OPERATING

SECTION 4

Page 19

DRESSTA

OM560C99/1E

INSTRUMENTS AND CONTROLS

53. CONTROL LEVER LOCKING PLATE (FIG. 4.8)

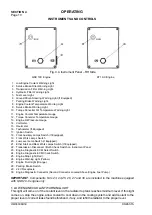

Fig. 4.8. Control Lever Locking Plate

1- Locking Plate

2 - Locking Bar

Locking plate 1 is used to lock the control levers in the neutral position. In the drawing the plate is

shown in the non-locked position.

54. HAZARD LIGHTS WITH CONTROL LIGHT

Switch on hazard lights in case of malfunction of loader in a hazardous place e.g. building site.

Red light comes on when hazard lights are switched on.

55. DIRECTIONAL SIGNAL SWITCH

Used to switch on right or left turn signal (forward or backward movement of the switch).

Green lights come on when the directional signal is switched on.

WARNING! When roading the machine, engage the hydraulic control lever

locking plate. Accidental actuation of the levers may cause personal injury or

damage of the machine.

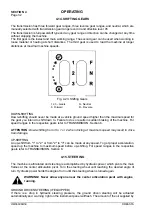

4.4. SUSPENSION SEAT

WARNING! Before driving the machine, adjust the seat and fasten the seat belt.

Adjust the seat belt to fit snugly and low around the hips to lessen the chance

and severity of injury in the event of an accident. Never wear the seat belt

across the abdomen.

WARNING! Do not adjust the seat position while the machine is moving, because

a lose of control may result.

Stop the machine, apply the parking brake and then adjust the seat as described below.

Summary of Contents for 560C

Page 1: ...OM560C99 1E OPERATOR S MANUAL 560C SERIAL NUMBERS 15001 AND UP ...

Page 3: ......

Page 5: ......

Page 7: ......

Page 10: ...SECTION 1 INTRODUCTION ...

Page 12: ......

Page 16: ...SECTION 2 SAFETY PRECAUTIONS ...

Page 18: ......

Page 32: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Page 34: ......

Page 42: ...SECTION 4 OPERATING ...

Page 43: ......

Page 45: ......

Page 49: ...SECTION 4 OPERATING Page 6 OM560C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Page 88: ...SECTION 5 MAINTENANCE ...

Page 141: ...SECTION 6 SPECIFICATIONS ...

Page 143: ......