MAINTENANCE

SECTION 5

Page 9

DRESSTA

OM560C99/1E

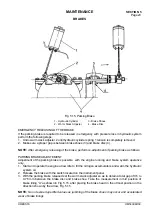

5.4. LUBRICATION

5.4.1. WHEN SHIPPED

This Wheel Loader has been lubricated at the factory for operation in an air temperature range of

+21

°

C to -23

°

C. If this machine is to be operated above or below this range, change to the correct

lubricants. Unless an exception is shown below, all lubricants can be used (within above

temperature range) until regular scheduled (normal) change intervals occur. Refer to "SERVICE

CHART" for the scheduled (normal) change intervals and to "REFILL SPECIFICATIONS AND

CAPACITIES" for the proper oil grades for ambient temperatures.

5.4.2. WHEN SERVICED

The life and performance of a wheel loader and its equipment depends on the service that it is

given. Proper lubrication is an important part of the maintenance service.

Thorough lubrication service performed at the specified intervals will aid in prolonging the life of the

loader and its equipment and in reducing operating expense. The type of work being done, load,

ground and weather conditions are all factors to consider in frequency of lubrication.

The scheduled intervals between the lubrication periods shown on the "SERVICE CHART" are

approximate, based on average operating conditions. It may be necessary to lubricate after shorter

working periods under severe operating conditions such as extreme dust, low engine temperatures,

intermittent operation, excessively heavy loads with high oil temperatures, or when diesel fuel with a

high sulfur content is used. However, the time intervals between lubrication periods must never

exceed those indicated in this manual.

5.4.3. LUBRICANT SELECTION

The selection of the proper type (specification) and the grade (weight or viscosity) of lubricant is

important.

Many tests have been made to determine the correct lubricants for this wheel loader and its

equipment.

5.4.4. VISCOSITIES

During cold weather, base the selection of a crankcase lubricating oil viscosity on the lowest

anticipated temperature for the day to make starting easier. For hot weather operation, base the

selection on the highest anticipated temperature. Refer to the "REFILL SPECIFICATIONS AND

CAPACITIES" chart.

Summary of Contents for 560C

Page 1: ...OM560C99 1E OPERATOR S MANUAL 560C SERIAL NUMBERS 15001 AND UP ...

Page 3: ......

Page 5: ......

Page 7: ......

Page 10: ...SECTION 1 INTRODUCTION ...

Page 12: ......

Page 16: ...SECTION 2 SAFETY PRECAUTIONS ...

Page 18: ......

Page 32: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Page 34: ......

Page 42: ...SECTION 4 OPERATING ...

Page 43: ......

Page 45: ......

Page 49: ...SECTION 4 OPERATING Page 6 OM560C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Page 88: ...SECTION 5 MAINTENANCE ...

Page 141: ...SECTION 6 SPECIFICATIONS ...

Page 143: ......