Installation and Operation Manual for Escape 1800

34

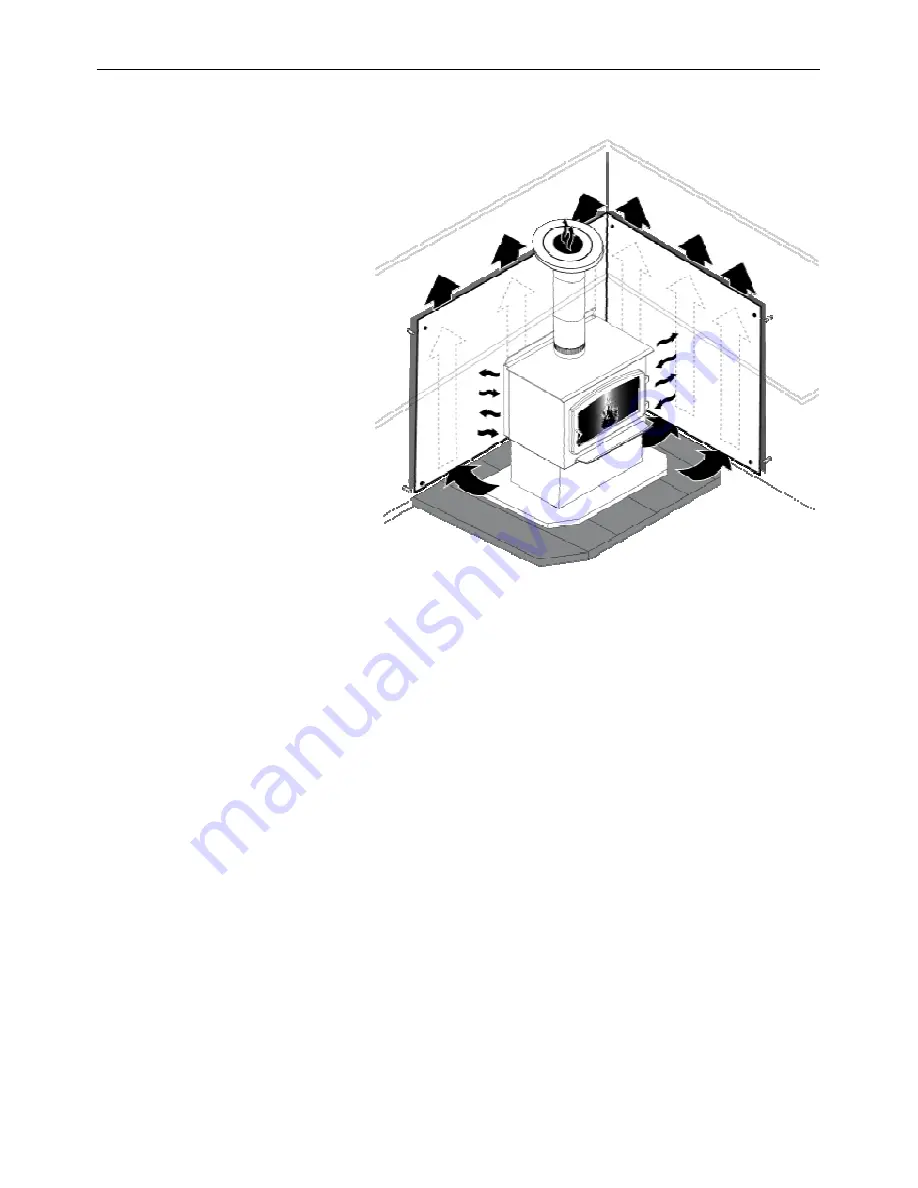

7.4 Reducing Wall and Ceiling Clearances Safely

It is often desirable to reduce

the

minimum

installation

clearances by placing the stove

closer

to

walls

so

the

installation takes up less floor

space. You can safely reduce

the minimum clearances by

permanently installing a shield

between

the

stove

and

combustible material. The rules

for

safe

shields

can

be

complicated, so read them

carefully

and

follow

them

exactly. Note that there may be

minor regional differences in

clearance reduction rules so be

sure to check with your building

or

fire

inspector

before

proceeding.

7.4.1 Shield Construction Rules

1. Minimum space behind shield: 25 mm (1 in.). In Canada 21 mm (7/8 in).

2. Minimum clearance along the bottom of shield: 25 mm (1 in.).

3. Maximum clearance along the bottom of shield: 75 mm (3 in.).

4. Minimum clearance along the top of shield at ceiling: 75 mm (3 in.).

5. Shield extension beyond each side of appliance: 450 mm (18 in.).

6. Shield extension above appliance: 500 mm (20 in.).

7. Edge clearance for ceiling shields: 75 mm (3 in.).

8. Adhesives used in shield construction must not ignite or lose adhesive qualities at

temperatures likely to be encountered.

9. Mounting hardware must allow full vertical ventilation.

10. Mounting hardware must not be located closer than 200 mm (8 in.) from the vertical

centre line of the appliance.

11. Mounting hardware which extends from the shield surface into combustibles may be

used only at the edges of the shield.