contents for 560C

Page 1: ...OM560C99 1E OPERATOR S MANUAL 560C SERIAL NUMBERS 15001 AND UP ...

Page 3: ......

Page 5: ......

Page 7: ......

Page 10: ...SECTION 1 INTRODUCTION ...

Page 12: ......

Page 16: ...SECTION 2 SAFETY PRECAUTIONS ...

Page 18: ......

Page 32: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Page 34: ......

Page 42: ...SECTION 4 OPERATING ...

Page 43: ......

Page 45: ......

Page 49: ...SECTION 4 OPERATING Page 6 OM560C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Page 88: ...SECTION 5 MAINTENANCE ...

Page 141: ...SECTION 6 SPECIFICATIONS ...

Page 143: ......