Page 5

For technical questions, please call 1-888-866-5797.

Item 63477

Maintenance

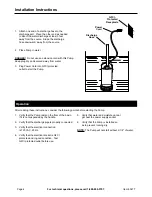

TO PREVENT SERIOUS INJURY FROM ACCIDENTAL OPERATION:

Unplug the Pump from its electrical outlet before performing any

inspection, maintenance, or cleaning procedures.

If the Pump is moved during operation, flush it out with clean water after every use.

Quarterly Maintenance

The below maintenance must be performed at least once every 3 months under optimal conditions.

For frequent use, or dirty areas, more frequent maintenance is required.

1. Clean sludge and debris from the bottom of the basin.

2. Clean sludge/debris from the impeller.

3. Make sure discharge pipe is free from leaks.

4. Make sure check valve is functioning properly.

Troubleshooting

Problem

Possible Causes

Possible Solutions

Pump runs, but

will not deliver

any water.

1. Impeller clogged.

2. When starting, the water

height falls too low.

3. Low line voltage.

4. Check valve (sold separately)

stuck or installed backwards.

1. Clean out dirt and debris from impeller.

2. There must be at least 2-1/4" deep water

for the Pump to operate properly.

3. Consult an electrician.

4. Remove and examine check valve.

Pump won’t

start or run.

1. Check power connections

and circuits/fuses.

2. Water level too low.

3. Impeller clogged.

4. Defective motor.

1. Consult an electrician.

2. Allow water level to rise above 2-1/4",

or move Pump to a lower location.

3. Clean out Impeller.

4. Have a qualified service technician repair or replace.

Excessive noise

or vibration.

1. Debris in impeller.

2. Discharge hose restricted.

1. Clean impeller.

2. Clean Pump and discharge hose.

Pump starts

and stops too

frequently.

1. Water temperature too high.

2. Check valve (sold separately)

stuck or installed backwards.

3. Back flow of water from

discharge hose.

1. Do not exceed 95° F (35°C) water temperature.

2. Remove and examine check valve.

3. Install or inspect check valve (sold separately).

Follow all safety precautions whenever diagnosing or servicing the tool.

Disconnect power supply before service.