Page 6

For technical questions, please call 1-800-444-3353.

Item 69947

SAFET

y

Op

ERA

TION

M

AINTENAN

c

E

SETU

p

Grounding

TO pREVENT ELEcTRIc SHOcK AND DEATH FROM

INcORREcT GROUNDING WIRE cONNEcTION:

check with a qualified electrician if you are in doubt as to whether the outlet is

properly grounded. Do not modify the power cord plug provided with the tool. Never

remove the grounding prong from the plug. Do not use the tool if the power cord or plug is

damaged. If damaged, have it repaired by a service facility before use. If the plug will not fit the

outlet, have a proper outlet installed by a qualified electrician.

Grounded Tools: Tools with Three prong plugs

Figure A: 3-prong plug and Outlet

1. Tools marked with “Grounding Required”

have a three wire cord and three prong

grounding plug. The plug must be connected

to a properly grounded outlet. If the tool

should electrically malfunction or break down,

grounding provides a low resistance path to

carry electricity away from the user, reducing

the risk of electric shock.

(See Figure A.)

2. The grounding prong in the plug is

connected through the green wire inside

the cord to the grounding system in the tool.

The green wire in the cord must be the

only wire connected to the tool’s grounding

system and must never be attached to an

electrically “live” terminal.

(See Figure A.)

3. The tool must be plugged into an appropriate

outlet, properly installed and grounded in

accordance with all codes and ordinances.

The plug and outlet should look like those in

the preceding illustration.

(See Figure A.)

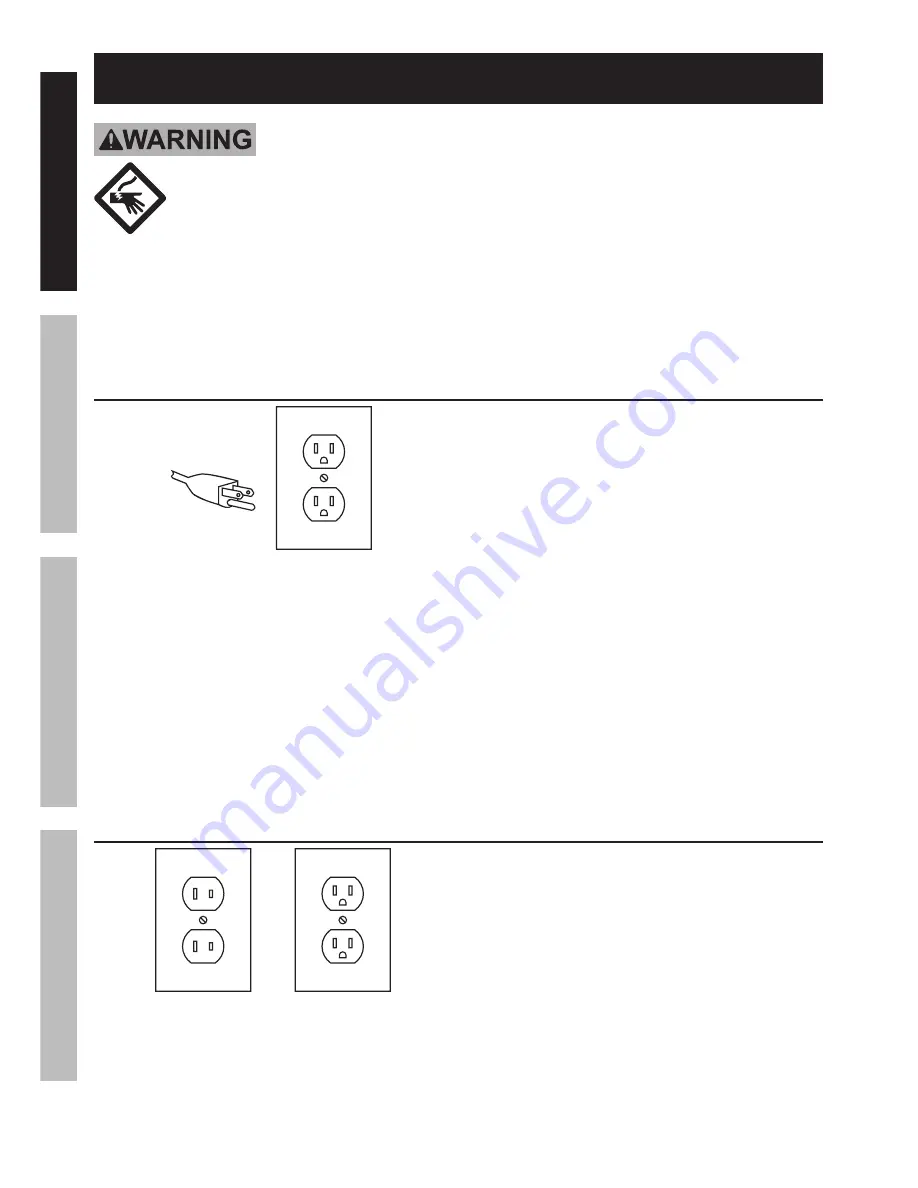

Double Insulated Tools: Tools with Two prong plugs

Figure B: Outlets for 2-prong plug

1. Tools marked “Double Insulated” do not

require grounding. They have a special

double insulation system which satisfies OSHA

requirements and complies with the applicable

standards of Underwriters Laboratories, Inc.,

the Canadian Standard Association,

and the National Electrical Code.

2. Double insulated tools may be used in

either of the 120 volt outlets shown in the

preceding illustration.

(See Figure B.)

Summary of Contents for 69947

Page 1: ......