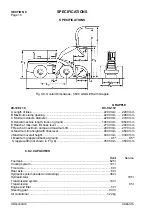

SPECIFICATIONS

SECTION 6

Page 3

DRESSTA

OM560C99/1E

6.1. APPLICATION

560C Wheel Loader is a modern machine featuring the following foredesign criteria: optimization of

performance, long service life, reliability, maximum unification of parts and assemblies, simplified

maintenance and serviceability. This rugged loader is designed for continuous heavy reloading

operations. It is particularly useful for loading heavy dump trucks. Wheel loader may also perform

the following works:

n

Bank loading of cohesive soils,

n

Dozing and stockpiling,

n

Digging and excavating,

n

Snow removal from streets and squares,

n

Transport building semi-products for short distances,

n

Backdragging and leveling.

The scope of works may be increased by the application of specialized equipment mounted instead

of a standard bucket and high-lift boom.

6.2. TECHNICAL DESCRIPTION

Main units of the wheel loader include:

n

Chassis,

n

Superstructure,

n

loader linkage system and mounted equipment.

CHASSIS

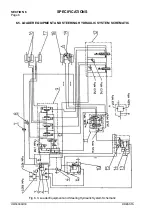

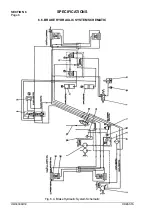

The chassis includes an articulated frame supported on two drive axles. The front one is rigidly

mounted to the frame, whereas the rear one is trunnion mounted and oscillates allowing the

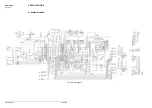

machine to operate in uneven ground. The chassis comprises hydraulic, compressed air, electrical

and cooling systems, as well as drive train that consists of torque converter, transmission, drive

shafts, drive axles.

SUPERSTRUCTURE

The superstructure consists of a front mounted cab, hood, fenders and platforms, oil, fuel and air

tanks. The instrument panel located in the cab includes gauges necessary for continuous

monitoring operation of the machine and convenient and easy to operate controls of the machine.

The instrument panel is equipped with instruments necessary to control operation of the machine.

The control levers and pushbuttons necessary to operate a machine are located in the cab. The

operator's seat is equipped with armrests and a seat belt. A cab includes ROPS-FOPS protecting

structure providing the operator protection against injury under weight of the machine in the event of

machine rollover or upset. Also, the structure provides protection against falling objects. The cab

meets safety requirements of SAE standard 1040C.

LOADER LINKAGE

The Z-type loader linkage system provides significant dump angle within the whole operating range

of loader linkage system. It features excellent capacity, breakout force and resistance to dynamic

loads ensuring high operational durability and reliability.

Summary of Contents for 560C

Page 1: ...OM560C99 1E OPERATOR S MANUAL 560C SERIAL NUMBERS 15001 AND UP ...

Page 3: ......

Page 5: ......

Page 7: ......

Page 10: ...SECTION 1 INTRODUCTION ...

Page 12: ......

Page 16: ...SECTION 2 SAFETY PRECAUTIONS ...

Page 18: ......

Page 32: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Page 34: ......

Page 42: ...SECTION 4 OPERATING ...

Page 43: ......

Page 45: ......

Page 49: ...SECTION 4 OPERATING Page 6 OM560C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Page 88: ...SECTION 5 MAINTENANCE ...

Page 141: ...SECTION 6 SPECIFICATIONS ...

Page 143: ......