Parachute Manual for DJI M600 and M600 pro

4 Application

4.1 Functional tests after installation

After finishing the installation of the DRS-M600 parachute rescue systems you

should run some basic tests before taking-off. These tests ensure the installa-

tion was successful and all components operate properly. For these tests it is

necessary to switch on the engines without actually talking off. Therefor we

strongly recommend to remove the propellers to prevent any injuries.

Put the deployment container under tension as described in chapter "Load-

ing and unloading the parachute" until you reached step number 3 - without

loading the parachute into the tube. Instead you should put some dummy load

(like a bottle filled with water) inside.

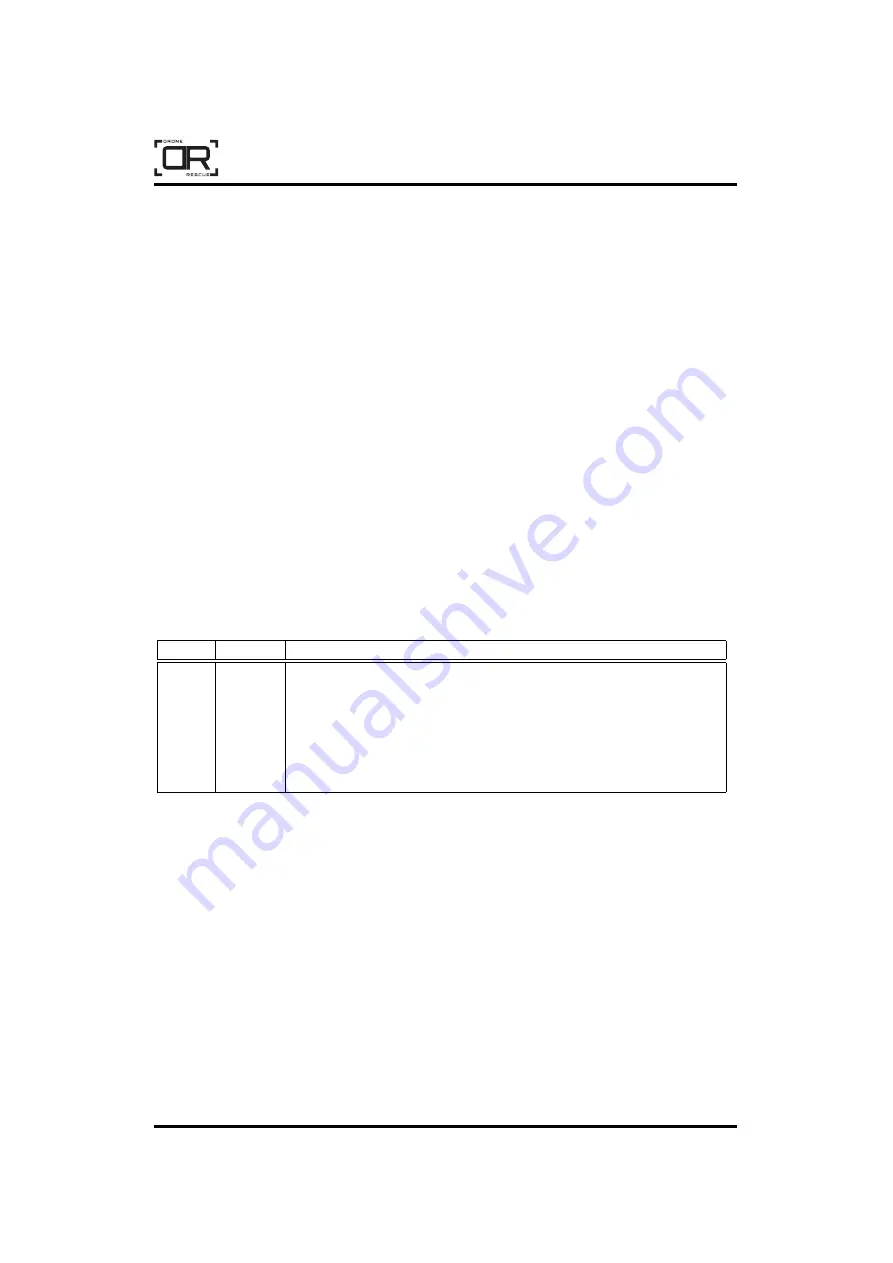

4.2 Visual status signal

The DRS-M600 system is equipped with a three-color RGB (Red, Green, Blue)

LED (Light emitting diode) to inform the pilot about the internal system status

as described in table 1.

Color

Type

Description

Blue

Flashing

System initializing.

Blue

Solid

System on, waiting for valid RC input signal.

Green

Flashing

System armed - ready for take-off. Manual deployment possible.

Green

Solid

System armed take-off detected. Automatic failure detection active.

Red

Flashing

System error.

Red

Solid

Parachute deployed.

Purple

Flashing

Firmware update in progress.

Table 1:

LED status codes

If the status LED will not switch to solid green after taking off, the parachute

will not get deployed in case of emergency and it is highly recommended to

land the UAV and check signals between the RC-Receiver/Flightcontroller and

the DRS system.

4.3 Acoustic status signal

Whenever the parachute will get deployed, the DRS system will inform the en-

vironment about the descending UAV using a loud acoustic signal. You will also

hear a short beep when the take-off was detected.

18/27