Page 12

For technical questions, please call 1-800-444-3353.

SKU 66965

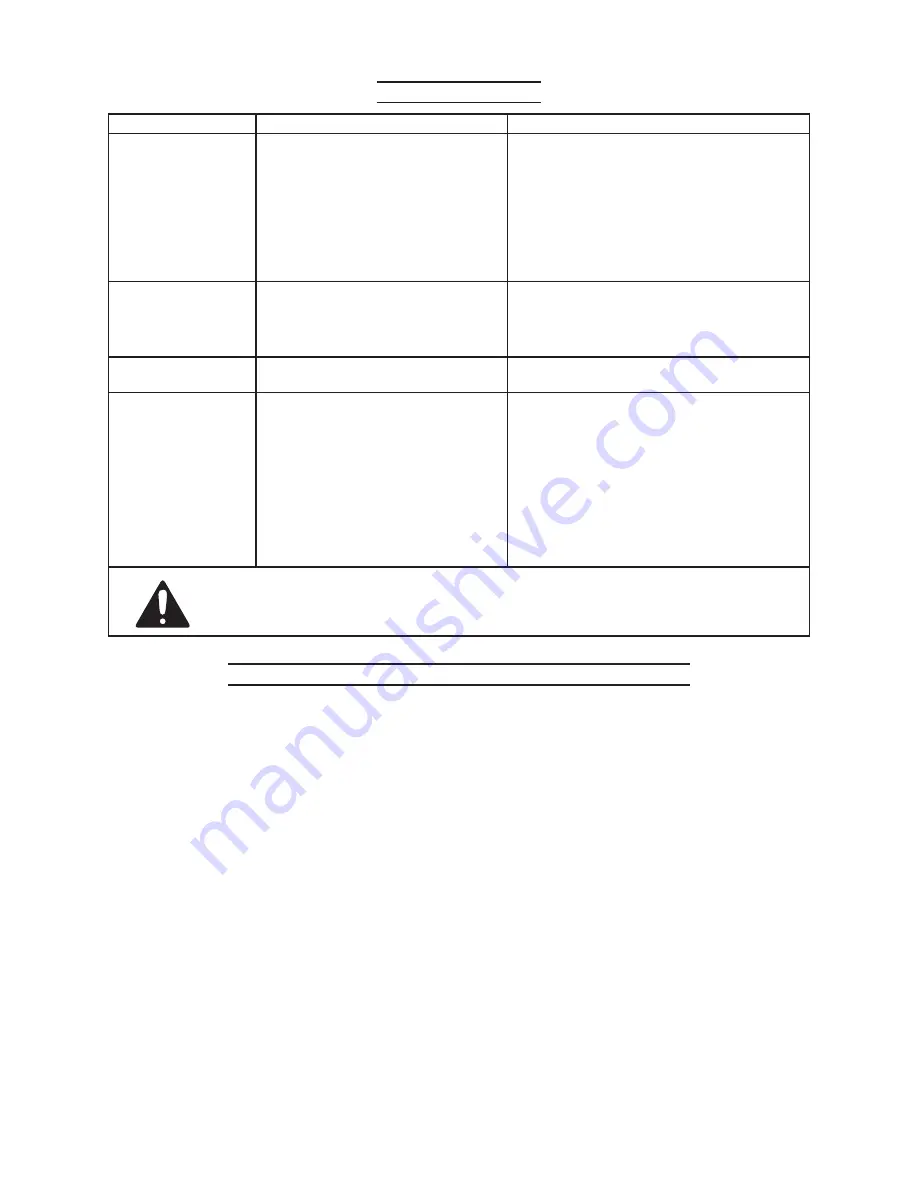

troubleshooting

problem

possible Causes

Likely Solutions

Tool will not start.

No power at outlet during

1.

charging.

Internal damage or wear.

2.

(Carbon brushes or switch, for

example.)

1. Check power at outlet. If outlet is

unpowered, turn off tool and check circuit

breaker. If breaker is tripped, make sure

circuit is right capacity for tool and circuit

has no other loads.

2. Have technician service tool.

Performance

decreases over time.

Accessory dull or damaged.

1.

Carbon brushes worn or

2.

damaged.

Keep accessories sharp. Replace as

1.

needed.

Have qualified technician replace

2.

brushes.

Excessive noise or

rattling.

Internal damage or wear. (Carbon

brushes or bearings, for example.)

Have technician service tool.

Overheating.

Forcing tool to work too fast.

1.

Accessory misaligned.

2.

Accessory dull or damaged.

3.

Blocked motor housing vents.

4.

Allow tool to work at its own rate.

1.

Check and correct accessory to fence

2.

and/or table alignment.

Keep cutting accessories sharp.

3.

Replace as needed.

Wear ANSI-approved safety goggles and

4.

NIOSH-approved dust mask/respirator

while blowing dust out of motor using

compressed air.

Follow all safety precautions whenever diagnosing or servicing the

tool. Disconnect power supply before service.

pLEaSE REaD thE FOLLOWIng CaREFuLLY

THE MANUfACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLy DIAgRAM

IN THIS MANUAL AS A REfERENCE TOOL ONLy. NEITHER THE MANUfACTURER OR DISTRIBUTOR MAkES

ANy REPRESENTATION OR WARRANTy Of ANy kIND TO THE BUyER THAT HE OR SHE IS qUALIfIED TO

MAkE ANy REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS qUALIfIED TO REPLACE ANy PARTS

Of THE PRODUCT. IN fACT, THE MANUfACTURER AND/OR DISTRIBUTOR ExPRESSLy STATES THAT

ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAkEN By CERTIfIED AND LICENSED

TECHNICIANS, AND NOT By THE BUyER. THE BUyER ASSUMES ALL RISk AND LIABILITy ARISINg OUT

Of HIS OR HER REPAIRS TO THE ORIgINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISINg

OUT Of HIS OR HER INSTALLATION Of REPLACEMENT PARTS THERETO.