6000-300-000

7–7

7 – Troubleshooting

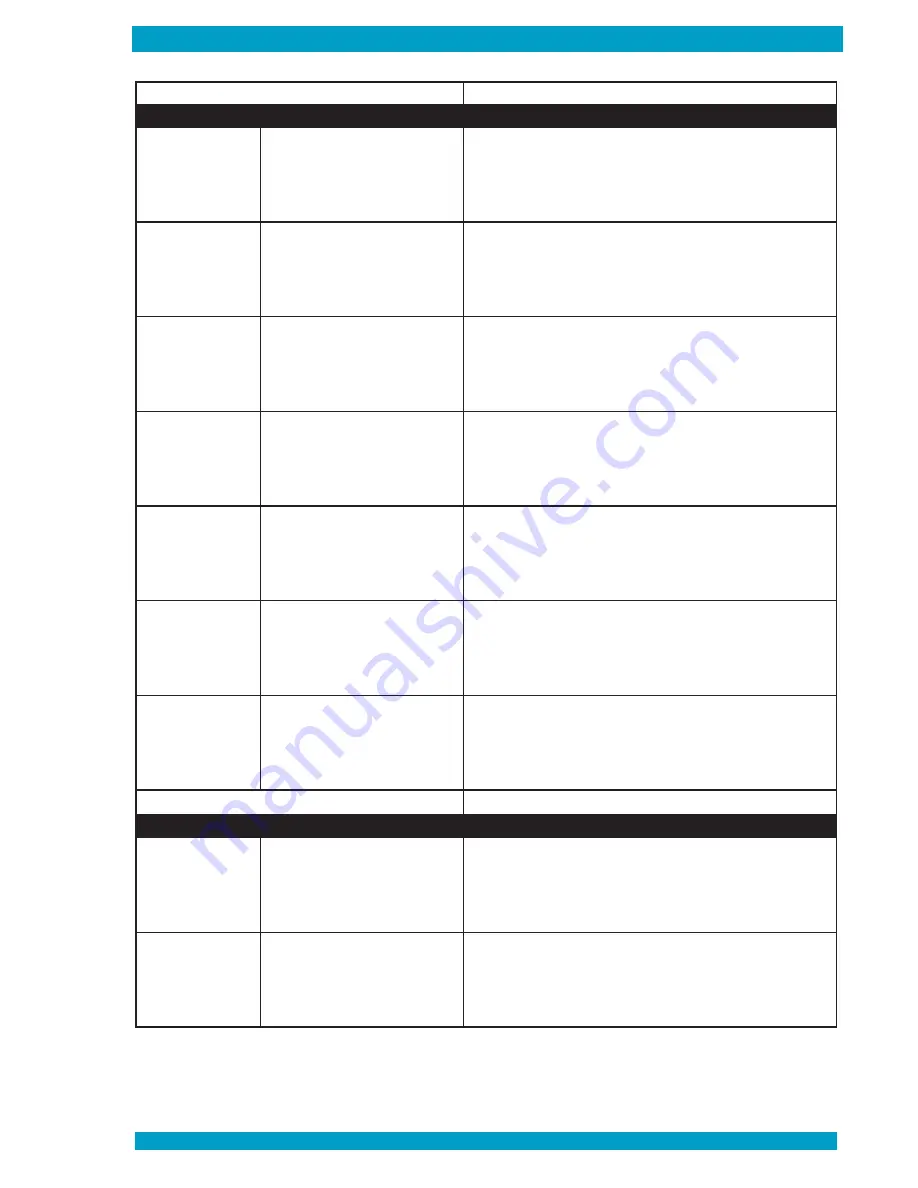

E3 - Camera Board

Error Number

Description

Corrective Action

300

Camera board error

1. Record the error message displayed on the LCD screen

2. Export the support file (Ref. page 2-8)

3. Power down the instrument (Ref. page 4-10)

4. Turn the instrument Power on (Ref. page 4-2)

5. If the error persists contact Technical Support

301

Camera board device driver error

1. Record the error message displayed on the LCD screen

2. Export the support file (Ref. page 2-8)

3. Power down the instrument (Ref. page 4-10)

4. Turn the instrument Power on (Ref. page 4-2)

5. If the error persists contact Technical Support

303

Camera board data reading error

1. Record the error message displayed on the LCD screen

2. Export the support file (Ref. page 2-8)

3. Power down the instrument (Ref. page 4-10)

4. Turn the instrument Power on (Ref. page 4-2)

5. If the error persists contact Technical Support

304

Camera board parameter

communications error

1. Record the error message displayed on the LCD screen

2. Export the support file (Ref. page 2-8)

3. Power down the instrument (Ref. page 4-10)

4. Turn the instrument Power on (Ref. page 4-2)

5. If the error persists contact Technical Support

305

Unable to verify commands sent

to camera error

1. Record the error message displayed on the LCD screen

2. Export the support file (Ref. page 2-8)

3. Power down the instrument (Ref. page 4-10)

4. Turn the instrument Power on (Ref. page 4-2)

5. If the error persists contact Technical Support

311 thru 316

Camera board communication

errors

1. Record the error message displayed on the LCD screen

2. Export the support file (Ref. page 2-8)

3. Power down the instrument (Ref. page 4-10)

4. Turn the instrument Power on (Ref. page 4-2)

5. If the error persists contact Technical Support

317

Camera initialization error

1. Record the error message displayed on the LCD screen

2. Export the support file (Ref. page 2-8)

3. Power down the instrument (Ref. page 4-10)

4. Turn the instrument Power on (Ref. page 4-2)

5. If the error persists contact Technical Support

E4 - I/O Board

Error Number

Description

Corrective Action

400

I/O board error

1. Record the error message displayed on the LCD screen

2. Export the support file (Ref. page 2-8)

3. Power down the instrument (Ref. page 4-10)

4. Turn the instrument Power on (Ref. page 4-2)

5. If the error persists contact Technical Support

401

Software version error

1. Record the error message displayed on the LCD screen

2. Export the support file (Ref. page 2-8)

3. Power down the instrument (Ref. page 4-10)

4. Turn the instrument Power on (Ref. page 4-2)

5. If the error persists contact Technical Support

Summary of Contents for QBC STAR

Page 14: ...THIS PAGE INTENTIONALLY LEFT BLANK...

Page 28: ...THIS PAGE INTENTIONALLY LEFT BLANK...

Page 40: ...QBC STAR System Operator s Manual 6000 300 000 4 12 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 50: ...THIS PAGE INTENTIONALLY LEFT BLANK...

Page 72: ...6000 300 000 A 1 8 Appendices 6000 300 000 8 1...

Page 74: ...THIS PAGE INTENTIONALLY LEFT BLANK...

Page 76: ...THIS PAGE INTENTIONALLY LEFT BLANK...

Page 78: ...THIS PAGE INTENTIONALLY LEFT BLANK...

Page 80: ...THIS PAGE INTENTIONALLY LEFT BLANK...