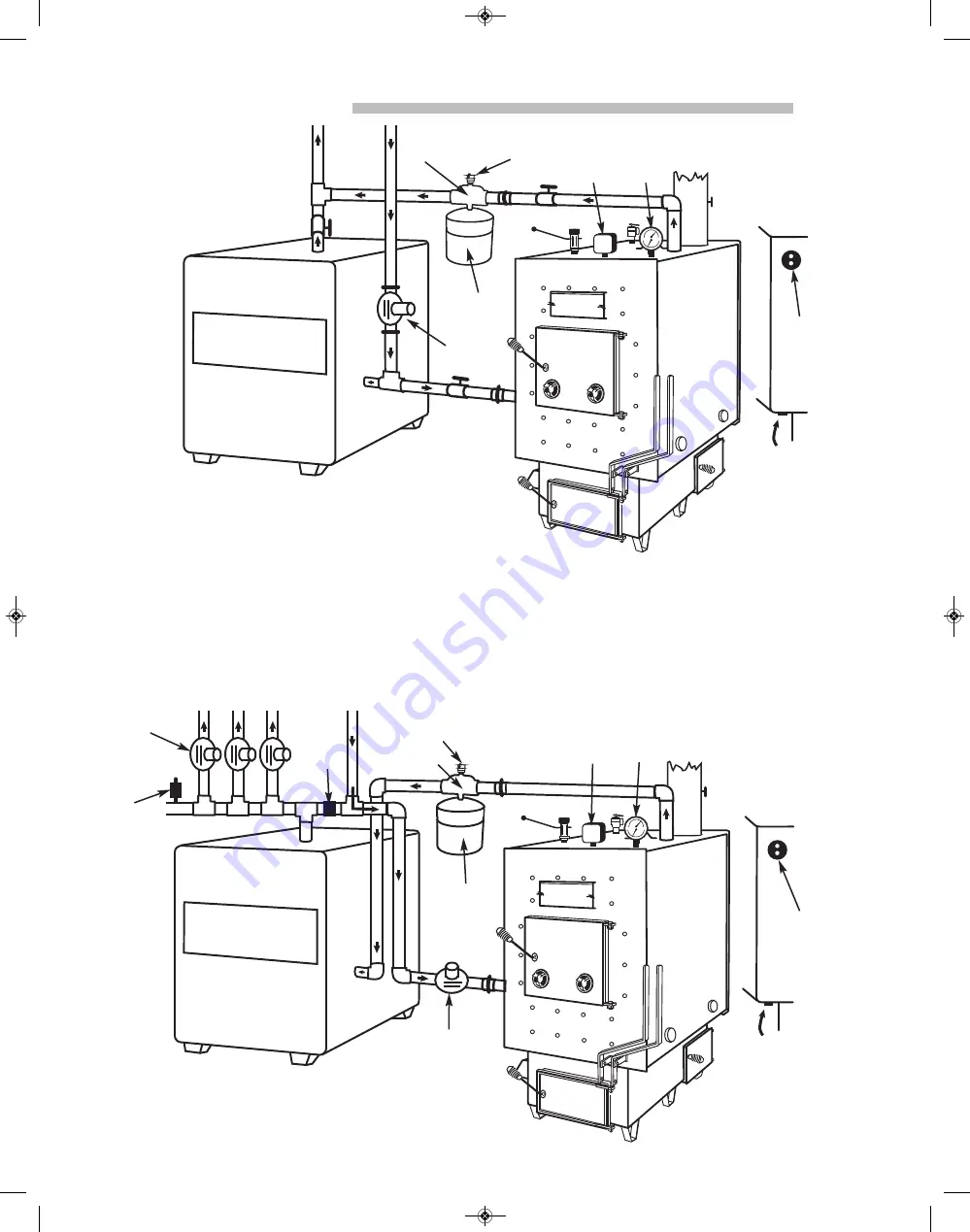

Boiler Installation

Automatic

Air Vent

Air Purger

Back

of

Stove

4 or 5 gallon

per minute

coil optional

2” Inlets

2” Inlets

3/4” Boiler Drain

(under fire box)

Existing Gas or

Oil Boiler

Valve

Valve

Return

Line

Zone

3

Union

Union

Union

T60

Expansion

Tank

Air

Bleed

Valve

Circulator

Pump

#1

#2

#3

#4

#5

#6

4 or 5 gallon

per minute

coil optional

#6

#7

#7

Automatic Air Vent

Air Purger

Back

of

Stove

Circulator

Pump

Circulator

Pumps (3)

3/4” Boiler Drain

(under fire box)

Existing Gas or

Oil Boiler

Valve

Check

Valve

HOT

Union

T60

Expansion

Tank

#1

#2

#3

#4

#5

#1

Samson Control

#2

Temperature - Pressure Gauge

#3

Damper

#4

30# Safety Valve

#5

3/4” Boiler Coil

#6

4 or 5 Gallon Coil

#7

Aquastat

•

All D.S. Boilers must be plumbed by a Qualified Licensed Plumber

or D.S. is not responsible for warranty.

• Failure to follow installation and basic operation will void the warranty

• All Boilers are tested to 100psi.

• Recommended working pressure - 12psi.

•

NOTE:

This Boiler set-up is only a D.S. Machine Design.

Each set-up can be different. Your local plumber could have different

concepts that work also.

Zone

1

Zone

2

NOTE:

Add Boiler Seal to all

new boilers.

On initial setup, fill

boiler with water to the point where

you can still add Boiler Seal mixed

with water and pour into top of

boiler. OR, follow instructions

on Boiler Seal.

4

Power Boiler Manual 2017.qxp_Layout 1 2/13/17 9:32 AM Page 4