OPERATING

SECTION 4

Page 3

DRESSTA

OM560C99/1E

SECTION CONTENTS

C) ................................................... 26

4.12.2. Cold Weather Start (using ether injector) .............................................................. 28

4.12.3. Starting After Oil Change or Longer Storage ......................................................... 28

4.12.4. Stopping the Engine ............................................................................................... 29

Loader Operations ................................................................................................................ 34

4.18.1. Boom Control Lever Positions ............................................................................... 34

4.18.2. Automatic Boom Kick-Out ...................................................................................... 35

4.18.3 Bucket Control Lever Positions .............................................................................. 36

4.18.4. Automatic Bucket Leveler ....................................................................................... 37

Loader Techniques ............................................................................................................... 37

4.19.1. Loading, Transporting and Piling ............................................................................ 37

4.19.2. Digging, Clearing and Leveling ............................................................................... 40

Summary of Contents for 560C

Page 1: ...OM560C99 1E OPERATOR S MANUAL 560C SERIAL NUMBERS 15001 AND UP ...

Page 3: ......

Page 5: ......

Page 7: ......

Page 10: ...SECTION 1 INTRODUCTION ...

Page 12: ......

Page 16: ...SECTION 2 SAFETY PRECAUTIONS ...

Page 18: ......

Page 32: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Page 34: ......

Page 42: ...SECTION 4 OPERATING ...

Page 43: ......

Page 45: ......

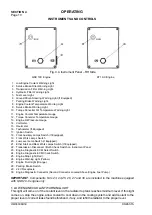

Page 49: ...SECTION 4 OPERATING Page 6 OM560C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Page 88: ...SECTION 5 MAINTENANCE ...

Page 141: ...SECTION 6 SPECIFICATIONS ...

Page 143: ......