10

Prior to lifting a supply shaft into the laminator, position the T-Slot in the hub on the

machine‟s right side to receive the shaft. The use of an assistant is strongly recommended.

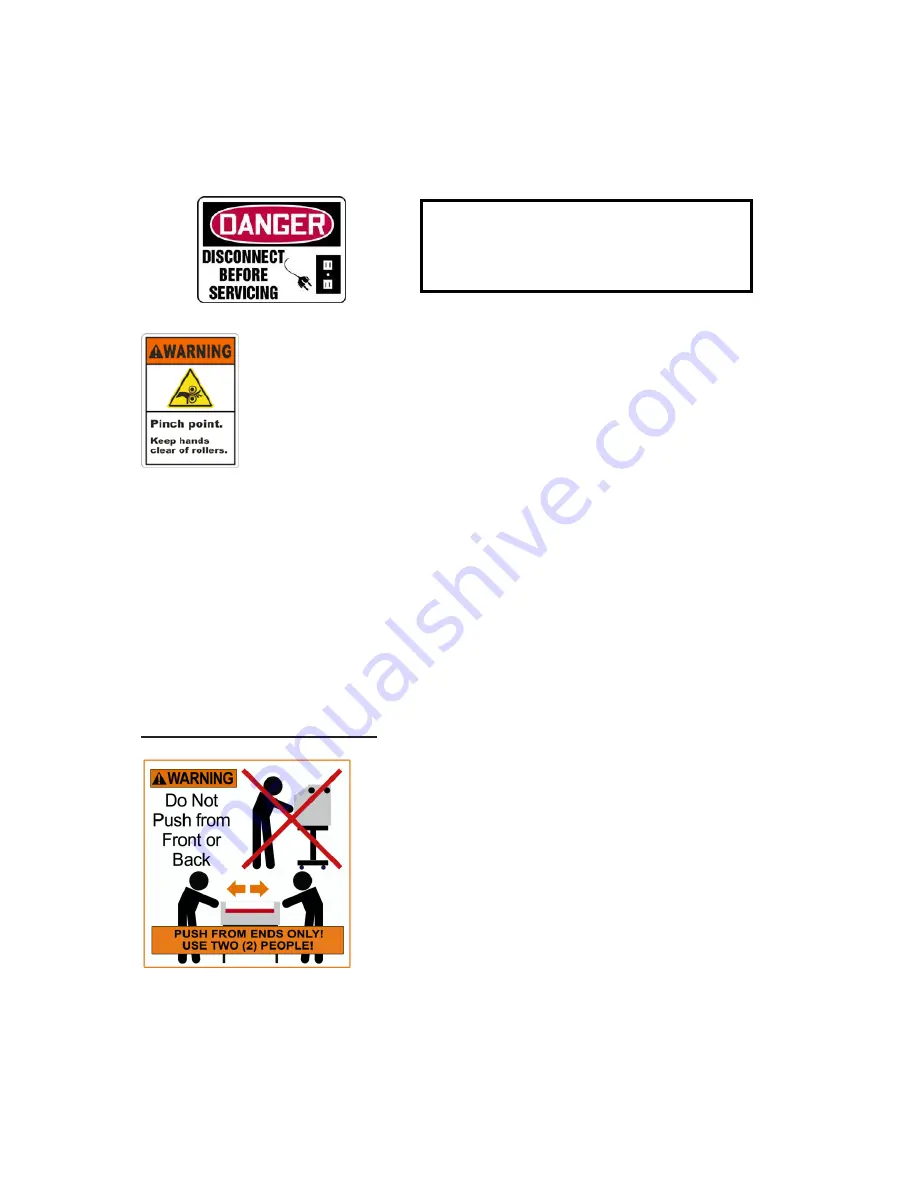

When using a large supply roll, be aware that a pinch hazard can exist

between the top roller and the supply shaft. When working from the rear of

the laminator the operator must be aware of the Nip point of the contacting

rollers and exercise extreme caution to avoid injury.

The sound pressure level

this machine generates at the operators‟ position is less than

70dB.

Keep this manual near the machine for future reference. Also check our website for any

additional or updated safety information. (www.drytac.com)

An instructional DVD and a demonstration/training session from a Drytac representative are

also available so you can become familiar with all the features of your new

Jet

Mounter

™

.

Contact our Customer Service Department for details or if you have any questions about the

operation of this equipment. (Contact information can be found on page 30).

Specific Moving Instructions:

The Drytac

Jet

Mounter

™

44 and 54

should

be handled with

care to avoid personal injury or collateral damage.

Whenever the machine is moved, we

strongly

recommend

utilizing

at least

two people. The adage: “Better safe than

sorry,” applies here.

The

Jet

Mounter

™

stands are designed with fixed wheels on

one side and lockable swivel casters on the other for a very

good reason.

When moving the machine, the movers

should be positioned at both sides. Do not push the

Jet

Mounter

™

from the front or

back!

This eliminates the possibility of having the machine tip over onto the mover or their

helper.

Always

disconnect the laminator from the

power supply before removing any panels

for service.