DOC-0128 Rev F

© 2017 DROPLET MEASUREMENT TECHNOLOGIES

4 6

8.4.2

OPC Calibration Procedure

Start the CCN-200, then perform the procedures below for each OPC.

1.

Turn off the liquid supply pump.

2.

Set conditions for a low supersaturation of 0.1%, and start the airflow rate.

3.

To speed the drying process, use a drying tube such as a Drierite tube. Connect this to the

inlet or, if a drying tube is not available, use air and run the CCN for about 15 minutes to

reduce the humidity in the tube.

4.

Connect the aerosol generator to the sample inlet and start the aerosol generator.

5.

Note the bin where the calibration particles are measured. A good calibration exists if the

particles are in the proper bin or slightly high. If the particles are in a lower size bin, the OPC

could be dirty and will need cleaning and recalibration. Contact Droplet Measurement

Technologies.

6.

Restart CCN-200 to calibrate other OPC or for normal operation.

8.4.3

OPC Cleaning Procedure

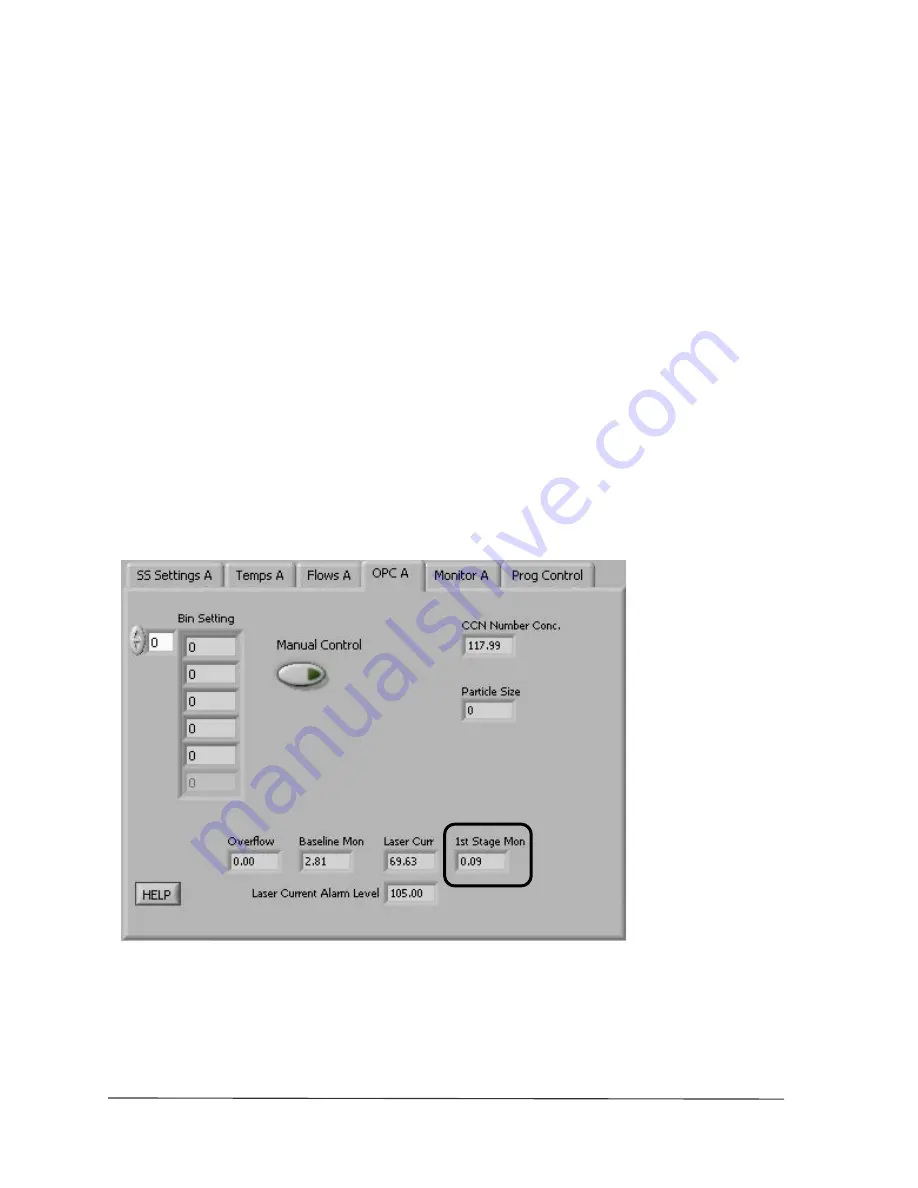

If after running the OPC dry air recirculation pump on high for 12 hours, the

1

st

Stage Monitor

voltage

for either OPC is still at or near 5.0 V, there may be water droplets on the window between the laser

and OPC. The

1

st

Stage Monitor

voltage is displayed in the bottom right of the OPC tab for each

column. Figure 29 shows the

1

st

Stage Monitor

voltage for column A.

Figure 29: OPC 1st Stage Monitor Voltage