QBC STAR System Operator’s Manual

6000-300-000 5–6

Level 1

Level 2

Level 3

Min

Target

Max

Min

Target

Max

Min

Target

Max

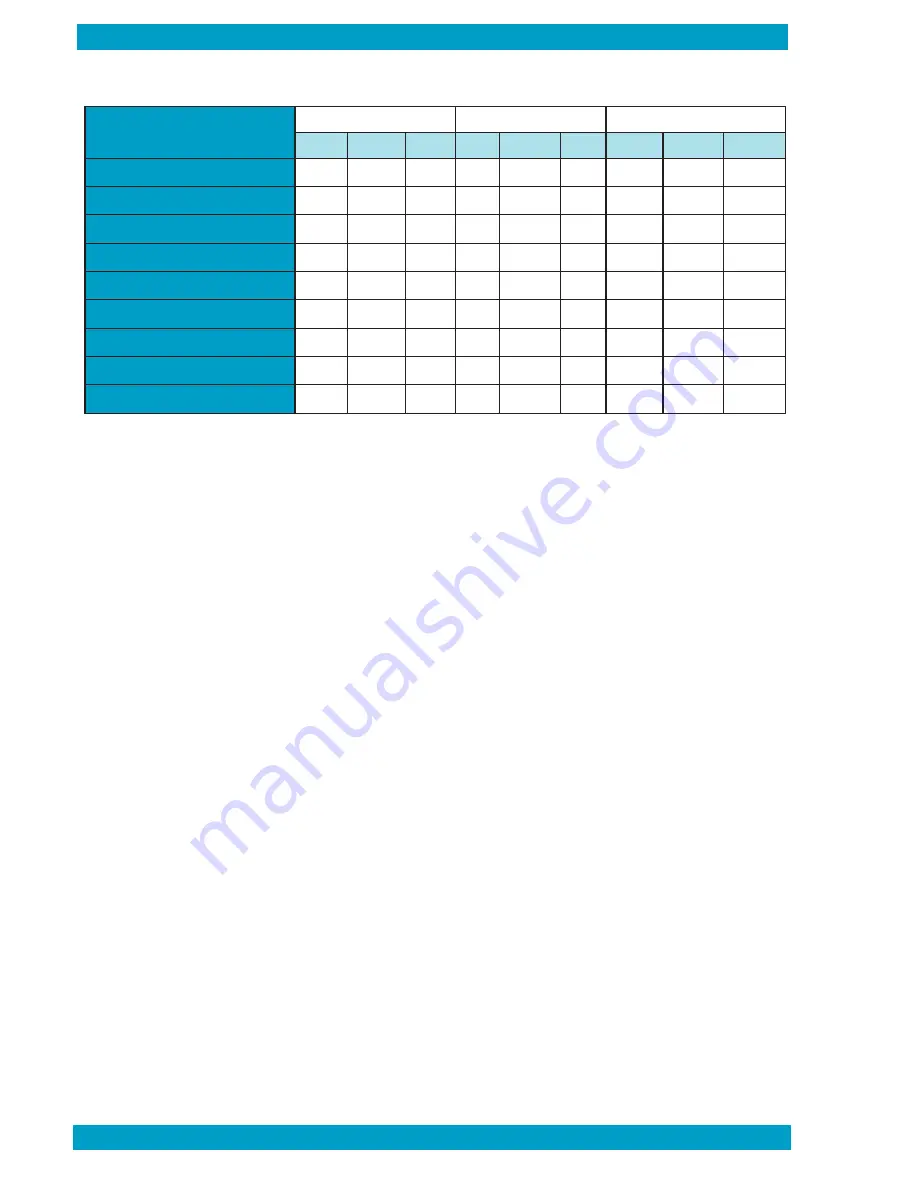

HCT (%)

36.9

37.9

38.9

44.9

45.9

46.9

65.1

66.1

67.1

HGB (g/dL)

12.3

12.9

13.5

14.8

15.6

16.4

20.6

21.7

22.8

MCHC (g/dL)

31.6

34.0

36.6

31.6

34.0

36.5

30.7

32.8

35.0

PLT (x 10

9

/L)

90

100

110

342

360

378

615

647

679

WBC (x 10

9

/L)

4.6

5.7

6.8

9.5

10.6

11.7

48.5

53.5

58.5

GRAN (x 10

9

/L)

2.2

2.7

3.2

6.0

6.5

7.0

28.3

31.3

34.3

%GRAN

38

47

57

56

61

67

54

59

63

L/M (x 10

9

/L)

2.4

3.0

3.6

3.5

4.1

4.7

20.2

22.2

24.2

%L/M

43

53

62

33

39

44

37

41

46

6000-300-000 5-6

The QC label tolerances are shown in the table below.

Analytical Quality Control

The QBC STAR Centrifugal Hematology System has multiple built-in analytical quality control (QC)

systems that maintain the overall system integrity and the quality of the test results it produces.

The QBC STAR System has five analytical quality control elements:

1. Factory calibration. System calibration is set during manufacture and cannot be altered by

the user.

2. Instrument Power On Self-Test. This test assures that each time the instrument is turned

on, the computer, memory, optics, and motors are fully functional. Should you choose to

leave the system on continuously; the test will automatically be repeated every 8 hours if

the door is closed. A tri-level quality control label (QC label), designed to simulate 3 hema-

tology specimens (simulating low cell counts, normal cell counts, and elevated cell counts)

tests the system’s optics against values established at the time of manufacture. At the end

of the power on self-test, the instrument prints the values obtained from reading the QC

label. The values may be plotted to evaluate for shifts or trends in the data. The instrument

will flag any results that are outside the set limits, print an error code, and automatically

shut down operation of the instrument until the problem is corrected and a valid power on

self-test is performed.

3. Electronic QC (during each sample run). The built-in electronic checks during each sample

run confirm the proper centrifuge speed, centrifugation profile, system communications,

and internal temperature.

4. Sample Preparation QC (during each sample run). The built in checks confirm that the QBC

STAR tube has not been previously processed. Tests confirm that the tube assembly is

the proper length, the float is present and the correct length, and the tube is filled with the

correct amount of blood.

5. Reagent QC (during each sample run). These built-in checks evaluate sample and reagent

integrity using the data from the optical scan. This includes tests for fluorescent signal

intensity, proper number, size and location of the cell layers and interface sharpness.

When these analytical quality control checks are successfully completed, the status of the instru-

ment’s analytical QC is printed on the patient record as “STAR Analytical QC: Passed.”Results are

reported only if all of the analytical quality control requirements have been satisfied.

Summary of Contents for QBC STAR

Page 14: ...THIS PAGE INTENTIONALLY LEFT BLANK...

Page 28: ...THIS PAGE INTENTIONALLY LEFT BLANK...

Page 40: ...QBC STAR System Operator s Manual 6000 300 000 4 12 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 50: ...THIS PAGE INTENTIONALLY LEFT BLANK...

Page 72: ...6000 300 000 A 1 8 Appendices 6000 300 000 8 1...

Page 74: ...THIS PAGE INTENTIONALLY LEFT BLANK...

Page 76: ...THIS PAGE INTENTIONALLY LEFT BLANK...

Page 78: ...THIS PAGE INTENTIONALLY LEFT BLANK...

Page 80: ...THIS PAGE INTENTIONALLY LEFT BLANK...