Drivecon Inc. reserves the right to alter or amend the above information without notice.

Page 14 of 18

While the system is in service mode the “envelope” icon in the

display will be switched ON. (Figure 10).

Figure 10

LCD Display in Service Mode

6.3 Keys for moving within the Menus.

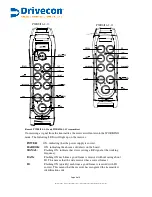

The keys for moving within the menu are the following (Figure

9):

UP: Button that simulates the Up Key. Up button.

_

DOWN: Button that simulate the Down Key. Down button.

_

ESC: Button that simulate the Esc Key. Left button.

_

ENTER: Button that simulate the Enter Key. Right button.

_

Figure 11

Pushbutton as a Key board for Hoist Condition Monitoring Unit

6.4 Switching from Tared Load to Actual Load.

The actual load is shown in the display unit as the Tared Load, but an “A” is shown below the

“t” in the bottom right hand side of the display unit. In order to switch from Tared Load to

actual load, this is performed by pressing UP and/or DOWN. Pressing ENTER, the password is

requested.

Figure 12

LCD representing Tared Load

6.5 Resetting the Tared Load.

Pressing the ESC button for several seconds performs the reset of

the Tared Load.