Operation

71

6.6 MAINTENANCE ALARM

Depending upon module configuration one or more levels of engine maintenance alarm may occur

based upon a configurable schedule.

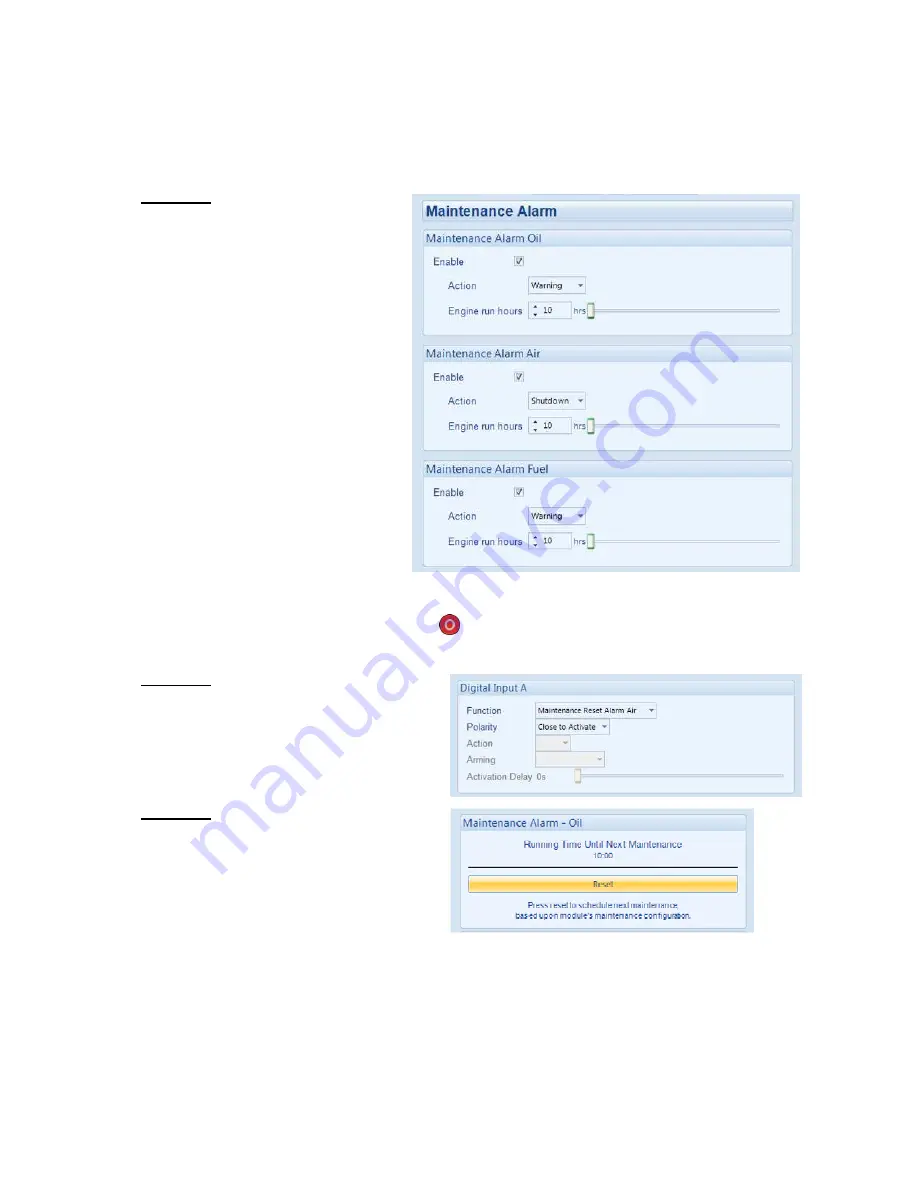

Example 1

Screen capture from DSE Configuration

Suite Software showing the configuration

of the Maintenance Alarm for Oil, Air

and Fuel.

When activated, the maintenance alarm

can be either a

warning

(set continues

to run) or

shutdown

(running the set is

not possible).

Resetting the maintenance alarm is

normally actioned by the site service

engineer after performing the required

maintenance.

The method of reset is either by:

•

Activating an input that has been

configured to Maintenance Reset

Alarm x, where x is the type of

maintenance alarm (Air, Fuel or Oil).

•

Pressing the maintenance reset

button in the DSE Configuration Suite, Maintenance section.

•

Pressing and holding the

Stop/Reset Mode

button for 10 seconds on the desired Maintenance

Alarm status page. This can be protected by a PIN number.

Example 2

Screen capture from DSE Configuration Suite

Software showing the configuration of a digital

input for Maintenance Reset Alarm Air.

Example 3

Screen capture from DSE Configuration Suite

Software showing the Maintenance Alarm

Reset ‘button’ in the DSE Configuration Suite

SCADA | MAINTENANCE section.

Summary of Contents for DSE7110 MKII

Page 34: ...Installation 34 4 2 1 DSE7110 MKII TYPICAL WIRING DIAGRAM 3 PHASE 4 WIRE ...

Page 35: ...Installation 35 4 2 2 DSE7120 MKII TYPICAL WIRING DIAGRAM 3 PHASE 4 WIRE ...

Page 36: ...Installation 36 4 3 ALTERNATE TOPOLOGY WIRING DIAGRAMS 4 3 1 GENERATOR ...

Page 37: ...Installation 37 4 3 2 MAINS DSE7120 MKII ONLY ...