HeatPack Furnace Installation and Operation Manual

61

12 Troubleshooting

PROBLEMS

CAUSES

SOLUTIONS

Heating inefficient during the

first combustions. Lack of

draft.

Improper adjustment of the

barometric damper (opened

too wide). Chimney flue

restriction (too long. 90

o

elbows)

Adjust the damper, minimize

the smoke pipe length and use

45

o

elbows.

Furnace burns well, warm air

plenum is very hot but there is

not much heat coming out in

the room.

Improper installation of the

ducts, low static press0ure,

unbalanced system (too many

warm air outlets and not

enough fresh air return).

Rearrange the ducting to

respect the minimum static

pressure of 0.20 in. W.C. (50

Pa)

Furnace consumes a lot of

wood.

Damper switch left always on.

The thermostat which controls

the damper is continuously

activated or is too close to a

source of cold air. Damper not

properly adjusted. House not

insulated enough. Ash plug

and drawer are not tightly

closed. Furnace too small for

the surface to be heated.

Unbalanced ventilation system,

very little heat where the

thermostat is located.

If manually controlled, install a

wall thermostat. Relocate the

thermostat. Rebalance the

ventilation system in order to

increase the air flow in the

room where the thermostat is

located.

A lot of creosote, moderate

heat output.

Wet wood, lack of draft.

Barometric damper not

properly adjusted. Restriction

in the furnace or chimney.

Use dry wood. Adjust the

barometric damper. Clean the

chimney, flue pipe and the

furnace exchangers.

Furnace heats a lot but the

warm air duct does not get hot.

Wet wood or low grade wood.

No static pressure.

Unbalanced ventilation system.

Use dry wood. Rearrange the

ventilation system correctly.

Primary air inlet damper never

opens.

Furnace is not plugged-in.or an

electrical component is faulty.

Make sure the furnace is

plugged-in a functional power

outlet. Test and replace if

necessary, control switch,

thermostat, and damper motor.

Summary of Contents for HeatPack DF00500

Page 29: ...HeatPack Furnace Installation and Operation Manual 29...

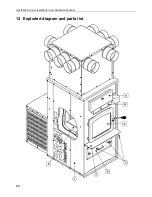

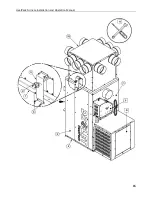

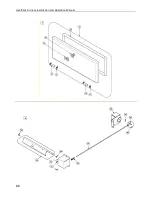

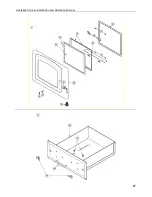

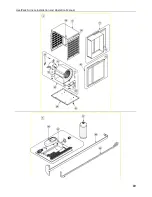

Page 64: ...HeatPack Furnace Installation and Operation Manual 64 13 Exploded diagram and parts list...

Page 65: ...HeatPack Furnace Installation and Operation Manual 65...

Page 66: ...HeatPack Furnace Installation and Operation Manual 66...

Page 67: ...HeatPack Furnace Installation and Operation Manual 67...

Page 68: ...HeatPack Furnace Installation and Operation Manual 68...

Page 69: ...HeatPack Furnace Installation and Operation Manual 69...

Page 75: ...HeatPack Furnace Installation and Operation Manual 75 14 2 1 Technical data HeatPack...

Page 76: ...HeatPack Furnace Installation and Operation Manual 76...