SECTION 5

MAINTENANCE

Page 42

OM560C99/1E

DRESSTA

FUEL SYSTEM

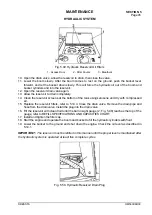

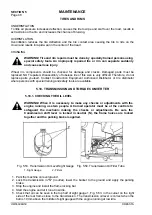

Fig. 5.43. Method of Fuel Filter Installation

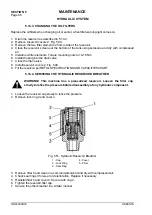

Fig. 5.44. Draining Fuel Filter Water Separator

Fuel filters are equipped with water separators., Fig. 5.44.

To drain water and sediment carry out as follows:

– stop the engine,

– turn the water separator drain valve to the left by 1.5 to 2 turns,

– drain the water until clear fuel start to flow,

– close the valve by turning home to the right.

NOTE:

Do not overtighten the valve not to damage valve thread.

5.13.2. FUEL TANK

FUEL STRAINER

The fuel strainer is installed in filler pipe (1, Fig. 5.45). Access is possible upon the removal of the

filler cap and retainer. The fuel strainer performs a coarse filtration of the fuel facilitating the

operation of the fuel filters. Keep the fuel strainer clean. Use kerosene or diesel fuel for cleaning.

FUEL LEVEL SIGHT GAUGE

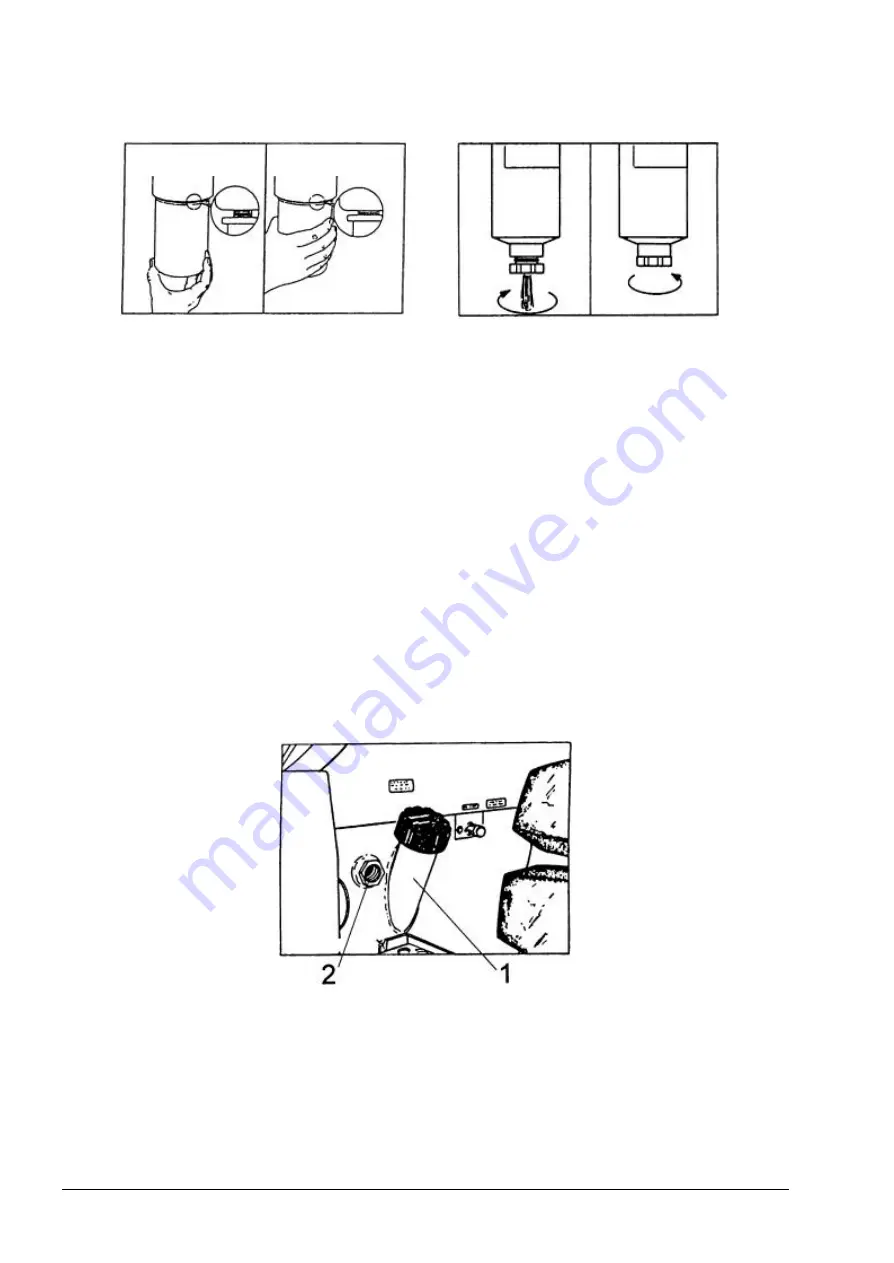

Fig. 5.45. Fuel Tank

1 - Filler Pipe 2 - Sight Gauge

Sight gauge (2, Fig. 5.45.) is located on the right side of the fuel tank. If the fuel level is not visible in

the gauge, fill the tank. To prevent moisture due to condensation, the fuel tank should be refilled at

the end of each day’s operation.

Summary of Contents for 560C

Page 1: ...OM560C99 1E OPERATOR S MANUAL 560C SERIAL NUMBERS 15001 AND UP ...

Page 3: ......

Page 5: ......

Page 7: ......

Page 10: ...SECTION 1 INTRODUCTION ...

Page 12: ......

Page 16: ...SECTION 2 SAFETY PRECAUTIONS ...

Page 18: ......

Page 32: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Page 34: ......

Page 42: ...SECTION 4 OPERATING ...

Page 43: ......

Page 45: ......

Page 49: ...SECTION 4 OPERATING Page 6 OM560C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Page 88: ...SECTION 5 MAINTENANCE ...

Page 141: ...SECTION 6 SPECIFICATIONS ...

Page 143: ......