4

6.

UNPACKING AND INSTALLING THE PANEL

6.1 UNPACKING

Once a suitable location has been found to install the unit, remove the panel from package. Check the unit

has not been damaged during transportation or storage. No particular disposal procedures are necessary

as packaging materials are no dangerous for health or environment. However, package should be disposed

of in accordance with regulations that may be in force in your area or state.

6.2 INSTALLING

VIP4Tools/Oil

PANEL

In order to facilitate any maintenance intervention and to avoid unnatural posture or the possibility of

sustaining impacts, install the machine in a reachable position.

Allow sufficient space for the installation, leaving minimum 100 mm (3.93 in.) around the unit.

Do not install the unit in aggressive or explosive/inflammable environments or on vibrating surfaces.

To install the panel, use only the supplied bracket provided with two holes for screws Ø6mm (Ø 0.23

in.), see

Dimentions ch.12

.

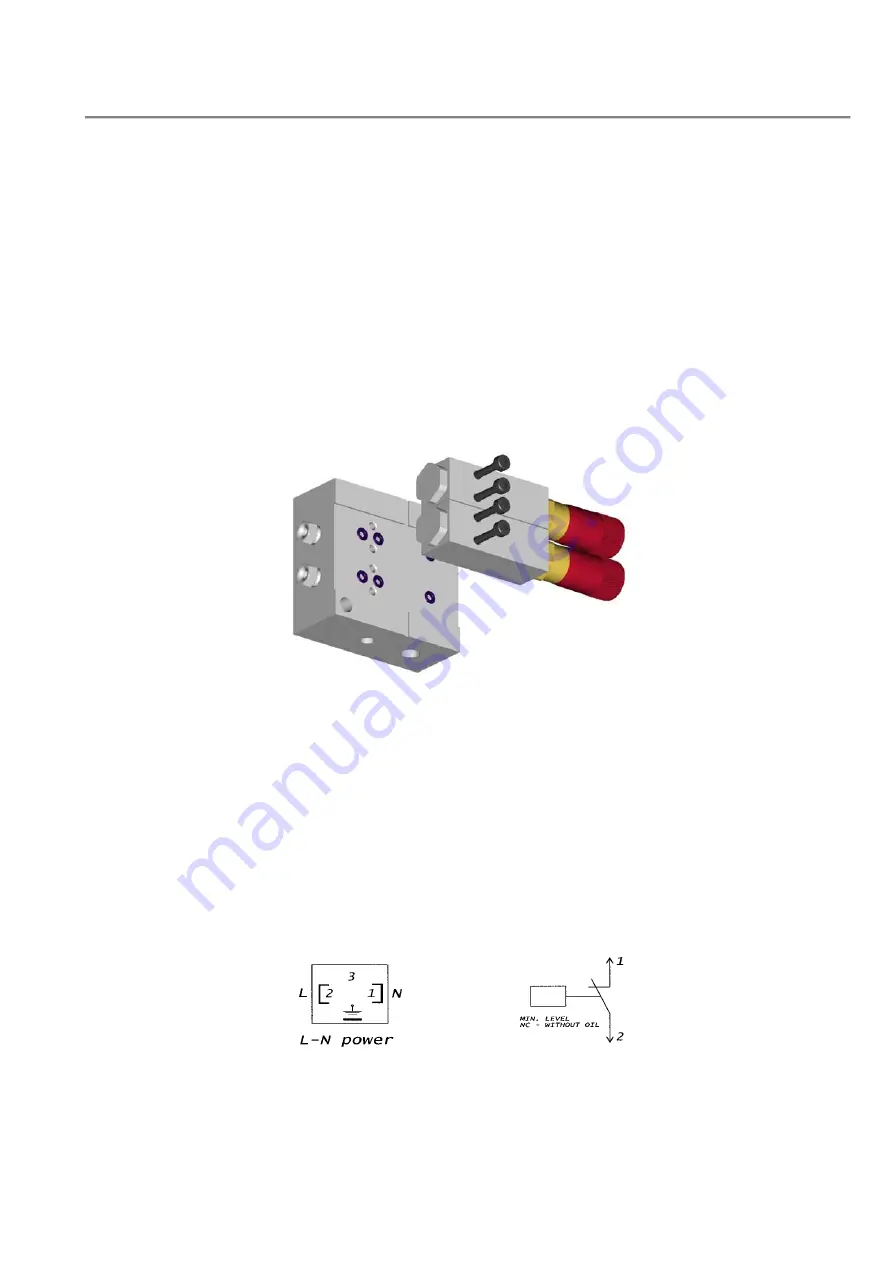

6.3 INSTALLING MINI-PUMPS ON THE SUB-BASE

Mini-pumps are assembled to sub-base by means of two fixing screws. Be careful to correctly posistion o-

rings between mini-pumps and sub-base, as shown in the figure below:

6.4 HYDRAULIC FITTING

Connect each mini-pump to the corresponding lubrication point using Ø4mm (Ø0.15 in.) nylon piping

(furnishable by Dropsa).

6.5 PNEUMATIC CONNECTIONS

Connect the air inlet to push-in by mounting Ø 6mm (Ø 0.23 in.) nylon piping on the sub-base. A check valve

must be arranged in order to stop air supply.

6.6 ELECTRIC WIRING

Samba level is the only electric connection for VIP4Tools/Oil (see the electric diagram below).

At the end of all connecting operations, make sure that pipes and wires are safe from impacts and

carefully fixed.