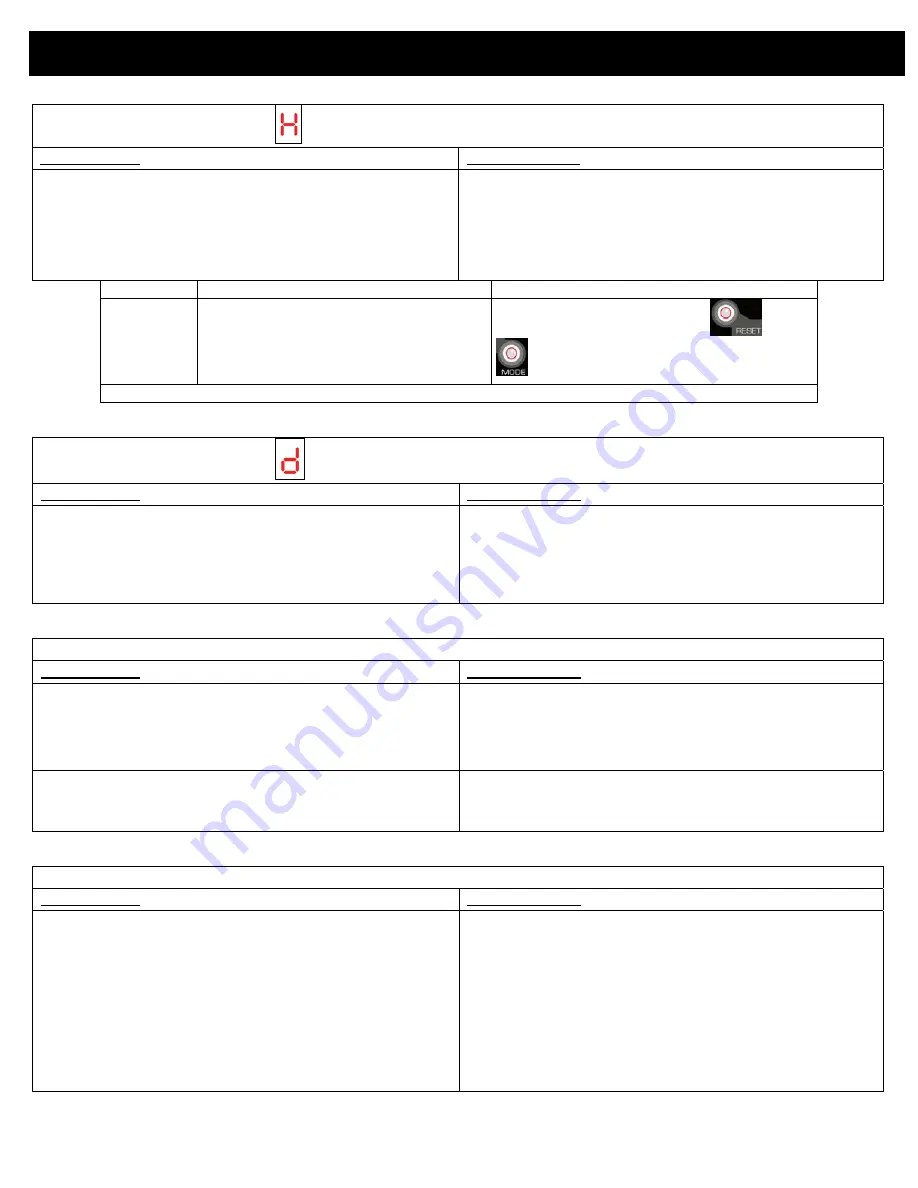

STOVE STOPS FEEDING PELLETS AND

APPEARS ON THE CONTROL BOARD

Possible Causes: Possible

Remedies:

1.

One of the two L-250 automatic high temperature switches has been tripped.

The L-250 automatic high temperature switch is located on the auger

housing and will send a signal to the control board if the auger housing

overheats. Wait until the stove cools down. YOU NEED TO INSPECT

YOUR UNIT AT THIS POINT. There might be a problem with another

component or the installation, causing the stove to overheat. Reset the

stove and start it. Call a technician if you get this code again.

CODE BEFORE

RESETING

TO

RESET

H1, H2, H3

OR H4

Heat exchanger and/or exhaust system

is/are clogged. Refer to the owner’s manual

for maintenance procedures.

Press simultaneously for 2 seconds

and

.

*** After 3 attempts, reset is no longer possible, call SBI technical support.

STOVE STOPS FEEDING PELLETS AND

APPEARS ON THE CONTROL BOARD

Possible Causes: Possible

Remedies:

1. The hopper lid has stayed open for more than 3 minutes

As a security measure, the auger will stop turning and feeding pellets as

soon as the hopper lid opens. It will resume normal operation as soon as the

hopper lid is closed. However, if the hopper lid stays open for more than 3

minutes, the unit will stop and a code “d” will appear on the control board.

Close the hopper lid. Reset the unit and start it again.

SMOKE SMELL COMING BACK INTO THE HOME

Possible Causes: Possible

Remedies:

1. There is a leak in the vent pipe system.

Inspect all vent pipe connections. This is a pressurized exhaust system. All

vent connector joints must be sealed and fastened in accordance with the

pellet pipe manufacturer's instructions to ensure consistent performance and

avoid smoke and ash spillage.

2.

The gasket on the combustion/exhaust blower housing has

gone bad.

Inspect the gasket on the combustion/exhaust blower housing to make sure

it is in good shape.

AUGER MOTOR STOP FEEDING PELLETS AND COMES BACK ON

Possible Causes: Possible

Remedies:

1.

The auger motor is overheating and tripping the internal temperature

shutoff (thermal protector).

Start by emptying the hopper. Then, remove the auger motor by removing

the screws holding the motor to the auger shaft. Remove the plate located

on the stove body, at the bottom of the gear motor, to allow the motor to

slide out of the stove body. Once, the motor is out, remove the four screws

on the steel plate holding the auger shaft to the auger housing. Then, rotate

the bottom end of the auger shaft down towards you until you can pull the

shaft down out of the stove. After you have removed the shaft, inspect it for

bent flights, burrs, or broken welds. Remove any foreign material that might

have caused the jam. Also, check the auger housing for signs of damage

such as burrs, rough spots, or grooves cut into the metal that could have

caused a jam. Clean the auger housing thoroughly to remove all pellet dust.

TROUBLESHOOTING GUIDE

25