Page 10

SKU 40070

For technical questions, please call 1-800-444-3353.

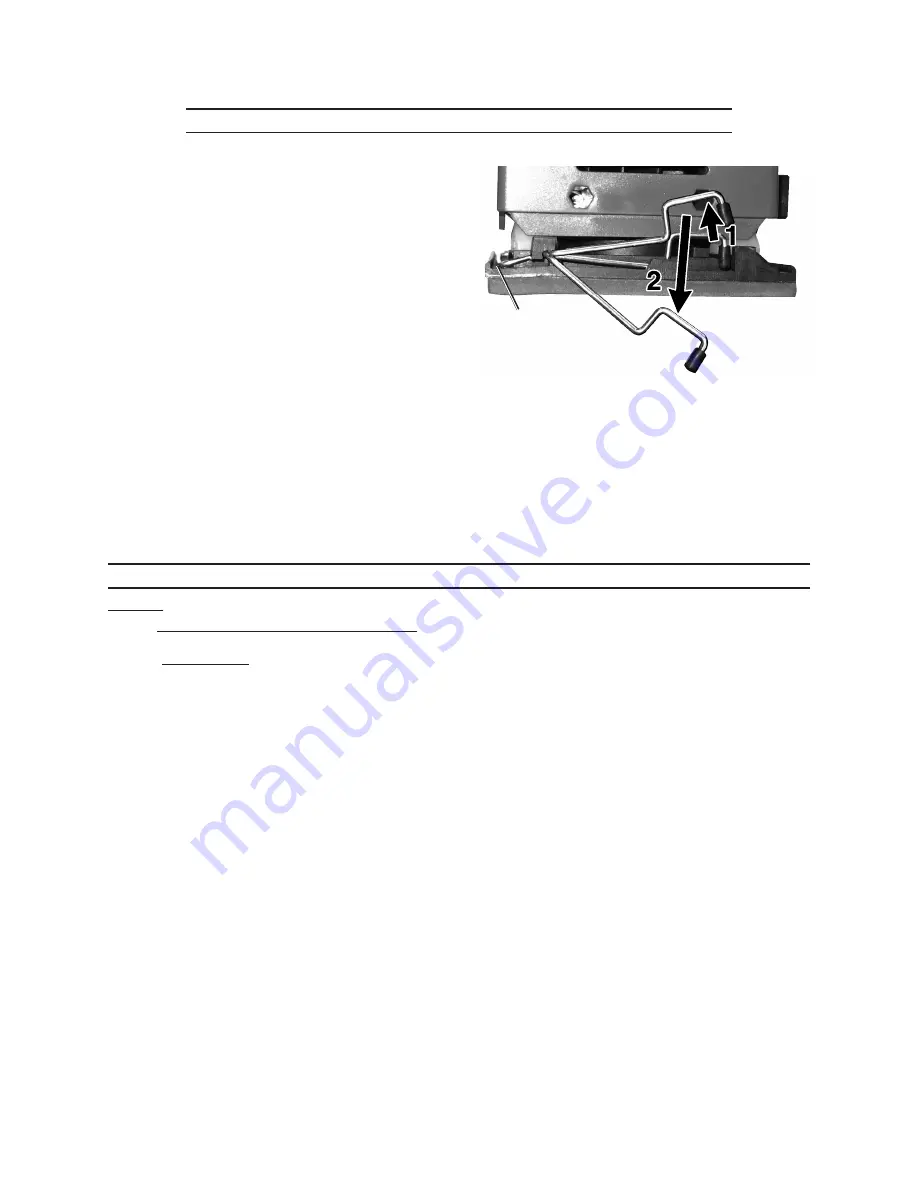

ATTACHING SANDPAPER TO THE BACKING PAD (28)

1.

Press the tab on the

Clamps (6)

inward

on both sides of the unit and swing the

clamps on both sides up, out, and

down. See

1 & 2

, right.

2.

Cut the sandpaper to fit the 4” W x 4

1

/

2

”

L

Pad (28)

, with a little extra to overlap

and fit under the

Clamps (6)

.

Do not

use torn or frayed sandpaper.

3.

After wrapping the overlapped edges

of sandpaper under the

Clamps (6)

,

snap the

Clamps (6)

back into place.

Sandpaper

goes under

here

OPERATING INSTRUCTIONS

NOTE:

For additional information regarding the parts listed in the following pages, refer

to the

Assembly Diagram

on

page 12

.

1.

CAUTION:

Always make sure the Power Cord (17) of the Sander is unplugged from

its electrical outlet

prior to making any adjustments to the tool.

2.

Clamp your workpiece down, or insert it in a vise. Make sure the wood you are

sanding does not have any nails or metal of any kind in it, or you will ruin the

sandpaper and damage the Pad (28).

3.

After donning the appropriate safety gear covered on page 2 of this manual, plug in

the Sander.

4.

Turn on the Sander by turning on the Switch (3).

5.

Always run the Sander for a few seconds before contacting the workpiece.

6.

Contact the workpiece with minimal pressure. If the Sander is not removing enough

material, try a grittier piece of sandpaper. If you want to remove a lot of material fast,

use a belt sander.

Note:

All orbital sanders leave sanding marks on the workpiece. To minimize sanding

marks, always try to sand with the grain of the wood.

7.

Occasionally check the sandpaper for tears, wear, or fraying. Replace if necessary.

8.

When you are finished, turn off the Switch (3).