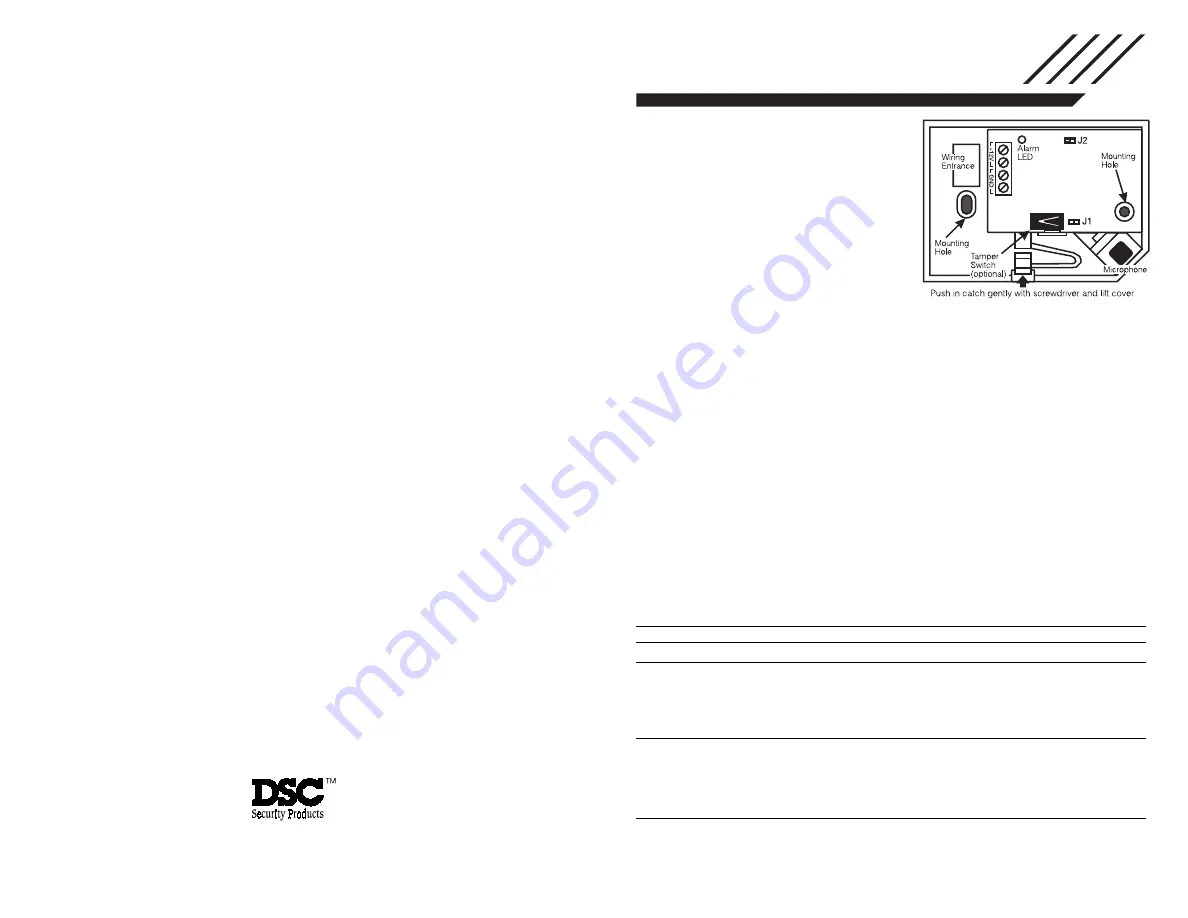

AMA-100

Addressable Glass Break Detector

INSTALLATION INSTRUCTIONS

© 1999 Digital Security Controls Ltd.

1645 Flint Road, Downsview, Ontario, Canada M3J 2J6

Tel. (416) 665-8460 • Fax (416) 665-7498 • Tech. Line 1-800-387-3630

Printed in Canada 29002412 R002

Limited Warranty

Digital Security Controls Ltd. warrants that for a period of twelve months from the date of purchase, the

product shall be free of defects in material and workmanship under normal use and that in fulfillment of any

breach of such warranty, Digital Security Controls Ltd. shall, at its option, repair or replace the defective

equipment upon return of the equipment to its repair depot. This warranty applies only to defects in parts and

workmanship and not to damage incurred in shipping or handling, or damage due to causes beyond control

of Digital Security Controls Ltd. such as lightning, excessive voltage, mechanical shock, water damage, or

damage arising out of abuse, alteration or improper application of the equipment.

The foregoing warranty shall apply only to the original buyer, and is and shall be in lieu of any and all other

warranties, whether express or implied and of all other obligations or liabilities on the part of Digital Security

Controls Ltd. This warranty contains the entire warranty. Digital Security Controls Ltd. neither assumes, nor

authorizes any other person purporting to act on its behalf to modify or to change this warranty, nor to assume

for it any other warranty or liability concerning this product.

In no event shall Digital Security Controls Ltd. be liable for any direct, indirect or consequential damages,

loss of anticipated profits, loss of time or any other losses incurred by the buyer in connection with the

purchase, installation or operation or failure of this product.

Warning

Digital Security Controls Ltd. recommends that the entire system be completely tested on a regular basis.

However, despite frequent testing, and due to but not limited to, criminal tampering or electrical disruption,

it is possible for this product to fail to perform as expected.

The Acuity AMA-100 is an advanced

acoustic glass break sensor, designed to

detect the sounds produced by the

shattering of framed glass. The AMA-100

is the result of an extensive research

program, designed to study the properties

of glass as well as the properties of

sounds produced by the shattering of

framed glass. The result is a detector

which provides exceptional sensitivity and

high false alarm immunity. High quality

manufacturing methods have been

combined with a meticulous final test, to produce a detector which is superior to

any other product of its kind.

Dynamic

Signal Processing* provides accurate detection of plate, laminated,

wired and tempered glass types, while rejecting common false alarm sounds.

The AMA-100 uses a 2-wire connection for power and to communicate with the

control panel. This simplifies wiring and reduces installation cost. The AMA-100’s

low current draw also maximizes the number of devices that can be attached to

an addressable loop.

* Patent Pending

Specifications

Current rating ....................................................... 3.5 mA standby; 5.5 mA with test LED on

Microphone type ............................................................................... Omnidirectional Electret

Dimensions (L x W x H) ................................................ 89 x 64 x 20 mm (3.5 x 2.5 x 0.8 in.)

Operating Environment .................... 0°C-50°C (32°F-122°F); 5%-95% RH, non-condensing

Alarm duration .......................................................................................................... 3 seconds

Detection Level ........................................................................................................ Jumper J2

Control Panels ....... PC4010/4020 v3.x, PC5010, PC5015 v2.X w/PC5100 interface module

Maximum Detection Range

Glass Type

Thickness

Sizes

(l×w)

Level 1

Level 2

Plate/Tempered

1/8–1/4"

18"×18" and up

25ft

15ft

3–6mm

46×46cm and up

7.6m

4.6m

12"×12" to 18"×18"

15ft

10ft

30×30cm to 46×46cm

4.6m

3m

Wired/Laminated 1/4"(6mm)

18"×18" and up

20ft

Do Not Use

6mm

46×46cm and up

6m

Do Not Use

12"×12" to 18"×18"

10ft

Do Not Use

30×30cm to 46×46cm

3m

Do Not Use

FCC COMPLIANCE STATEMENT

CAUTION: Changes or modifications not expressly approved by Digital Security Controls Ltd. could void your

authority to use this equipment.

This equipment generates and uses radio frequency energy and if not installed and used properly, in strict accordance

with the manufacturer’s instructions, may cause interference to radio and television reception. It has been type tested and

found to comply with the limits for Class B device in accordance with the specifications in Subpart “B” of Part 15 of

FCC Rules, which are designed to provide reasonable protection against such interference in any residential installation.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

interference to television or radio reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

•

Re-orient the receiving antenna

•

Relocate the alarm control with respect to the receiver

•

Move the alarm control away from the receiver

•

Connect the alarm control into a different outlet so that alarm control and receiver are on different circuits.

If necessary, the user should consult the dealer or an experienced radio/television technician for additional

suggestions. The user may find the following booklet prepared by the FCC helpful: “How to Identify and

Resolve Radio/Television Interference Problems”. This booklet is available from the U.S. Government Printing

Office, Washington, D.C. 20402, Stock # 004-000-00345-4.

• If the windows in question are covered by drapes or blinds, place the tester

behind the closed window coverings. If the drapes prevent reliable detection,

we suggest that the detector be mounted behind the drapes either on an

adjacent wall or on the ceiling.

• If there are multiple windows, or one large window, activate the tester at the

furthest point on the glass.

When the detector responds consistently, it can be permanently mounted using

the supplied screws.