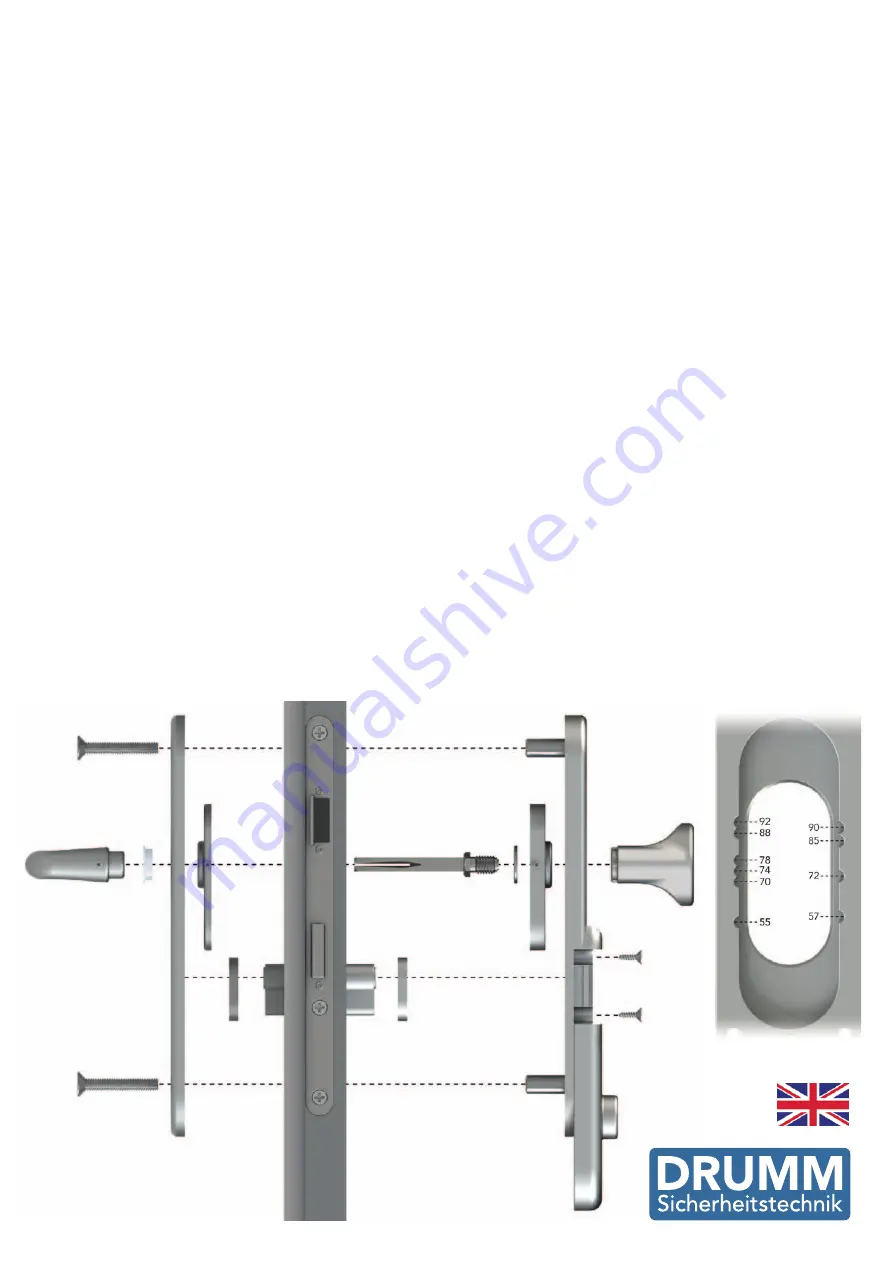

Assembly instructions for GEMINY Europe model

The enclosed screws are suitable for door thicknesses from 40-52 mm. Longer screws and longer half spindles are available for

thicker doors. The selected screw length should provide a screw-in depth of at least 8 mm.

Adjustment of the distance

Use the dimension table to determine the applicable adjustment. Partly screw in the grub screw on the correct side of the insert for

the inner and outer plate. Place the insert in the inner and outer plate. The adjustment dimension refers to the distance from the

middle of the door handle to the middle of the profile cylinders core. The dimensions 72 and 92 mm are standard in Germany.

88 mm is standard in Austria for example.

Preparation of the inner plate

Attach the handle bearing (plastic ring) to the outside of the insert. It prevents subsequent wiggling of the door handle. Insert the

cylinder template.

Preparation of the outer plate

Attach the knob to the outer plate by means of the spindle and the washer. Tighten the spindle with a suitable hexagon spanner, so

that it is secure. Insert the cylinder template.

Assembly of the door fitting

1. Remove the existing fitting from the door.

2. Push the inner plate as a jig on the cylinder on the inside and the outside of the door, align vertically and mark the drill holes for

the fixing screws with a scriber.

3. Next remove the profile cylinder and the mortise lock from the door. This prevents chips from getting into the mortise lock

during drilling and adversely affecting its function.

4. Drill holes with a diameter of 10 mm through the door from both sides at the scribed points.

The drill holes go past the mortise lock.

5. Drill out the top and bottom hole on the outside of the door as a blind hole with a diameter of 13-14 mm and a depth of

approx. 25 mm. Remove the drill chips and refit the mortise lock and the profile cylinder.

6. Loosely screw the outer and inner plate on the door but do not tighten. Ensure that the handle bearing and the profile cylinder

are not twisted in the process.

7. Now tighten the screws. Push the handle on the half spindle from the inside and tighten with the grub screw.

8. Carry out a closing test with the open door.

9. After the function test, check all the screws and retighten if necessary. Over-tightened screws can restrict the function of the

mortise lock. In this case, you can undo the screws slightly.

10. The four wood screws around the cylinder serve as an additional fastening.