English

I NS TAL LAT ION M ANUA L

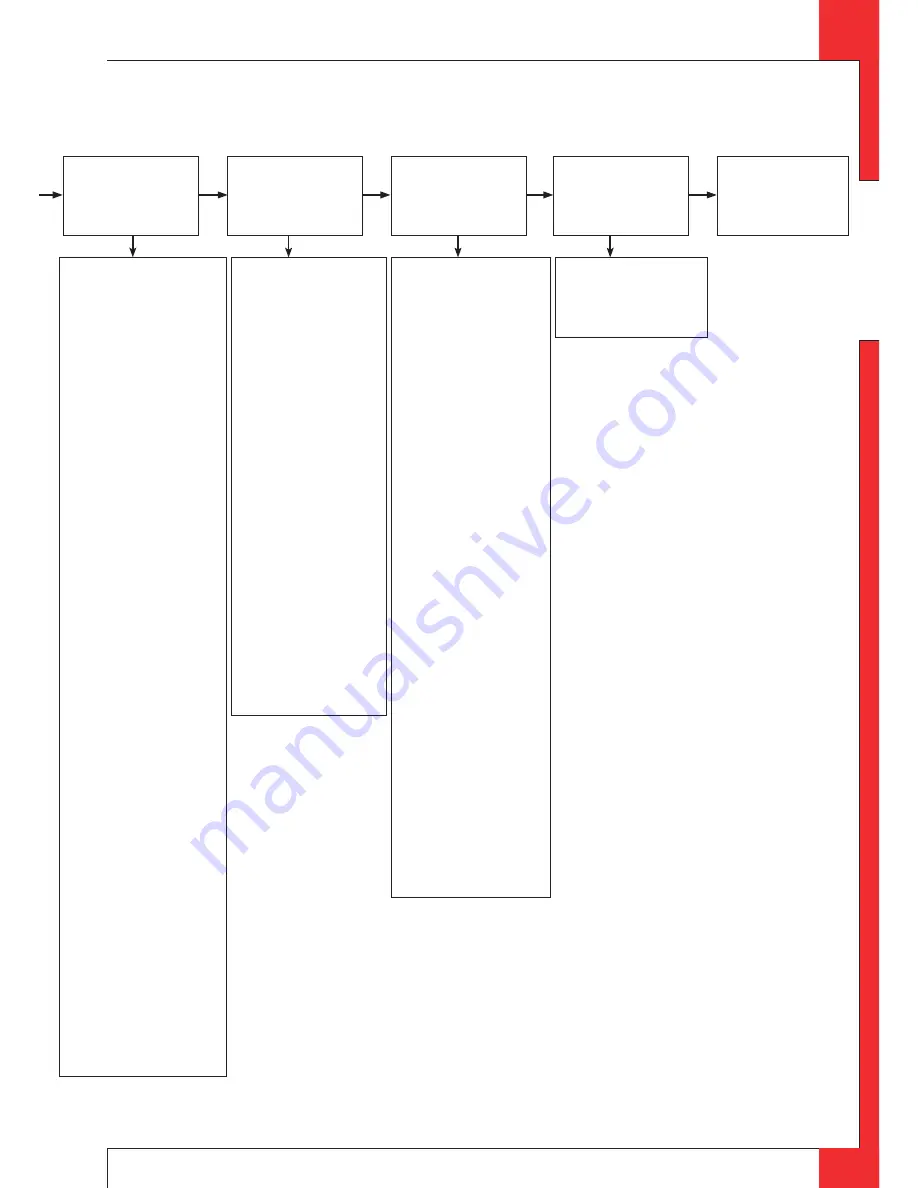

2.12 Does appliance switch off

exactly 22 sec after

servomotor starts running?

2.19 Replace gas control

(thermo-electric valve does not

shut down quick enough because

of some permanent magnetism)

2.14 Does main burner go out

after 'some time'?

2.18 Can fire be switched off?

2.20 Perfect!

You have a well functioning

fire

2.16 Is flame picture OK?

2.13 Check cross lighting main

burner and 2nd thermocouple

system.

Measure voltage of 2nd

thermocouple

-

Check voltage in mV, 22 sec

after servomotor starts to run,

c.q. just before fire goes out.

Glass window to be mounted!

-

Measure between black wire +

earth point on gas control.

-

Requirement: voltage >5 mV

after rectification actions.

Voltage 0 mV

-

2nd couple defective.

-

Cross ligting main burner very

slow. Take actions "Cross

lighting too slow" (see below),

before taking any further

action!!

Voltage <1,8 mV

-

Cross ligting main burner too

slow. Take actions "Cross

lighting too slow" (see below),

before taking any further action!

-

2nd couple barred. Check:

- 2nd couple free of vermiculite,

chips or pebbles;

- position of logs or pebbles;

- burner holes under 2nd couple

open.

-

2nd couple defective (cross

lighting OK, but voltage creeps

up too slow).

-

Flames instable, see 2.15.

Rectify, before any other action

is taken!!

-

Burner pressure (too high or too

low).

-

2nd couple not positioned

correctly in flame.

Bend into correct position (see

manual).

-

2nd thermocouple positioned

correctly (see manual). Bend

into flame (only if cross lighting

and flame picture are OK!! See

2.17).

Voltage > 1,8 mV

-

Receiver defective. Replace.

Cross lighting of main burner too

slow

Measure the time in sec from start

running of servomotor till the flame

reaches the 2nd couple.

Requirement: the flame must be in

position at the 2nd couple <10 sec.

If not, check:

-

2nd couple free from

vermiculite, chips or pebbles;

-

position of logs or pebbles;

-

burner holes (locally) blocked.

Remove vermiculite dust.

-

vermiculite missing or not

evenly distributed across

burner(s);

-

chips on burner;

-

lack of combustion air. See 2.15.

-

cross lighting in low setting

(possible when thermostat

function is used).

2.15 Check

Gas supply

-

Supply pressure does not

drop away as main burner (or

other appliance) lights,

causing pilot flame to shorten.

-

Burner pressure (too high or

too low).

Flames instable (suffocating, lack

of air).

Dancing flames on burner.

Lack of combustion air. Check:

-

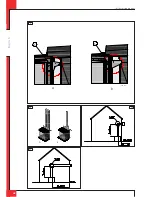

flue system permissible;

-

proper flue terminal used,

make should be 'DRU';

-

terminal correctly sited on

roof or wall relative to

obstructions;

-

integrity of flueing system (no

interruptions, not barred,

cobwebs);

-

air inlet guides;

-

flue restrictor/damper;

-

throttle rings.

See manual for specific

requirements.

PowerVent®

Possibly not enough draught. Check

if pressure difference set too high.

Consult PowerVent® installation

manual.

Pilot burner

-

Pilot burner dirty. Weak pilot

flame being drawn away by

flames main burner.

Clean with compressed air.

See 2.04.

2.17 Check

Flames: too low

-

Supply pressure does not

drop away as main burner or

other appliances in the

building light, causing flames

to shorten.

-

Burner pressure (too low).

-

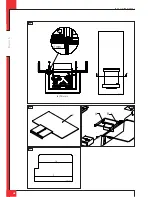

False air: Check soundness

glass window gasket/

soundness of the connection

of the glass panes of

two/three sided appliances

(no slots allowed).

Flames: too high

-

Line pressure.

-

Burner pressure.

Flames: no even distribution

or

out on part of the burner(s)

-

Position of logs or pebbles.

-

Burner holes (locally) blocked.

Remove vermiculite dust.

-

Vermiculite not distributed

evenly across burner(s).

-

Adjustment of throttle ring(s).

Flames: too blue/too yellow or

sooting

-

Air inlet guides.

-

Flue restrictor/damper.

-

Adjustment of throttle ring(s).

Flames: suffocating: lack of air

You see dancing flames on burner,

seeking for air. See 2.15.

Flame picture 'restless'

Indication of too much draught.

Check:

-

adjustment of appliance

damper and air inlet guides);

vertical flue length allowed

(<12 m);

-

window glass not mounted

gas tight.

PowerVent®? Check:

Possibly too much draught. Check:

-

Pressure difference set too

high.

-

Silicon pressure measurement

hoses leaking.

Consult PowerVent® installation

manual for more info.

No

No

Yes

Yes

No

Yes

Yes

No

UK

Summary of Contents for G20

Page 28: ...E n g l i s h INSTALLATION MANUAL UK A C B C 38c 1461 A B 38c 1 462 3a 2 3b 3c ...

Page 32: ...E n g l i s h INSTALLATION MANUAL UK E 38p 0029 A B C D A 38p 0030 B 38p 0031 10a 10b 10c ...

Page 33: ...E n g l i s h INSTALLATION MANUAL UK C 38p 0032 D 38p 0033 E 38p 0034 10d 10e 10f ...

Page 34: ...E n g l i s h INSTALLATION MANUAL UK 38p 0035 38p 0062 10g 10h ...

Page 37: ...E n g l i s h INSTALLATION MANUAL UK 38p 0181 5mV 38p 0182 20mm 25mm 38c 1471 1 16 17 18 ...

Page 38: ...E n g l i s h INSTALLATION MANUAL UK ...