Classic With Blower Installation and Operation Manual

32

8 The Venting System

8.1

General

The venting system, made up of the chimney and the connecting pipe between the stove

and the chimney, acts as the engine that drives your wood heating system. Even the best

stove will not function safely and efficiently as intended if it is not connected to a suitable

chimney.

The heat in the flue gases that pass from the stove and chimney connector into the

chimney is not waste heat. This heat is what the chimney uses to make the draft that

draws in combustion air, keeps smoke inside the stove and safely vents exhaust to

outside. You can think of heat in the flue gas as the fuel the chimney uses to make draft.

8.2

Suitable Chimneys

Your wood stove will provide optimum efficiency and performance when connected to a 6-

inch diameter chimney flue system. The connection to a chimney having a diameter of at

least 5 inches (Canada only) or no more than 7 inches is permitted, if it allows the proper

venting of combustion gases and that such application is verified and authorized by a

qualified installer. Otherwise, the diameter of the flue should be 6 inches.

To be suitable, a factory-built metal chimney

must comply with UL 103 (U.S.A.) or ULC

S629 (Canada).

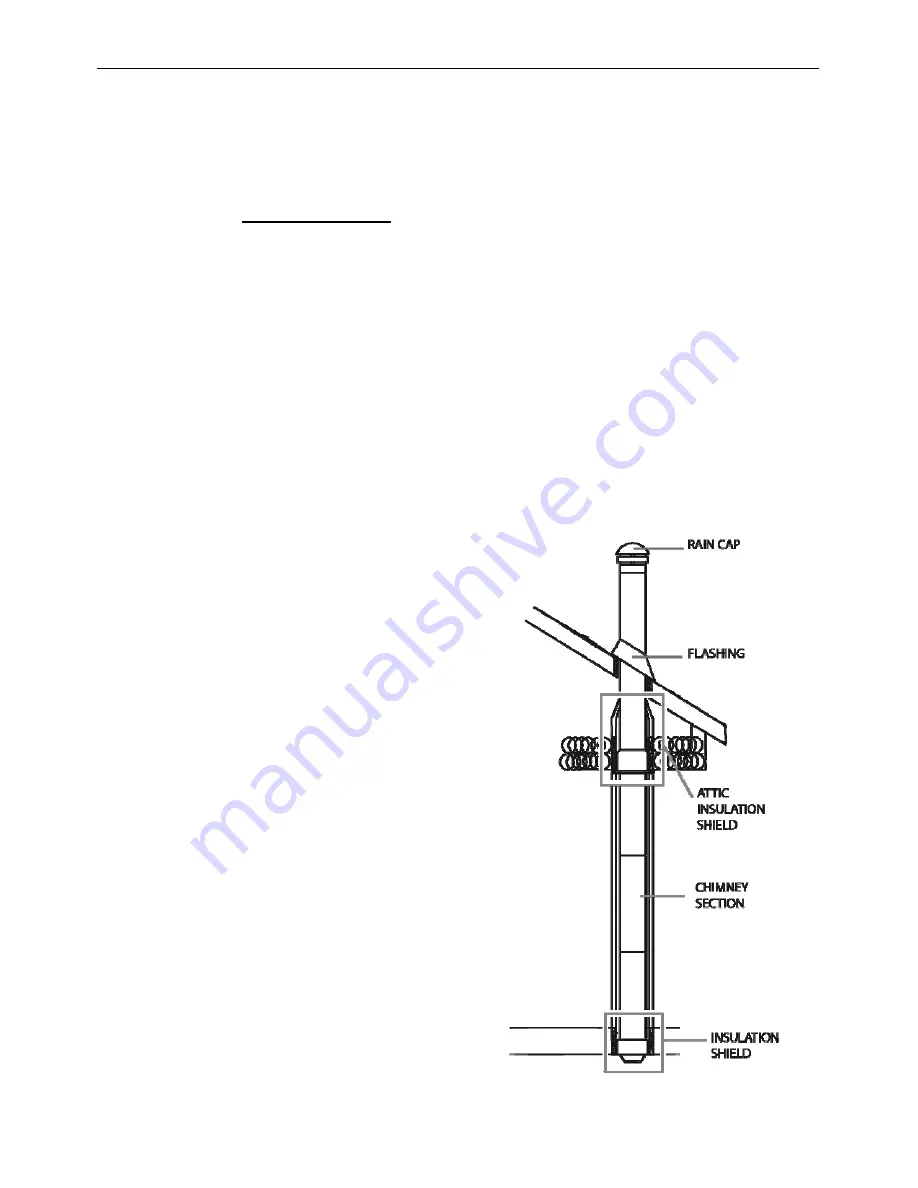

8.2.1 Factory-built

Metal

Chimneys

These are sometimes referred to as ‘high

temp’ chimneys because they have the

special characteristics to withstand the

temperatures that can be created by wood

burning stoves. Factory-built chimneys are

tested as a system with all the necessary

components for installation. The instructions

provided with the chimney by its

manufacturer are the only reliable source of

installation guidelines. To be safe and

effective, the chimney must be installed

exactly in accordance with the

manufacturer’s instructions.

Use only

components intended for the brand and

model of chimney you are using. Never

substitute parts from other chimney

brands or fabricate your own

components. The chimney must be a type

suitable for solid fuel.