SECTION 3

MACHINE TRANSPORT AND STORAGE

Page 6

OM560C99/1E

DRESSTA

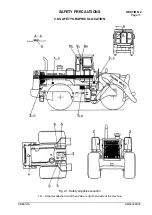

3.3. MOVING A DISABLED MACHINE

Towing this machine is not recommended. To move a disabled machine, use a trailer or low-boy

truck if possible. If towing is necessary, such as freeing a stuck machine, tow it only as far as

necessary. Towing machine backwards is recommended. When towing, the engine must be

running (if operative) to enable turning and braking of the machine.

Towing of machines equipped with ground driven system is easier. Prior to towing release spring

parking brake (refer to PARKING BRAKE, Section 5) and unlock frames by placing locking bar in

stowed position as shown in Fig. 3.1 Use chains or cables of adequate strength, be sure they are

properly secured to the draw bar pin.

WARNING: When pulling with a chain or cable, take up the slack slowly to avoid

jerking. A chain or cable which fails under load can whip and cause serious

injury. Stand clear. Do not pull or tow unless the operator's compartment is

guarded against or out of reach of a whipping chain or cable.

WARNING: Observe safety precautions specified in this manual. Refer to

SAFETY PRECAUTIONS , Section 2.

3.4. MACHINE STORAGE

3.4.1. PREPARING FOR STORAGE

When a machine is taken out of service and stored for a period of time exceeding 30 days, steps

must be taken to protect the machine. Wash and dry the machine and place in dry enclosure. An

enclosure will protect the machine from rapid temperature changes and lessen the amount of

condensation that forms in hydraulic components, engine, fuel tank, axles and transmission.

Leaving equipment outdoors exposed to the elements will materially shorten its life. If it is not

possible to put the machine in an enclosure, cover it with a tarpaulin. After the machine has been

positioned for storage and the engine shutdown, perform the following operations:

1. Visually inspect the machine for external leakage and other defects.

2. Clean the radiator, refer to "COOLING SYSTEM" in Section 5.

3. Thoroughly clean the machine, be sure to rinse off any caustic residue.

4. Correct any defects found. Consult authorized service of manufacturer

5. Clean or replace the air cleaner filter elements. Refer to "AIR CLEANING SYSTEM" in Section

5.

6. The cooling system should be completely drained, chemically flushed, and refilled with a

conditioned water/anti-freeze solution suitable for the lowest temperature anticipated. Refer to

"COOLING SYSTEM" in Section 5 for the proper anti-freeze and conditioner concentrations.

IMPORTANT:

To avoid corrosion, under no circumstances should the machine or cab heaters (if

equipped) be stored with a dry cooling system.

7. Drain the water from the fuel tank. Refer to "FUEL SYSTEM" in Section 5. Clean fuel filter

installed in the filler neck.

8. Remove and replace the fuel filters. Refer to "FUEL SYSTEM" in Section 5.

9. It is recommended to use fuel stabilizer in quantity specified by the manufacturer. Stabilizer will

prevent degrading of fuel, sludge buildup, and stop the growth of bacteria in fuel during storage.

Fuel stabilizer may be purchased from:

Summary of Contents for 560C

Page 1: ...OM560C99 1E OPERATOR S MANUAL 560C SERIAL NUMBERS 15001 AND UP ...

Page 3: ......

Page 5: ......

Page 7: ......

Page 10: ...SECTION 1 INTRODUCTION ...

Page 12: ......

Page 16: ...SECTION 2 SAFETY PRECAUTIONS ...

Page 18: ......

Page 32: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Page 34: ......

Page 42: ...SECTION 4 OPERATING ...

Page 43: ......

Page 45: ......

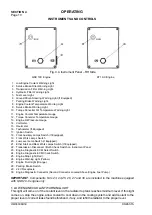

Page 49: ...SECTION 4 OPERATING Page 6 OM560C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Page 88: ...SECTION 5 MAINTENANCE ...

Page 141: ...SECTION 6 SPECIFICATIONS ...

Page 143: ......